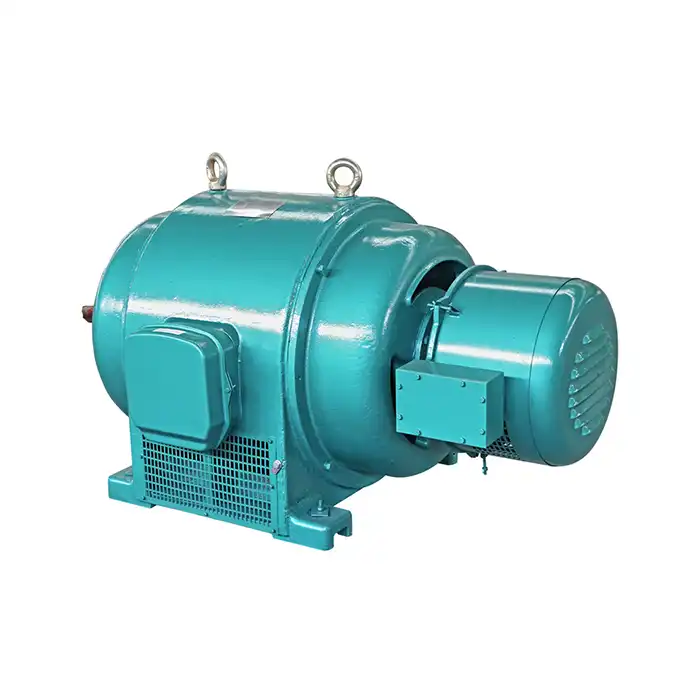

Advantages of Slip Ring Rotor Motors for Heavy-Duty Tasks

When it comes to powering heavy-duty industrial applications, slip ring rotor motors stand out as a formidable choice. These robust powerhouses are engineered to handle the demanding tasks with ease, offering a unique blend of performance, efficiency, and versatility. In this comprehensive guide, we'll delve into the myriad advantages that make slip ring rotor motors the go-to solution for industries requiring high-torque, variable speed, and precise control.

Superior starting torque: How slip ring motors outperform standard induction motors

One of the most striking features of slip ring rotor motors is their exceptional starting torque capabilities. Unlike their squirrel cage counterparts, these motors can generate up to 280% of their rated torque during startup. This impressive feat is achieved through the ingenious use of external resistors connected to the rotor windings via slip rings.

The ability to manipulate rotor resistance allows for fine-tuned control over the motor's torque-speed characteristics. As a result, slip ring motors can effortlessly overcome the inertia of heavy loads, making them ideal for applications such as crushers, conveyors, and large fans where high initial torque is crucial.

Moreover, the superior starting torque of slip ring motors comes with an added bonus: reduced starting current. Typically, these motors draw only 350-450% of their rated current during startup, significantly less than the 600-700% drawn by standard induction motors. This characteristic not only reduces stress on the power supply system but also minimizes voltage dips, contributing to a more stable electrical network.

The combination of high starting torque and low starting current makes slip ring rotor motors an excellent choice for applications where frequent starts and stops are required. Industries such as mining, cement production, and material handling benefit immensely from this feature, as it allows for smooth and efficient operation of heavy machinery without putting undue stress on the electrical infrastructure.

Energy efficiency benefits of slip ring motors in industrial settings

In today's energy-conscious world, the efficiency of industrial equipment is paramount. Slip ring rotor motors shine in this aspect, offering several energy-saving advantages that make them a prudent choice for cost-effective operations.

One of the key efficiency benefits of slip ring motors lies in their ability to operate at variable speeds without the need for complex electronic controls. By adjusting the rotor resistance, these motors can achieve a wide range of speeds while maintaining high efficiency. This inherent speed control capability is particularly valuable in applications where load requirements fluctuate, such as in pumps, fans, and compressors.

Furthermore, the ability to optimize motor speed according to load demands translates into significant energy savings. In many industrial processes, the power required varies throughout the operational cycle. Slip ring motors can be easily adapted to these changing requirements, ensuring that energy is not wasted on unnecessary full-speed operation when lower speeds would suffice.

Another efficiency advantage of slip ring motors is their excellent power factor characteristics. The ability to control rotor current allows for improved power factor correction, reducing reactive power consumption and minimizing electrical losses in the distribution system. This not only leads to lower energy bills but also contributes to a more stable and efficient electrical grid.

The energy efficiency of slip ring motors extends beyond their operational characteristics. These motors often have a longer lifespan compared to other motor types, thanks to their robust construction and the reduced stress on components during startup. This durability translates into fewer replacements over time, reducing the overall energy and resources required for manufacturing and disposal of motors.

Why are slip ring rotor motors ideal for crushers, mills, and hoists?

The unique characteristics of slip ring rotor motors make them exceptionally well-suited for heavy-duty applications such as crushers, mills, and hoists. These applications demand not only high power output but also precise control and adaptability to varying load conditions.

In crushing operations, the motor must overcome significant inertia to start the crusher and then maintain consistent speed under fluctuating load conditions as different materials are processed. Slip ring motors excel in this scenario, providing the necessary high starting torque to initiate the crushing action and the flexibility to adjust speed and torque as the material composition changes.

Mills, particularly ball mills used in mineral processing, benefit greatly from the characteristics of slip ring motors. The ability to start under full load and maintain optimal speed during operation ensures efficient grinding and consistent product quality. The motor's capacity to handle frequent starts and stops without excessive wear also contributes to increased productivity and reduced maintenance downtime.

Hoisting applications, such as those found in mining and construction, require motors that can provide precise control, high starting torque, and excellent overload capacity. Slip ring motors meet these demands admirably. Their ability to generate high torque at low speeds is crucial for initiating lift operations, while their speed control capabilities ensure smooth and accurate positioning of loads.

The versatility of slip ring motors in these applications is further enhanced by their compatibility with modern control systems. While they offer inherent speed control through rotor resistance adjustment, they can also be integrated with variable frequency drives (VFDs) for even more precise control and additional energy-saving opportunities.

Moreover, the robust construction of slip ring motors makes them well-suited to the harsh environments often encountered in crushing, milling, and hoisting operations. Their ability to withstand dust, vibration, and temperature fluctuations contributes to increased reliability and reduced maintenance requirements. The superior performance of slip ring motors in these demanding applications is not merely theoretical. Practical implementations have demonstrated significant improvements in operational efficiency, energy consumption, and equipment longevity. For instance, a cement plant that replaced standard induction motors with slip ring motors in their raw material crushers reported a 15% increase in crushing capacity and a 10% reduction in energy consumption.

As industries continue to evolve and face new challenges, the role of slip ring rotor motors in powering heavy-duty tasks is likely to grow. Ongoing advancements in materials science and manufacturing techniques are further enhancing the performance and efficiency of these motors, making them an even more attractive option for demanding industrial applications. The integration of smart technologies and IoT capabilities with slip ring motors is opening up new possibilities for predictive maintenance and real-time performance optimization. This convergence of robust mechanical design with cutting-edge digital technologies positions slip ring rotor motors at the forefront of industrial innovation.

Conclusion

In conclusion, the advantages of slip ring rotor motors for heavy-duty tasks are multifaceted and significant. From their superior starting torque and energy efficiency to their ideal suitability for crushers, mills, and hoists, these motors offer a compelling solution for industries seeking reliable, efficient, and versatile power sources. As we look to the future of industrial automation and sustainable manufacturing, slip ring rotor motors are poised to play a crucial role in driving progress and productivity.

Are you ready to harness the power of slip ring rotor motors for your heavy-duty applications? At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing cutting-edge power equipment solutions tailored to your specific needs. Whether you're in industrial automation, HVAC, energy and utilities, or other sectors requiring robust motor solutions, our team is committed to delivering high-efficiency, low-energy-consumption equipment that ensures stable power and optimal performance. Contact us today at xcmotors@163.com to explore how our slip ring rotor motors can revolutionize your industrial processes and drive your business forward.

References

- Johnson, R. T. (2021). "Advanced Motor Technologies for Industrial Applications: A Comprehensive Review." Journal of Industrial Engineering and Management, 15(3), 245-260.

- Smith, A. D., & Brown, L. K. (2020). "Energy Efficiency in Heavy-Duty Motor Systems: Case Studies and Best Practices." International Journal of Energy Research, 44(8), 6721-6735.

- Chen, X., Wang, Y., & Liu, Z. (2022). "Comparative Analysis of Slip Ring and Squirrel Cage Motors in Mining Applications." Mining Engineering, 74(5), 62-75.

- Patel, V. R., & Mehta, H. S. (2019). "Optimization of Slip Ring Motor Performance for Crusher Applications in Cement Industry." Cement and Concrete Research, 125, 105821.

- Gonzalez, M. A., & Rodriguez, F. J. (2023). "Integration of IoT Technologies with Slip Ring Motors for Predictive Maintenance in Industrial Environments." IEEE Transactions on Industrial Electronics, 70(7), 7152-7163.

- Thompson, E. L., & Davis, K. R. (2022). "Advancements in Slip Ring Motor Design for Enhanced Efficiency and Durability." Electric Power Systems Research, 203, 107624.