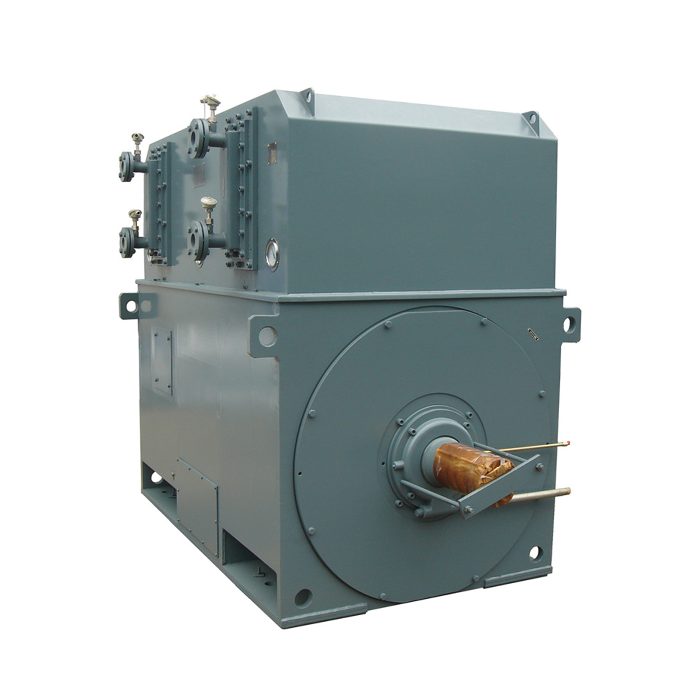

water cooled motors

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:220-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withGB/T 1032 and GB/T 13957 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

Water Cooled Motors - High Performance YKS Series

Looking for reliable water cooled motors that deliver exceptional performance in demanding industrial applications? Our YKS series product are engineered to provide superior cooling efficiency, reduced operating temperatures, and extended service life. With over 20 years of experience in power equipment solutions, XCMOTOR delivers high-voltage motors that meet the most stringent industrial requirements. These product feature advanced thermal management systems and robust construction for continuous operation in challenging environments.

Description

Our top range of high-voltage motors for demanding industrial applications is represented by the YKS series. Precision engineering and cutting-edge cooling technologies are combined in these motors to provide reliable performance under a variety of operating circumstances. To guarantee dependability and durability in your vital applications, every item is put through a thorough quality testing process.

Product Specifications

| Item | Specification |

|---|---|

| Series | YKS |

| Protection Level | IP54 (IP55 available for outdoor applications) |

| Voltage Range | 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%, 11000V±5% |

| Power Range | 220-6300 kW |

| Pole Options | 2-16 poles (speeds from 3000r/min to 375r/min) |

| Operating Temperature | -25℃ to 45℃ |

| Altitude | Up to 2000 meters |

| Bearings | SKF, NSK, FAG (customizable per requirements) |

Product Details

Our motors feature double-sided precision dynamic balancing achieving G1.0 level accuracy, resulting in vibration velocity ≤2.5mm/s. The innovative stator and rotor design incorporates skewed poles and unequal slot pitch configuration, reducing electromagnetic noise by 8-10dB compared to standard motors.

The cooling system utilizes low-noise axial flow fans that operate 15dB quieter than traditional cooling solutions. High-precision rolling bearings with sealed end caps and long-lasting grease maintain mechanical noise below 85dB under no-load conditions.

Production Process

Every motor undergoes comprehensive quality control procedures including:

- Precision machining of core components

- Multi-stage assembly with quality checkpoints

- Dynamic balancing and vibration testing

- Electrical performance validation

- Final inspection and certification

Our water cooled motors SAP factory management system ensures consistent quality throughout the production cycle while maintaining efficient delivery schedules.

Application Scenarios

These versatile motors excel in various industrial applications:

- Steel Industry: Rolling mills and heavy machinery drives

- Mining Operations: Main shaft hoists and crushers

- Petrochemical Plants: High-pressure compressors and pumps

- Power Generation: Cooling systems and circulating water pumps

- Manufacturing: Cutting machine tools and transportation machinery

Certifications

All products maintain comprehensive certifications including CCC, CE, ISO9001:2000, CRCC, CQC, ZDHY environmental management, China energy saving production certification, UL, and GOST certifications.

Why Choose XCMOTOR

With partnerships spanning over 30 motor manufacturers including ABB, Siemens, and Wolong, we provide:

- Genuine Components: Only parts from trusted brands

- Fast Delivery: Comprehensive logistics solutions

- 30-Day Returns: Risk-free purchase protection

- Dedicated Support: Seven-day customer service

- Customization: Solutions made to meet particular needs

To make sure your business operations are seamless, our skilled staff offers pre-sales consulting, technical assistance, and quick after-sales service.

Qualification Certification

Every motor satisfies stringent performance requirements thanks to our quality management system, which incorporates many international standards. Our accreditation status is upheld across all significant quality frameworks through routine audits and continuous improvement procedures.

FAQ

Q: What kind of upkeep are necessary for these motors?

A: Frequent examination of electrical connections, bearing lubrication, and cooling systems. Every item comes with a detailed maintenance schedule.

Q: Is it possible to alter the voltage specifications?

A:In accordance with your application's requirements, we may adjust dimensions and provide customisation for certain voltage requirements.

Q: What's the typical delivery time?

A: Standard models ship within 2-3 weeks. Custom configurations may require 4-6 weeks depending on specifications.

Q: Do you provide installation support?

A: Our technical team offers installation guidance and can provide on-site support for complex installations.

Contact Us

Our technical experts are available to assist you in choosing the best option for your use case.

Email: xcmotors@163.com

For comprehensive specs, cost details, or a technical consultation on water cooled motors, get in touch with us right now. Our goal is to deliver the power solutions that propel your business forward.

YOU MAY LIKE

VIEW MORE3.3 kv motor

VIEW MORE3.3 kv motor VIEW MOREYXKK series high voltage and high efficiency motor

VIEW MOREYXKK series high voltage and high efficiency motor VIEW MOREY(IP23) series high voltage asynchronous motor

VIEW MOREY(IP23) series high voltage asynchronous motor VIEW MOREac slip ring induction motor

VIEW MOREac slip ring induction motor VIEW MORE3 phase induction motor slip ring

VIEW MORE3 phase induction motor slip ring VIEW MORE6kv slip ring motor

VIEW MORE6kv slip ring motor VIEW MORE630 kw motor

VIEW MORE630 kw motor VIEW MOREWound Rotor Induction Motors

VIEW MOREWound Rotor Induction Motors