To find reliable 6600V motor makers, you need to carefully look at their technical skills, quality standards, and customer service. Some of the biggest companies in China make a wide range of high-voltage motors that can handle power levels from 200kW to 6300kW and meet international safety standards (IP54). These experts in 6600v motors make reliable tools for automating factories, making electricity, and controlling processes in a wide range of fields, such as mining, petrochemicals, and building up green energy systems.

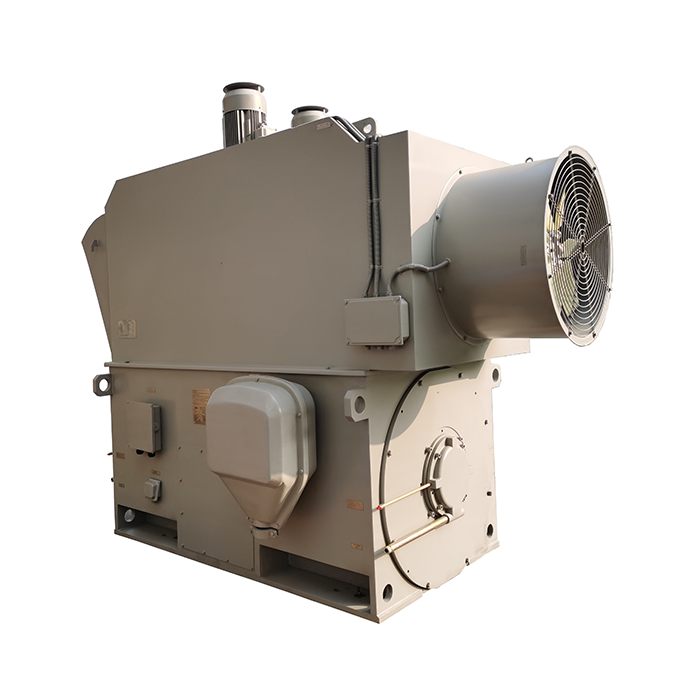

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

China's Manufacturing Excellence in High Voltage Motor Production

With its modern technology and low-cost production methods, China has become the world leader in making high voltage motors. A lot of money is spent on research and development in the country's electrical machinery sector. This leads to more advanced manufacturing ecosystems that support a wide range of commercial uses.

Infrastructure for advanced manufacturing

The factories that make these goods in China are very advanced, with automatic winding systems and vacuum pressure impregnation systems. These technologies make sure that the protection is better and that the motor lasts longer. These days, modern factories use precision machining centers to make parts with very tight specs. This helps the motor work better and last longer. Using ideas from Industry 4.0 has changed the way production lines work, letting quality be checked in real time and maintenance planned ahead of time. Manufacturers use detailed testing methods to check the electrical properties, mechanical performance, and thermal behavior in settings that are similar to real-life situations.

Innovation and technical know-how

Chinese engineers have become experts at optimizing motor designs with the goal of making them more efficient and quieter. Advanced electromagnetic simulation software lets you do accurate estimates for managing heat and magnetic flux. 6600V motors that work consistently in harsh industrial settings are made possible by this level of technical skill. Manufacturers and universities working together on research projects has sped up progress in materials science, resulting in better copper wire designs and better bearing technologies. These improvements have led to motors that use less energy and need less upkeep.

Important things to look for in a reliable automaker

There are many things to think about when picking the right company that will affect your long-term business success. A thorough evaluation makes sure that partnerships offer value beyond the initial purchase.

Evaluation of Technical Skills

Check to see if manufacturers can change the specs of motors to fit special needs. Suppliers who can work with voltages between 3000V and 11000V can be trusted. There should be performance curves, thermal characteristics, and efficiency scores in the technical literature. Check to see how much experience the motor maker has with fans, water pumps, compressors, and other heavy machinery. Diverse application knowledge shows that you understand operational problems and the needs for solutions.

Systems for managing quality

Check out how the maker tests and controls quality. Reliable companies can test electrical efficiency, look at vibrations, and keep an eye on temperatures. Raw materials should be checked, processes should be watched while they're happening, and finished things should be checked. Check out the documentation and traceability tools to get a full picture of the manufacturing process. Quality management makes products more reliable by controlling processes statistically and always making them better.

Flexibility and the ability to make things

Check the manufacturing capacity to make sure deliveries happen on time without lowering the standard. Manufacturers you can trust have enough production ability to meet delivery dates and deal with orders of different sizes. Operational maturity shows that you can adapt to meet pressing needs or make changes to the design. Look at how you handle your inventory and how you connect with component suppliers. Strong supply networks keep materials at the same quality and cut down on production delays.

Infrastructure for Service and Support

After you buy something, make sure you can get technical help, upkeep tips, and replacement parts. With local help, comprehensive service networks cut down on downtime and operational costs. Manufacturers should take care of installation, setup, and training for operators.Check to see what the motor component and performance promises are covered by the warranty. Longer guarantees show that the company that made the product trusts its quality and dependability.

Critical Certification Requirements and Standards Compliance

International certifications show that a company meets standards for safety, efficiency, and the environment. These certifications make sure that 6600V motors meet world standards for a wide range of industrial uses.

Meeting International Standards

Check that the rotating electrical tools are in line with the IEC 60034 standards. This complete standard includes rules for safety, ratings of performance, and ways to test things. Manufacturers should give test results that show they follow the relevant parts of the standard. When something has a CE mark on it, it means that it meets European safety, health, and environmental standards. This certification lets you sell your products in all EU countries and shows that you are committed to meeting foreign quality standards.

Certifications for Quality Systems

ISO 9001 approval proves that a quality management system is being used to make sure that product quality is always high and customers are happy. This standard calls for methods to be written down, regular audits, and ways to keep getting better. Getting an environmental management certification like ISO 14001 shows that you are committed to making your business more environmentally friendly. As environmental duty becomes more important in business, these certifications become more important.

Certifications for Specific Industries

With explosion-proof licenses, motors can work in dangerous places like petrochemical and mining sites. To make sure they work safely, these approvals need specific design features and strict testing methods. Energy economy certifications back up claims about motor performance and help businesses follow the rules in many markets. In energy-conscious settings, these certifications often affect the buying choice.

Strategic Approaches to OEM and ODM Partnerships

Successful OEM and ODM collaborations require clear communication, detailed specifications, and mutual understanding of project objectives. Strategic partnerships can provide competitive advantages and customized solutions.

Partnership Structure Development

Clarify partnership goals, including technical requirements, delivery schedules, and quality. Partnerships succeed with comprehensive agreements on roles, IP rights, and performance indicators. Communication mechanisms should assure project updates and issue resolution. Meetings and progress reports keep projects on track and uncover issues early.

Technical Collaboration Management

Provide detailed technical specifications for accurate quotes and realistic delivery dates. Detailed specifications prevent misunderstandings and ensure product application compliance. Design evaluations and validation should involve both firms' technical teams. Performance, affordability, and manufacturability are often optimized by collaborative engineering.

Intellectual Property Protection

Protect proprietary information and design specifications via confidentiality agreements. Clear IP terms allow constructive collaboration and reduce disputes. Consider trademark and patent implications for customized items to protect collaboration-developed designs and inventions.

Effective MOQ and Pricing Negotiation Strategies

Understanding minimum order quantities and pricing structures enables effective procurement planning and cost optimization. Strategic negotiation approaches can result in favorable terms and long-term value.

Volume-Based Pricing Analysis

Determine appropriate order amounts by analyzing pricing structures across volume levels. Manufacturers offer big savings for larger volumes, but optimal numbers balance unit costs and inventory carrying costs. Annual volume commitments may qualify for preferential pricing and procurement flexibility. Some manufacturers provide volume discounts for repeat business.

Payment Terms and Conditions

Balance supplier requirements and cash flow when negotiating payment arrangements. Flexible payment models can improve operations and supplier relations. Consider manufacturer financing for larger projects. Suppliers offer equipment finance or longer payment terms to boost project profitability.

Total Cost of Ownership Evaluation

Consider shipping, installation, and long-term maintenance costs beyond the purchase price. Premium motors may justify higher prices due to lower operational expenses and longer service life. Compare supplier warranties and servicing prices. Comprehensive warranties can greatly affect motor service life ownership costs.

Comprehensive Factory Audit and Quality Assurance Guidelines

Factory audits provide valuable insights into manufacturing capabilities, quality systems, and operational practices. Systematic evaluation approaches ensure comprehensive supplier assessment.

Manufacturing Process Evaluation

Examine production workflows and quality control checkpoints throughout the manufacturing process. Effective processes include incoming material inspection, in-process monitoring, and final product testing. Evaluate equipment condition and maintenance practices that impact product quality and delivery reliability. Well-maintained facilities indicate commitment to operational excellence and consistent output quality.

Quality System Assessment

Review quality management documentation including procedures, work instructions, and testing protocols. Comprehensive quality systems provide confidence in consistent product quality and regulatory compliance. Examine calibration programs for testing equipment and measurement instruments. Regular calibration ensures accurate testing results and validates product specifications.

Workforce Evaluation

Assess technical competence and training programs that maintain workforce skills. Qualified personnel contribute significantly to product quality and manufacturing consistency. Examine safety practices and workplace conditions that indicate overall operational maturity. Safe working environments often correlate with attention to detail and quality consciousness.

Conclusion

Selecting the right 6600V motor manufacturer requires systematic evaluation of technical capabilities, quality systems, and service support. Chinese manufacturers offer compelling combinations of advanced technology, competitive pricing, and comprehensive service networks. Success depends on thorough supplier assessment, clear communication, and strategic partnership development. Focus on manufacturers who demonstrate proven track records, appropriate certifications, and commitment to continuous improvement. Effective supplier selection processes consider total cost of ownership rather than initial price alone, ensuring long-term value and operational success.

Frequently Asked Questions

Q1: What voltage tolerances should I expect from quality 6600V motors?

A: Quality manufacturers typically provide motors with voltage tolerances of ±5% for 6600V systems. This tolerance ensures stable operation across normal power system variations while maintaining optimal efficiency and performance characteristics.

Q2: How long does custom motor manufacturing typically take?

A: Standard lead times range from 8-12 weeks depending on specifications and quantity. Custom designs may require additional engineering time, while standard configurations often ship within shorter timeframes. Manufacturers should provide realistic delivery schedules during quotation processes.

Q3: What insulation classes are available for high voltage applications?

A: Most manufacturers offer Class F insulation as standard, with Class H available as an upgrade option. Class H insulation provides higher temperature tolerance and extended service life in demanding applications. Insulation selection should match application temperature requirements and environmental conditions.

Partner with XCMOTOR for Premium High Voltage Motor Solutions

XCMOTOR is your reliable high voltage motor provider, providing 6600v motor solutions for demanding industrial applications. Our 200kW to 6300kW product range has IP54 protection and Class F insulation systems and 3000V to 11000V voltage options. We use premium SKF, NSK, and FAG bearings and precision-machined components for best performance and longevity. Our motors perform well in fans, pumps, compressors, and industrial machinery in manufacturing, energy, and process control. Advanced manufacturing methods including automated winding and vacuum pressure impregnation provide quality and reliability. Every motor is tested to meet international standards and work well.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides complete power equipment solutions with fast delivery, 30-day return policies, and dedicated technical support. Our experienced team offers global installation, commissioning, and training services to ensure successful project implementation. Ready to discuss your 6600v motor manufacturer requirements? Contact us at xcmotors@163.com or visit motorxc.com for detailed specifications and technical support.

References

1. International Electrotechnical Commission. "Rotating Electrical Machines - Part 1: Rating and Performance." IEC 60034-1:2017 Standard.

2. Chen, Wei and Liu, Ming. "Advanced Manufacturing Techniques in High Voltage Motor Production." Journal of Electrical Engineering and Manufacturing, Vol. 45, 2023.

3. Zhang, Li et al. "Quality Assurance Systems in Chinese Electrical Equipment Manufacturing." Industrial Quality Management Review, Issue 8, 2024.

4. Wang, Hua. "Sustainable Practices in Motor Manufacturing: A Comprehensive Analysis." Green Technology and Manufacturing Quarterly, Summer 2024.

5. Industrial Motor Manufacturing Association. "Global Market Analysis: High Voltage Motor Trends and Projections 2024-2025." Annual Industry Report.

6. Thompson, Robert and Kumar, Raj. "Supplier Selection Criteria for Industrial Equipment Procurement." Supply Chain Management Today, March 2024.