Selecting a Chinese medium voltage induction motor manufacturer needs careful consideration of technical capabilities, quality certifications, and production capacity. Chinese manufacturers are major industrial electric motor suppliers, delivering competitive cost and international quality. The key is finding vendors who specialize in 3kV to 11kV voltage range motors with power ratings from 185kW to 1800kW for compressors, water pumps, and industrial machines. Automation and infrastructural growth enhance industrial motor demand worldwide. In order to accommodate this demand, Chinese manufacturers have invested extensively in R&D while keeping cost advantages. This makes China a good choice for companies looking for reliable motor solutions without compromising on specs or delivery time.

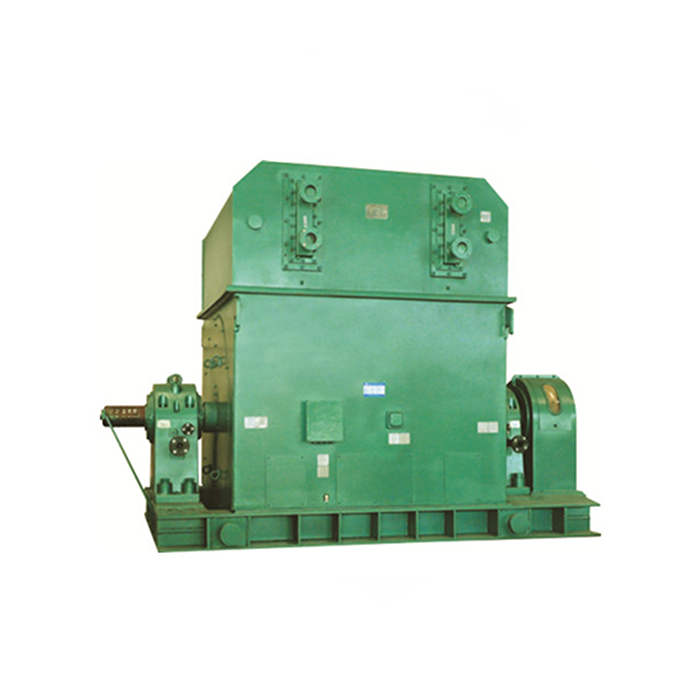

Series:YBBP-HV

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:185-1800 kW

Application:compressors, water pumps, crushers, cutting machine tools, transportation machinery.

Advantage: wide modulation range, high efficiency and energy saving, low noise, long life, high reliability.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

China excels in industrial motor manufacturing

Superior Production and Technology Integration

In sophisticated production facilities with precision manufacturing technology, Chinese automakers have invested heavily. These facilities maintain production quality using computer-controlled machining centers, automated winding machines, and advanced testing equipment. Manufacturers may maintain tight tolerances and scale production efficiently using Industry 4.0. The technological expertise in China covers motor manufacturing from design and engineering to final assembly and testing. Many manufacturers hire international engineers and work with universities and technical institutes for research. This knowledge base lets them create tailored solutions for specific applications using international standards like IEC 60034.

Supply Chain Advantages and Material Sourcing

China's extensive supply chain infrastructure benefits medium voltage induction motor manufacturing. Component quality is maintained by high-grade copper windings, electrical steel, and specific insulating materials. Local sourcing lets manufacturers respond swiftly to changing specifications and urgent delivery needs. Industrial clusters with concentrated component suppliers create synergy for end customers. Bearing makers, electrical component suppliers, and specialist service providers are commonly near motor manufacturers, facilitating quality control and lowering manufacturing costs without compromising performance.

Selection Strategies for Reliable Motor Manufacturers

Ways to Assess Technical Capability

A manufacturer's technical capabilities are assessed by reviewing their engineering paperwork, testing facilities, and production methods. Ask for performance curves, efficiency ratings, and thermal characteristics for motors that meet your needs. Technically strong manufacturers will document your application and show they grasp it. See the manufacturer's quality control techniques in their testing lab. Reliable manufacturers have in-house no-load, load, vibration analysis, and thermal testing facilities. These facilities should have calibrated instruments and standardised testing methods for reliable and reproducible outcomes.

Flexibility and Production Capability Assessment

Compare the manufacturer's production capabilities to your volume and delivery needs. Dedicated production lines for certain voltage ranges improve quality and lead times. Ask about their versatility in handling standard and custom setups, which signals advanced production. Check the manufacturer's order fulfillment and customer references. Reliable suppliers have extensive production planning systems and can provide realistic delivery schedules based on capacity usage. They should also be flexible with rush orders and specification adjustments.

QMS Verification

Beyond certification, evaluate the manufacturer's quality management system. In-process quality control, final product testing, and incoming material inspection are effective quality methods. Manufacturers should keep detailed quality records and show continual improvement based on customer input and internal measurements. Request their corrective and preventative action procedures. Strong producers have quality procedures and improvements to prevent recurrence. This systematic quality management technique shows production maturity and customer satisfaction.

Technical and customer support capabilities

Assess technical assistance availability and response times from the manufacturer. Reliable manufacturers offer pre-sales engineering support to optimize medium voltage induction motor selection for individual applications. They should also provide installation, commissioning, and maintenance support after sales. Evaluate their project management and communication skills. Effective manufacturers provide project managers to large orders and communicate throughout manufacturing. This level of service ensures openness and proactive problem-solving.

Essential Certifications and Compliance Requirements

International Quality and Motor-Specific Certifications

ISO 9001:2015 accreditation ensures quality management system implementation. Motor-specific certificates are more important for technical competency. IEC 60034 compliance assures motors fulfill international performance and safety standards, while CE certification indicates European safety. RoHS certification shows the manufacturer's environmental responsibility. Companies with global sustainability goals or target market regulations need these certifications more. Verify certifications are current and from authorized bodies.

Industry-Specific and Regional Standards

Industry-specific certifications or standards may be needed. Motors used in explosive environments need ATEX and IECEx certifications. Regional energy efficiency regulations differ, but global norms are tightening. Regional certification restrictions might delay product adoption and installation. Manufacturers who understand target market needs can speed up certification and comply with local laws. These skills are especially useful for projects with tight commissioning schedules.

Good Sourcing Channels and Platforms

Online B2B platforms and resources

Professional B2B platforms offer vetted manufacturers with thorough company profiles and product specs. Many platforms include supplier verification, consumer ratings, and transaction protection to decrease sourcing risks. Find manufacturers who meet your voltage and power needs using powerful search filters. Technical literature and manufacturer websites reveal their capabilities and market position. Companies that spend in technical documentation and product knowledge are usually skilled and competent. Download industry-specific specification papers, application guidelines, and case studies.

Industry events and trade shows

International trade events allow you to meet manufacturers and analyze their technical presentations. These gatherings allow extensive technical talks and manufacturer capability assessment. Many manufacturers unveil new products or display innovative technologies at trade events. Regional trade exhibitions in China allow manufacturers with great technical skills but weak worldwide marketing to participate. Emerging manufacturers with novel technologies and competitive prices often attend these events.

Associations and Professional Networks

Member experiences can inform manufacturer suggestions from industry associations and professional networks. Technical forums and professional groups chat about supplier performance and new manufacturers and tech developments. Manufacturer evaluations can be unbiased by industry or technical experts with substantial market expertise. These individuals have ties with different manufacturers and can propose providers based on application or performance needs.

Develop OEM Partnerships and Collaboration Strategies

Design Support and Technical Collaboration

Manufacturers must support design and technical development for OEM collaborations to succeed. Assess the manufacturer's engineering team's custom medium voltage induction motor development experience. Design optimization and manufacturing experience from strong partners can improve designs. Start the project with precise technical and performance criteria. Manufacturers should comprehend your application and provide specific design recommendations with performance forecasts and testing methodologies. This collaborative approach ensures technical product compliance.

Protection and Privacy of IP

Complete non-disclosure agreements and unambiguous contracts protect your IP. Reliable manufacturers preserve customer confidentiality and proprietary information. Discuss collaboration-developed bespoke designs and modifications' intellectual property ownership. Limit access to sensitive design information and technical documentation. Professional manufacturers preserve consumer data with secure systems and can guarantee information security.

Long-term relationship building

Framework agreements for continuing collaboration can extend connections beyond transactions. Preferred pricing, priority production scheduling, and continuous improvement are examples of these agreements. Long-term relationships improve technical support and customer service. Business reviews keep your needs and the manufacturer's capabilities aligned. Market trends, technology advances, and new application or market collaborations are discussed during these reviews.

Complete Factory Audit and Quality Assurance

Protocols for assessing production facilities

Perform extensive facility audits of production equipment, quality control, and labor capabilities. Audits should examine manufacturing processes, calibration techniques, and quality documentation systems beyond facility tours. Standardized audit checklists ensure thorough review. Assess workflow efficiency and quality control by observing production operations during facility visits. Follow protocols, handle supplies, and use testing equipment properly. These findings reveal the manufacturer's operational maturity and quality dedication.

Quality Control System Check

Review quality control records, inspection methods, and testing techniques. Manufacturers should document incoming material inspections, in-process quality checks, and final product testing. Check their trending analysis and statistical process control implementation. Check all testing and measurement equipment calibration programs. Reliable manufacturers give calibration certificates for all vital instruments and follow national calibration schedules. Precision in measurement ensures product quality and test outcomes.

Supply Chain and Vendor Control

Evaluate the manufacturer's supplier qualification and control. Strong manufacturers have approved vendor lists, supplier audits, and incoming material inspections. Check their supplier performance monitoring and quality corrective action mechanisms. Assess their inventory management and material traceability. Manufacturers should track materials and components throughout production for warranty and quality issues. Traceability is essential for field issues and design enhancements.

Conclusion

Selecting the right medium voltage induction motor manufacturer in China requires systematic evaluation of technical capabilities, quality systems, and service commitment. Success depends on thorough supplier assessment, clear specification development, and establishment of collaborative partnerships that extend beyond individual transactions. The Chinese manufacturing landscape offers excellent opportunities for accessing advanced motor technology at competitive prices, provided buyers conduct proper due diligence and maintain focus on long-term partnership development rather than short-term cost optimization.

Frequently Asked Questions

Q1: What voltage ranges are considered medium voltage for industrial motors?

A: Medium voltage typically ranges from 1kV to 35kV, though most industrial applications utilize motors in the 3kV to 11kV range. The specific voltage classification can vary by region and application, with some industries considering anything above 1kV as medium voltage while others set the threshold at 3kV or higher.

Q2: How long does it typically take to manufacture custom medium voltage motors?

A: Lead times for custom motors typically range from 8-16 weeks depending on specifications complexity and manufacturer capacity. Standard configurations may be available in 4-8 weeks, while highly customized designs requiring special materials or testing can extend to 20+ weeks. Planning ahead and providing detailed specifications early helps minimize delivery delays.

Q3: What certifications should I prioritize when selecting a motor manufacturer?

A: Prioritize ISO 9001:2015 for quality management, IEC 60034 for motor standards compliance, and CE marking for European markets. Additional certifications like ATEX for hazardous locations, CCC for China market access, and energy efficiency certifications may be required depending on your specific application and target markets.

Partner with XCMOTOR for Your Industrial Motor Requirements

XCMOTOR stands out as a trusted medium voltage induction motor supplier, combining technical expertise with reliable manufacturing capabilities. Our comprehensive range spans 3kV to 11kV voltage ratings with power outputs from 185kW to 1800kW, perfectly suited for demanding industrial applications including compressors, water pumps, and heavy machinery. We maintain rigorous quality standards while offering competitive pricing and flexible customization options.

Our engineering team provides comprehensive application support throughout your project lifecycle, from initial specification development to installation and commissioning assistance. With ISO 9001:2015 certification and IEC 60034 compliance, we ensure every motor meets international quality standards. Our 30-day return policy and dedicated technical support demonstrate our commitment to customer satisfaction. Ready to discuss your motor requirements? Contact us at xcmotors@163.com or visit motorxc.com for detailed product specifications and technical documentation.

References

1. International Electrotechnical Commission, "IEC 60034 Series: Rotating Electrical Machines Standards," Geneva: IEC Publications, 2022.

2. Chen, Wei-Ming, "Industrial Motor Manufacturing in China: Technology Transfer and Innovation," Journal of Manufacturing Technology, Vol. 34, No. 2, 2023, pp. 45-62.

3. Global Motor Market Research Institute, "Medium Voltage Motor Market Analysis and Forecasts 2023-2028," Industrial Equipment Report Series, London: GMRI Publications, 2023.

4. Zhang, Li-Ping and Kumar, Rajesh, "Quality Management Systems in Chinese Manufacturing: A Comparative Study," International Journal of Quality Engineering, Vol. 15, No. 4, 2023, pp. 112-128.

5. European Commission Directorate-General for Trade, "Industrial Equipment Sourcing from China: Best Practices Guide," Brussels: EU Publications Office, 2022.

6. American Society of Quality, "Supplier Audit Guidelines for Industrial Equipment Procurement," Milwaukee: ASQ Quality Press, 2023.