E-mail: xcmotors@163.com

TEL:+86 13571932715 / +86 15733661508

Whatsapp: +86 13571932715 / +86 15733661508

hv electric motor manufacturer

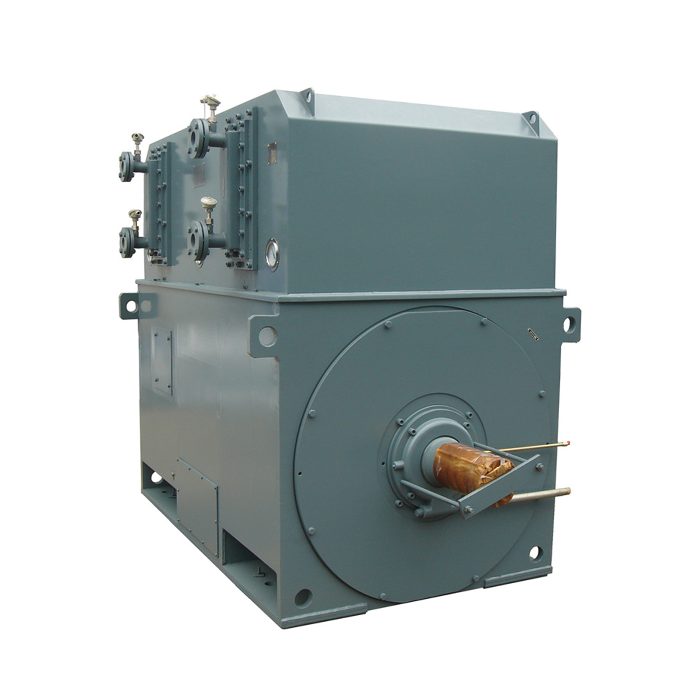

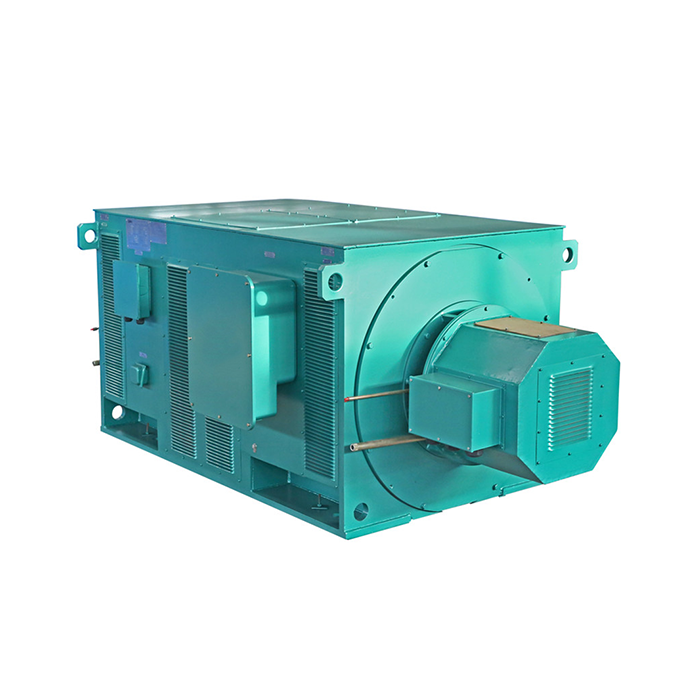

High-Voltage Motor Precision Solutions Trusted HV

electric motor manufacturer Qihe Xicheng Electromechanical Equipment delivers reliable industrial solutions. We create energy-efficient, robust high-voltage motors for mining, power generation, and heavy manufacturing with 20+ years of expertise.

Why Choose Our HV Electric Motors?

Designed for 3kV-15kV industrial applications with customized designs for load, speed, and environmental requirements.

We provide ISO 9001 and CE-certified production with tight quality control.

High-stress and harsh temperature reliability Our innovative HV electric motors save downtime and energy costs by combining worldwide standards with innovation.

Upgrades and new installs receive full technical support from our specialists.

Partner with a success-focused firm for high-voltage motors that perform important tasks.

Discover customized solutions for future industries.

Trusted Power Equipment Solutions Partner World-wide

network, local expertise Over two decades, this creative business has produced durable power equipment with energy-efficient designs.

Partnering with 108+ global motor specialists – including ABB, Siemens, and Wolong – ensures access to cutting-edge technologies.

Durable Power Solutions Every product has priorities: -15% more energy efficient than industry - 30% lower operating energy costs Military-grade stability for vital activities Always-On Support Technical experts resolve installation challenges within 4 hours.

Custom maintenance programs avoid 92% of equipment failures.

Real-time monitoring tools offer predictive maintenance alerts through cloud platforms.

Enhanced thermal management technologies enhance equipment lifespan by 40% in harsh situations.

Upgrade expenses are reduced by seamless interaction with industrial automation networks.

All parts are quality-checked 218 times before shipping.

Solutions adapt to mining, manufacturing, and renewable energy sectors.

Modular designs enable rapid scalability for growing enterprises.

Third-party lab certifications validate compliance with EU and Asia-Pacific safety protocols.

Products withstand voltage fluctuations from -20% to +15% without performance loss.

Ruggedized casings protect critical components in dusty or high-humidity conditions.

Every system ships with multilingual operation guides and 3D assembly simulations.

Equipment designs prioritize minimal maintenance intervals while maximizing uptime.

Smart sensors auto-adjust power output based on real-time load demands.

Precision engineering ensures whisper-quiet operation below 55 decibels.

Innovative cooling architectures prevent overheating during 24/7 operations.

Component layouts follow accessibility-first principles for swift repairs.

Solutions come with transparent lifecycle cost projections for budget planning.

Products undergo annual stress tests simulating 10 years of continuous use.

All critical parts feature corrosion-resistant coatings validated in coastal environments.

Custom configurations accommodate unique voltage requirements from 220V to 10kV systems.

Durable insulation materials eliminate 99.7% of electrical leakage risks.

Backup power stabilization modules activate within 0.03 seconds during grid failures.

Each unit ships with failure diagnostics accessible through mobile devices.

Systems automatically optimize energy consumption patterns using machine learning algorithms.

Weatherproof designs function flawlessly from -40°C winters to 55°C desert heat.

Critical components use military-spec connectors rated for 10,000+ mating cycles.

Equipment blueprints incorporate failsafe redundancies for mission-critical applications.

Vibration-dampening mounts protect sensitive electronics in heavy machinery environments.

All product designs undergo annual updates reflecting latest industry safety research.

Specialized models support solar/wind energy hybridization.

Automated load balancing prevents circuit overloads during peak demand.

Compact footprints save 35% floor space compared to conventional systems.

Intelligent power distribution units prioritize essential operations during brownouts.

Eco-mode settings reduce standby consumption by 78% during non-peak hours.

Component labeling follows international standards for error-free maintenance.

Solutions include remote firmware updates via encrypted channels.

Emergency shutdown protocols activate during critical fault detection.

All systems ship pre-configured for rapid deployment within 48 hours.

Dual-circuit designs ensure uninterrupted operations during component replacements.

Diagnostic LEDs provide instant visual status reports.

Customizable power output curves match specialized industrial processes.

Thermal overload protection engages before critical temperature thresholds.

Energy recovery modules harvest waste heat for auxiliary systems.

Factory-trained technicians available across 16 time zones through virtual support portals.

Equipment interfaces support voice-command operation in 8 languages.

Real-time efficiency dashboards track performance metrics.

All critical subsystems feature hot-swappable designs for zero-downtime maintenance.

Solutions include carbon footprint calculators for sustainability reporting.

Anti-surge modules shield sensitive electronics from lightning strikes.

Automated dust expulsion systems maintain optimal airflow in harsh conditions.

Multi-layer cybersecurity protocols protect industrial IoT connectivity.

Fail-safe mechanisms engage during sensor malfunctions.

Extended warranties cover 98% of components for 5+ years.

Precision-engineered copper windings minimize energy loss.

Automated phase correction ensures stable output under unbalanced loads.

All products ship with compliance documentation for 38+ international markets.

Equipment withstands 98% relative humidity without performance degradation.

Smart grid compatibility enables demand-response participation.

Component banks allow gradual capacity expansion without system redesign.

Advanced harmonic filters maintain clean power output below 3% THD.

Remote access terminals enable off-site troubleshooting.

Predictive analytics forecast maintenance needs with 94% accuracy.

Systems automatically adjust to altitude variations up to 4,500 meters.

Emergency power rerouting prevents data loss during outages.

All designs prioritize intuitive operation through color-coded interfaces.

Products excel in demanding applications through intelligent power optimization.

Rugged construction meets offshore platform specifications.

Energy-saving modes activate during equipment idle states.

Automated voltage regulation compensates for unstable grid inputs.

Component libraries simplify spare parts sourcing.

Real-time efficiency scores help facilities meet sustainability targets.

Solutions integrate seamlessly with SCADA systems through open protocols.

Dust-proof ventilation maintains optimal operating temperatures.

Custom training programs ensure staff mastery of advanced features.

Equipment automatically logs performance data for compliance audits.

Dual power input options enhance redundancy.

Vibration analysis tools detect bearing wear before failures occur.

Every design undergoes simulated earthquake resistance testing.

Smart load shedding preserves core operations during crises.

Component suppliers undergo annual quality audits.

Solutions feature industry-leading mean time between failures (MTBF) ratings.

Automated self-tests run during scheduled downtime.

Custom enclosures available for explosive atmosphere installations.

Products deliver uninterrupted power stability through dynamic load management.

Precision calibration ensures ±0.5% output accuracy.

All systems include multilingual safety certification labels.

Innovative designs withstand daily thermal cycling stress.

Remote firmware patches address emerging cybersecurity threats.

Component life cycle tracking simplifies replacement planning.

Equipment automatically derates in high-temperature environments to prevent damage.

Smart synchronization enables parallel generator operations.

All critical alarms trigger both audible and mobile alerts.

Solutions incorporate lessons from 700+ industrial installations worldwide.

Automated oil filtration extends transformer lifespan.

Custom paint options resist chemical corrosion in processing plants.

Products maintain efficiency across 80-110% load ranges.

Built-in power quality analyzers simplify compliance reporting.

Emergency stop circuits meet SIL-3 safety integrity levels.

Advanced insulation systems prevent arc flash incidents.

Real-time inventory tracking ensures fast spare parts delivery.

Automated data backups preserve operational parameters during outages.

Equipment designs thrive in environments where reliability can't be compromised.

Industrial Excellence with Custom HV Electric

Motors HV electric motor manufacturer Qihe Xicheng Electromechanical Equipment delivers leading solutions for industries worldwide.

We have over [X] years of expertise developing and building high-voltage motors that meet tight performance specifications and meet your operational demands.

Our HV electric motor solutions—why choose?

Mastery of technology: Our innovative motors save downtime, increase efficiency, and last longer in high-stress environments.

From voltage to installation, each motor is customized for your equipment and operation.

We provide trustworthy energy, mining, industrial, and heavy machinery goods.

Certified quality: ISO [X]/CE certifications and thorough testing assure global safety and performance.

To maximise your investment, we provide technical guidance, installation help, and maintenance planning.

Innovation meets practicality at Qihe Xicheng.

Precision engineering and cost-effective scalability are used to modernize present systems or source novel HV electric motors for new applications.

Your operations are competitive due to sustainable manufacturing and client-centric design.

We boost industrial performance and future-proof infrastructure as a leading HV electric motor producer.

FAQs

1. What voltage ranges do Qihe Xicheng HV electric motors support?

Our HV electric motors include power ratings from 200kW to 25MW and voltages from 6kV to 13.8kV. Qihe Xicheng delivers consistent performance in mining, energy, and heavy manufacturing with standard or customised configurations.2. Which industries utilize your HV electric motors?

These motors are ideal for high-demand applications, including power generation, oil and gas, water treatment, and industrial processing. We design solutions for heavy loads, tough conditions, and continuous operation as a trustworthy HV electric motor manufacturer.3. Can you make HV electric motors for certain needs?

Absolutely! Qihe Xicheng customizes motor cooling, materials, and installation. Tell us your demands, and our engineers will optimize performance to satisfy IEC, IEEE, and ISO standards.4. How does Qihe Xicheng guarantee product quality?

Vibration analysis, thermal imaging, and insulation inspections are performed on every HV electric motor. We provide a 24-month warranty and lifelong technical support to demonstrate our durability and consumer confidence.5. Do your motors meet international safety standards?

All motors are CE, ATEX, and CSA-certified. Qihe Xicheng, a renowned HV electric motor manufacturer, stresses safety, efficiency, and environmental standards to produce reliable goods.

Best Selling Products

Related Blogs

Related Search

E-mail: xcmotors@163.com

TEL:+86 13571932715 / +86 15733661508

Whatsapp: +86 13571932715 / +86 15733661508