Add: Room 10715,building1,Heping Ginza,No.118 Heping Road,Beilin district,Xi'an city,shaanxi Province.

E-mail: xcmotors@163.com

TEL:+86 13571932715 / +86 15733661508

Whatsapp: +86 13571932715 / +86 15733661508

slip ring wound rotor motor manufacturer

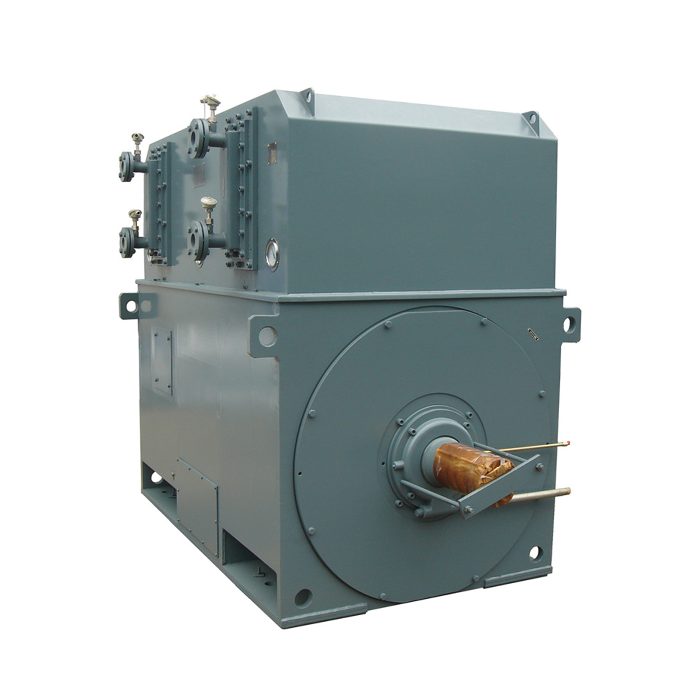

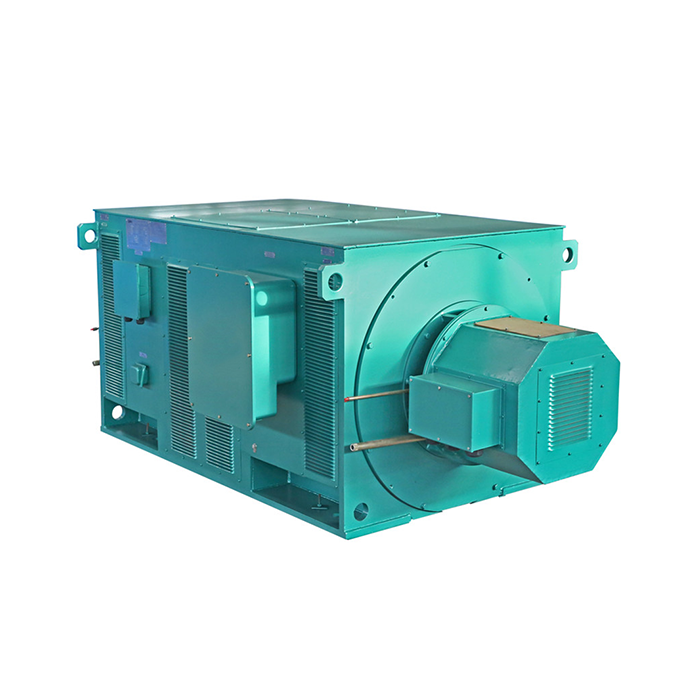

Dependable Slip Ring Wound Rotor Motor

Solutions A leading slip ring wound rotor motor manufacturer, Qihe Xicheng Electromechanical Equipment provides precision-engineered solutions for high-torque and durable industries.

We create custom motors for mining, heavy machinery, and renewable energy systems with over two decades of experience.

Our technical team optimises slip ring wound rotor motor performance using sophisticated materials and winding methods for low maintenance and long life.

From voltage modifications to environmental adaptations, we customize motors to meet your needs.

Every motor is tested to ISO and international safety standards to ensure dependability in difficult environments.

We integrate cutting-edge technology with industry expertise for manufacturing, construction, and energy industries.

Our slip ring wrapped rotor motors improve operations with seamless integration and unparalleled efficiency.

We approach every assignment with quality and customized support.

Quanxi Qihe Xicheng Electromechanical Solutions

This recognized company has provided innovative power equipment solutions to industries globally for over two decades.

The firm specializes in energy-efficient technologies to save operational expenses and ensure reliability.

Expertise in Energy Optimization Advanced methods maximise energy efficiency without affecting power stability.

From factories to infrastructure, customizable designs meet industrial demands.

The Global Partnership Network Industry giants ABB, Siemens, and Wolong collaborate with 114+ foreign motor manufacturers.

This network provides advanced technology and quality control.

Technical Support That Responds Installation, maintenance, and performance optimization are handled 24/7 by dedicated professionals.

Proactive troubleshooting reduces cross-timezone client downtime.

Power Solutions for Sustainability Next-generation equipment has sophisticated monitoring and robust parts.

All systems are rigorously tested for international safety and efficiency certifications.

Reliable energy solutions improve operations and minimize carbon footprints.

Dependable Slip Ring Wound Rotor Motors

for Industry Looking for durable motor solutions that operate well in harsh environments. Qihe Xicheng Electromechanical Equipment is a recognized slip ring wrapped rotor motor manufacturer that makes high-efficiency motors for heavy-duty industrial applications.

We use modern engineering and durable construction to assure mining, cement, and material handling system reliability.

Key benefits of our slip ring wrapped rotor motors: Smooth start-up and accurate speed control reduce equipment mechanical stress.

- Improved heavy-load torque.

Adjustable designs for voltage, power, and environment.

- ISO 9001 and CE certificates ensure quality and safety.

Crushers, conveyors, and lifting machines benefit from our variable-speed motors.

We design solutions to particular operational problems including harsh temperatures, dust, and excessive vibration.

Every motor is tested for durability and low maintenance.

Innovation and customer service have made us a trusted partner for worldwide industries for over two decades.

Learn how our slip ring wrapped rotor motor solutions may improve operations and save costs.

FAQs

1. How does a slip ring wrapped rotor motor work?

Slip rings and brushes link rotor windings to external resistors in a slip ring wound rotor motor. Large applications like crushers and elevators benefit from its smooth speed control and powerful beginning torque. Slip ring wrapped rotor motor maker Qihe Xicheng Electromechanical Equipment offers IP54 protection and voltage ranges up to 690V for industrial dependability.2. Why choose a slip ring motor over standard induction motors?

These motors excel in high-torque, low-speed scenarios. They reduce inrush current by up to 60% compared to squirrel cage motors, protecting equipment during startup. As a leading slip ring wound rotor motor manufacturer, Qihe Xicheng integrates adjustable resistance systems for precise speed management in mining or cement plants.3. What maintenance do slip ring motors require?

Regularly check carbon brushes for wear (replace if under 15mm) and clean slip rings with non-abrasive cloths. Lubricate bearings annually. Qihe Xicheng offers 24/7 technical support and custom maintenance guides to extend motor life—key for harsh environments like marine or steel mills.4. Where are these motors commonly used?

They power cranes, hoists, compressors, and conveyor systems needing variable speed control. Qihe Xicheng’s models handle ambient temperatures from -20°C to 40°C, perfect for global industrial projects. Their compact design also suits space-constrained setups.5. What qualifications does a reputable manufacturer of slip ring motors need to have?

Look for producers that have undergone field testing and have earned ISO certification. Xicheng Electromechanical Equipment, a market leader in slip ring wrapped rotor motors, provides options for energy efficiency, customizable requirements (such as coatings for corrosive environments), and 12-month guarantees to help customers cut costs.

Best Selling Products

Related Blogs

Related Search

Add: Room 10715,building1,Heping Ginza,No.118 Heping Road,Beilin district,Xi'an city,shaanxi Province.

E-mail: xcmotors@163.com

TEL:+86 13571932715 / +86 15733661508

Whatsapp: +86 13571932715 / +86 15733661508