E-mail: xcmotors@163.com

TEL:+86 13571932715 / +86 15733661508

Whatsapp: +86 13571932715 / +86 15733661508

motors for pulp mills manufacturer

Trustworthy Pulp Mill Motors: Expertise A

reputable manufacturer of industrial motors for pulp processing, Qihe Xicheng Electromechanical Equipment meets pulp mills' specialized needs with unrivaled dependability and energy efficiency.

With decades of expertise, we offer robust pulp mill motor solutions that survive rigorous working conditions and minimize downtime.

We work together with clients to design custom-engineered motors that meet your manufacturing requirements.

Every motor shows our dedication to technological innovation, from sturdy designs for heavy-duty paper production machinery to performance-optimizing cooling systems.

Globally recognized certifications demonstrate our strict quality standards, ensuring long-term operational stability.

Our industry-specific experience provides seamless integration and efficiency increases whether updating systems or purchasing new gear.

Precision engineering and flexible solutions make Qihe Xicheng a partner for mills seeking durability, efficiency, and scalability.

Their motors are designed for harsh situations, keeping your operations ahead with reliable technology.

Modern Industry Power Options 20+ Years

of Experience Shaanxi Qihe Xicheng Electromechanical Equipment Co. , Ltd.

makes reliable power equipment.

Over two decades of experience have improved the company's technological skills for industry.

Reliable Global Partnerships Cooperate to succeed.

ABB, Siemens, Wolong, and NEC are among the 67+ motor manufacturers it works with.

These collaborations provide cutting-edge technologies and designs.

Efficient Energy Use All solutions prioritize energy efficiency and low cost.

Products produce stable electricity, reducing downtime and increasing business productivity.

Smooth Tech Support Customers receive full assistance from pre-sales to post-installation.

Fast replies and expert guidance ease complicated challenges.

Sustainable Industrial Growth Innovative engineering and eco-friendly methods help companies achieve long-term operational and environmental goals.

Their innovations increase operations while conserving energy and being green.

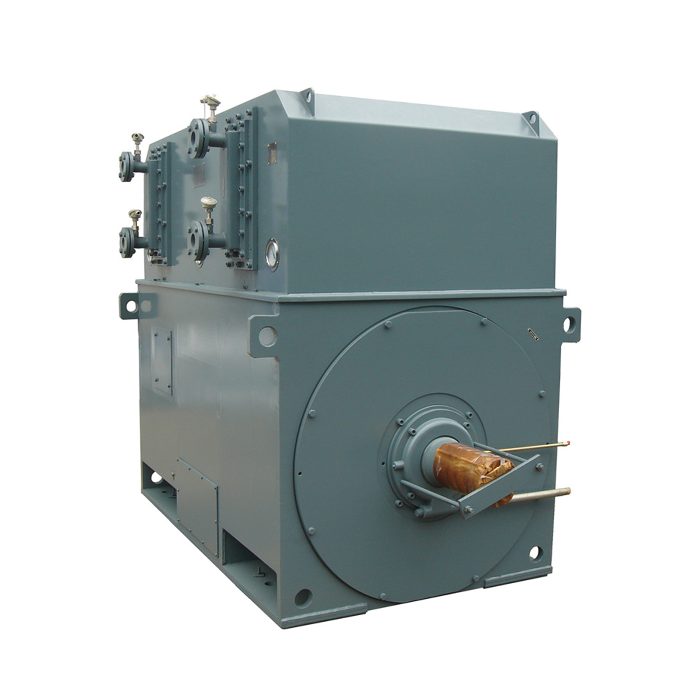

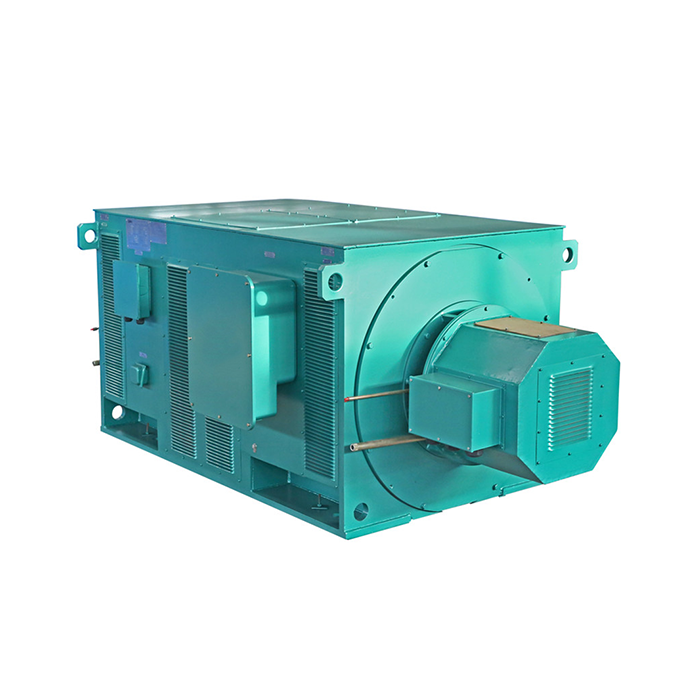

Precision-built motors power pulp mills For

dependable pulp mill motors, Qihe Xicheng Electromechanical Equipment is a top producer. We create motors for high-torque refining and continuous agitation in the pulp and paper industries.

Energy efficiency lowers operational expenses, while tough design withstands humid, harsh situations.

We combine superior engineering with unique skills as a leading pulp mill motor manufacturer.

Our motors meet load and space requirements for refiners, agitators, pumps, and other pulp processing equipment.

Premium materials including corrosion-resistant metals provide long-term performance.

Our technical competence distinguishes us.

Our team collaborates with clients to improve motor designs for individual operations and integrate smart controls for automation.

From downtime reduction to energy savings, every solution promotes long-term value.

All motors meet ISO 9001 certifications and undergo rigorous testing to ensure compliance with global standards.

Beyond delivery, we provide dedicated after-sales support, including maintenance guidance and rapid spare-part sourcing.

Qihe Xicheng provides reliable, efficient, and adjustable motor systems for mills that operate production lines smoothly.

FAQs

1. Why is Qihe Xicheng a trusted pulp mill motors manufacturer?

Our tough pulp mill motors provide IP55/56 protection, 200-5000 kW power, and corrosion-resistant materials. Our specialist manufacturing uses energy-efficient designs (IE3/IE4 standards) to save operational expenses and provide 24/7 dependability.2. How do your motors withstand high pulp processing?

Our motors can handle continuous grinding, refining, and pumping loads due to their high torque and strengthened bearings. Despite extreme humidity, custom cooling systems prevent mill overheating. Maintenance checkups (3,000-hour lubrication) enhance motor life.3. Can motors be customized for pulp mill layouts?

We adapt frame sizes, shaft heights, and mounting styles (flange or foot-mounted) to restricted areas or old equipment. Variable speed drives and explosion-proof designs are available for hazardous areas.4. What energy-saving features do your motors have?

The latest copper rotor technology and low-friction seals save 15% of energy. Our motors have sophisticated sensors for real-time efficiency monitoring, enabling mills reach sustainability targets without losing performance.5. Can pulp mill motors be replaced quickly?

With a stocked inventory and flexible production lines, we ship standard models in 7-10 days. Emergency service comprises on-site troubleshooting and priority manufacture to reduce essential operating downtime.

Best Selling Products

Related Blogs

Related Search

E-mail: xcmotors@163.com

TEL:+86 13571932715 / +86 15733661508

Whatsapp: +86 13571932715 / +86 15733661508