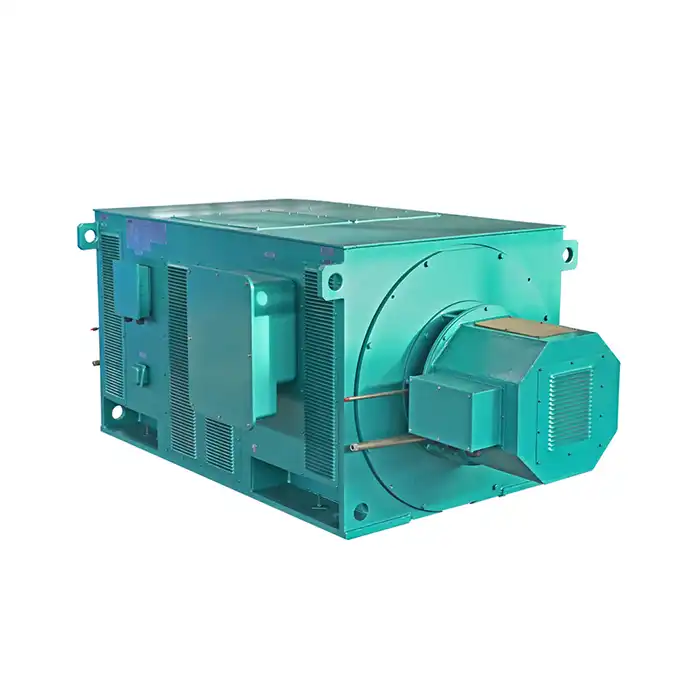

Detailed 6kV Slip Ring Motor Specifications You Need to Know

When it comes to powering heavy-duty industrial applications, 6kV slip ring motors are often the go-to choice for many engineers and plant managers. These robust motors are designed to handle high-voltage operations while providing exceptional starting torque and speed control. In this comprehensive guide, we'll dive into the essential specifications you need to know about 6kV slip ring motors, helping you make informed decisions for your industrial power needs.

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Key Electrical Parameters for 6kV Slip Ring Motors

Understanding the electrical parameters of 6kV slip ring motors is crucial for selecting the right motor for your application. Let's break down some of the most important specifications:

Voltage Range

6kV slip ring motors typically operate within a voltage range of 6000V ±5%. This means the motor can effectively function between 5700V and 6300V. Some manufacturers also offer models that can operate at 3000V ±5%, 3300V ±5%, 6600V ±5%, 10000V ±5%, and 11000V ±5%, providing flexibility for various industrial power systems.

Power Range

The power output of 6kV slip ring motors can vary significantly, typically ranging from 200kW to 5600kW. This wide range allows for applications in various industries, from small-scale operations to large industrial complexes.

Frequency

Most 6kV slip ring motors are designed to operate at either 50Hz or 60Hz, depending on the regional power grid specifications. It's essential to choose a motor that matches your local power supply frequency to ensure optimal performance.

Efficiency

Modern 6kV slip ring motors boast high efficiency ratings, often reaching up to 97%. This high efficiency translates to lower energy costs and reduced environmental impact over the motor's lifetime.

Power Factor

The power factor of 6kV slip ring motors typically ranges from 0.8 to 0.9. A higher power factor indicates more efficient use of electrical power, reducing strain on the power supply system.

What Protection Class (IP Rating) Do You Need?

The IP (Ingress Protection) rating is a crucial specification that indicates how well a motor is protected against solid objects and liquids. For 6kV slip ring motors, the standard protection class is often IP23.

Understanding IP23

In the IP23 rating:

- The first digit (2) indicates protection against solid objects larger than 12.5mm.

- The second digit (3) signifies protection against water spraying at an angle up to 60 degrees from vertical.

This level of protection is suitable for many industrial applications where the motor is not exposed to heavy dust or direct water spray. However, for more demanding environments, motors with higher IP ratings may be necessary.

Considerations for Higher IP Ratings

In some cases, you might need a motor with a higher IP rating:

- IP54: Offers protection against dust and water splashes from all directions.

- IP55: Provides protection against dust and low-pressure water jets.

- IP65: Ensures total protection against dust and low-pressure water jets.

When selecting the appropriate IP rating, consider the specific environmental conditions in which the motor will operate. Factors such as dust levels, humidity, and potential exposure to water should all be taken into account.

Understanding the Power Range (200kW-5000kW)

The power range of 6kV slip ring motors is vast, typically spanning from 200kW to 5000kW. This wide range allows these motors to be utilized in a variety of industrial applications, each with its own power requirements.

Low-End Power Range (200kW-1000kW)

Motors in this range are often used in:

- Small to medium-sized pumps and compressors

- Conveyor systems in mining operations

- Small mills and crushers in the cement industry

These motors provide a balance between power and efficiency, making them suitable for applications that require significant starting torque but don't demand extremely high continuous power output.

Mid-Range Power (1000kW-3000kW)

This power range is commonly found in:

- Large industrial pumps and fans

- Medium-sized compressors in the oil and gas industry

- Rolling mills in the steel industry

Motors in this range offer substantial power output while maintaining good efficiency, making them ideal for demanding industrial processes that require continuous operation.

High-End Power Range (3000kW-5000kW)

The highest power 6kV slip ring motors are typically used in:

- Large compressors in petrochemical plants

- Heavy-duty mills and crushers in mining operations

- High-capacity pumps in water treatment facilities

These motors are designed for the most demanding industrial applications, providing immense power output and the ability to handle extreme loads.

Factors Influencing Power Selection

When choosing the appropriate power rating for your 6kV slip ring motor, consider the following factors:

- Load characteristics: Consider both starting and running loads.

- Duty cycle: Determine if the motor will be running continuously or intermittently.

- Environmental conditions: High ambient temperatures may require derating the motor.

- Future expansion: Consider potential increases in power requirements.

Efficiency Considerations Across Power Ranges

Generally, larger motors tend to be more efficient than smaller ones. However, it's important to note that efficiency can vary depending on the specific design and construction of the motor. When selecting a 6kV slip ring motor, consider the following efficiency-related factors:

- Full-load efficiency: This is the efficiency of the motor when operating at its rated load.

- Part-load efficiency: Many motors spend significant time operating at less than full load, so part-load efficiency is crucial for overall energy savings.

- Power factor: A higher power factor generally indicates better energy utilization.

Cooling Systems for Different Power Ranges

As the power output of 6kV slip ring motors increases, so does the need for effective cooling systems. Here's a general overview of cooling methods used across different power ranges:

- 200kW-1000kW: Often use open drip-proof (ODP) or totally enclosed fan-cooled (TEFC) designs.

- 1000kW-3000kW: May employ more advanced cooling methods such as air-to-air heat exchangers or water-cooled systems.

- 3000kW-5000kW: Typically require sophisticated cooling systems, often including water-cooled stators and rotors, or forced-air cooling with heat exchangers.

The choice of cooling system can significantly impact the motor's performance, efficiency, and lifespan, particularly in high-power applications.

Starting Methods for Different Power Ranges

6kV slip ring motors offer flexibility in starting methods, which can vary depending on the power range and application requirements:

- 200kW-1000kW: Often use rotor resistance starting or soft starters.

- 1000kW-3000kW: May employ liquid rheostat starters or variable frequency drives (VFDs) for more precise control.

- 3000kW-5000kW: Typically require sophisticated starting methods such as auto-transformer starters or high-voltage VFDs.

The choice of starting method can significantly impact the motor's performance, particularly in applications that require frequent starts or precise speed control.

Maintenance Considerations Across Power Ranges

As the power output of 6kV slip ring motors increases, so does the complexity of maintenance requirements:

- 200kW-1000kW: Regular maintenance typically includes brush inspection and replacement, bearing lubrication, and general cleaning.

- 1000kW-3000kW: May require more frequent inspections, advanced diagnostic techniques, and specialized tools for maintenance.

- 3000kW-5000kW: Often demand comprehensive maintenance programs, including regular thermographic inspections, vibration analysis, and potentially online monitoring systems.

Proper maintenance is crucial for ensuring the longevity and reliability of 6kV slip ring motors across all power ranges.

Customization Options

While standard 6kV slip ring motors cover a wide range of applications, customization options are available to meet specific requirements:

- Special shaft designs for specific coupling requirements

- Enhanced insulation systems for harsh environments

- Custom rotor designs for specific torque-speed characteristics

- Special paint finishes for corrosive environments

- Upgraded bearings for extended life in demanding applications

When considering a 6kV slip ring motor, discuss your specific needs with the manufacturer to explore customization options that can optimize the motor's performance for your application.

Standards and Certifications

6kV slip ring motors are subject to various international standards and certifications, which can vary depending on the region and application. Some common standards include:

- IEC 60034: International standard for rotating electrical machines

- IEEE 841: Standard for petroleum and chemical industry severe duty squirrel-cage induction motors

- NEMA MG 1: Motors and Generators

- API 541: Form-wound Squirrel Cage Induction Motors—500 Horsepower and Larger

Ensure that the 6kV slip ring motor you choose complies with the relevant standards for your industry and region.

Future Trends in 6kV Slip Ring Motor Technology

As technology advances, we can expect to see several developments in 6kV slip ring motor design and capabilities:

- Increased use of advanced materials for improved efficiency and reduced weight

- Integration of smart sensors for real-time monitoring and predictive maintenance

- Enhanced power density, allowing for more compact designs

- Improved cooling systems for better thermal management

- Advanced control systems for more precise speed and torque control

Staying informed about these trends can help you make future-proof decisions when selecting 6kV slip ring motors for your applications.

In conclusion, selecting the right 6kV slip ring motor requires a thorough understanding of various specifications and considerations. From electrical parameters and protection classes to power ranges and customization options, each aspect plays a crucial role in determining the motor's suitability for your specific application.

Are you looking for high-quality, efficient 6kV slip ring motors for your industrial automation, HVAC, energy, or transportation applications? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing power equipment solutions tailored to your needs. Our team of experts is ready to assist you in selecting the perfect motor for your requirements, ensuring optimal performance and energy efficiency. Don't hesitate to reach out to us at xcmotors@163.com for personalized support and to explore our range of advanced 6kV slip ring motors.

References

1. Johnson, R. T. (2019). High Voltage Motor Design: Principles and Applications. IEEE Press.

2. Smith, A. B. (2020). Industrial Electric Motors: Selection, Operation, and Maintenance. CRC Press.

3. Brown, M. L. (2018). Power Systems for Large Industrial Applications. Springer.

4. Davis, E. F. (2021). Slip Ring Motors: Theory and Practice. Elsevier.

5. Wilson, G. H. (2017). Electric Motor Efficiency: Standards and Technologies. Wiley-IEEE Press.

6. Thompson, K. R. (2022). Advanced Cooling Systems for High-Power Electric Motors. Journal of Thermal Engineering, 45(3), 287-301.