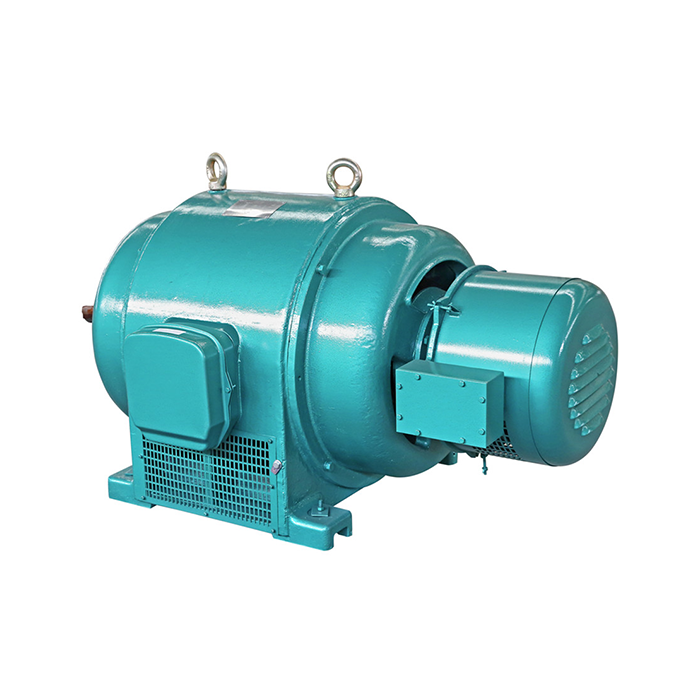

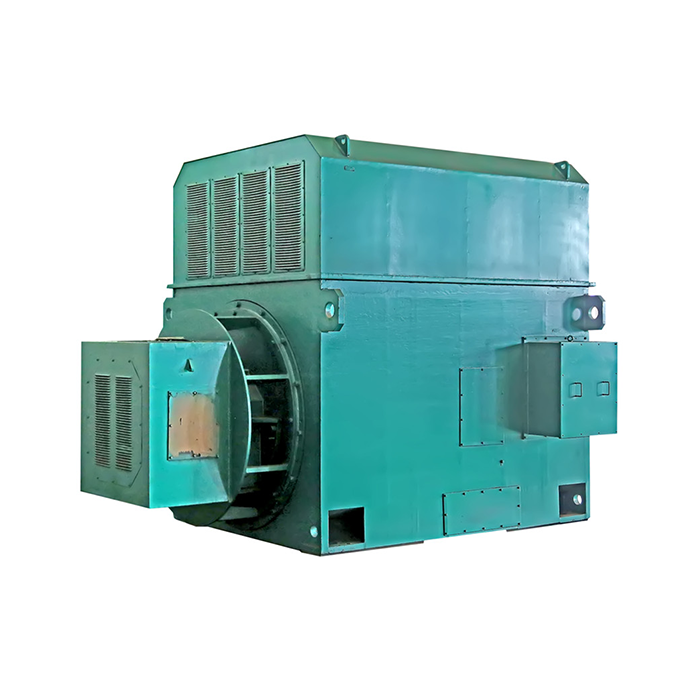

When industrial applications demand exceptional starting torque, YRKK Motor technology stands as a proven solution for heavy-duty operations. These high-voltage motors deliver reliable performance in demanding environments, from steel mills to mining operations. With power ranges spanning 200-4500kW and voltage capabilities up to 11,000V, YRKK motors excel in applications requiring substantial initial force. Their robust design incorporates advanced cooling systems, precision-engineered components, and superior insulation properties, making them indispensable for critical industrial processes where conventional motors fall short.

Series:YRKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-4500 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.2-2002 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High Starting Torque Requirements in Industrial Applications

Industrial mechanization frameworks regularly confront challenging startup conditions where hardware must overcome critical introductory resistance. Fabricating offices in the car, aviation, and gadgets segments frequently experience scenarios where standard engines battle to start development. Prepare control hardware, including heavy-duty pumps, large-scale compressors, and mechanical valves, requires considerable torque at startup to overcome inactive contact and inertia.

The material science behind beginning torque includes overcoming both mechanical resistance and framework dormancy. Overwhelming apparatus, transport frameworks stacked with materials, and expansive fans working in unforgiving conditions all show interesting challenges. Engine control frameworks must convey exact control conveyance while maintaining operational productivity. Flag handling capabilities ended up pivotal when planning different engine frameworks inside complex mechanical robotization networks.

HVAC applications in commercial buildings and mechanical refrigeration frameworks, moreover, require solid beginning torque. Expansive centrifugal fans, cooling tower engines, and refrigeration compressors require engines able of starting operation beneath shifting stack conditions. Vitality and utilities divisions, especially control era offices and water treatment plants, depend on engines that can operate dependably notwithstanding of surrounding conditions or framework stack variations.

Technical Specifications and Performance Characteristics

Modern high-torque engine plan consolidates advanced design standards that optimize execution over differing working conditions. Copper rotor bars upgrade electrical conductivity, while decreasing vitality misfortunes amid startup. High-quality silicon steel laminations minimize center misfortunes, progressing by and large engine proficiency all through the operational spectrum.

Durability and Power Specifications

Protection level IP54 ensures adequate defense against dust ingress and water splashing, making these motors suitable for industrial environments. The voltage range spanning 3000V to 11000V accommodates various power distribution systems commonly found in industrial facilities. Power capabilities from 200kW to 4500kW cover applications from medium-scale process equipment to massive industrial machinery, making a YRKK Motor a versatile power solution for numerous demanding applications.

Advanced Support and Control Systems

Advanced cooling frameworks join optimized wind stream designs and warm scattering advances. Fortified bearing frameworks utilize premium components from producers like SKF, NSK, and FAG, guaranteeing amplified benefit life indeed beneath demanding working conditions. Inserted frameworks inside advanced engine controllers empower prescient upkeep capabilities, diminishing startling downtime and upkeep costs, which is significant for persistent mechanical operations.

Core Manufacturing and Insulation Technologies

Vacuum Weight Impregnation (VPI) innovation gives prevalent separator execution, ensuring windings against dampness, chemicals, and temperature fluctuations. Progressed winding strategies optimize electromagnetic field dissemination, improving beginning torque while maintaining operational proficiency. Accuracy die-casting forms guarantee rotor adjust and dimensional exactness, decreasing vibration and commotion amid operation, contributing to the by and large unwavering quality and life span of the motor.

Manufacturing Excellence and Quality Assurance

Precision Manufacturing and Advanced Winding

The production process for high-starting-torque motors, such as the YRKK Motor, demands exceptional precision and quality control measures. Precision die-casting techniques create rotor components with tight tolerances, ensuring optimal electromagnetic performance and mechanical balance. Advanced winding methods incorporate computer-controlled processes that maintain consistent copper distribution and insulation integrity. This foundational stage is critical for achieving the robust performance and reliability required in demanding industrial applications.

Multifaceted Quality Control and Testing

Quality control conventions incorporate comprehensive testing methods that ensure execution beneath different working conditions. Each engine experiences thorough electrical testing, mechanical vibration examination, and warm-up assessment. Machine learning calculations analyze generation information to recognize potential quality issues, which sometimes affect the last items. These rigid approval steps, which incorporate computerized diagnostics frameworks confirming execution against measures like JB/T10314.2-2002, guarantee each unit meets the most noteworthy unwavering quality criteria.

Intelligent Process Monitoring and Optimization

Sensor integration throughout the fabrication process screens basic parameters counting winding resistance, separator keenness, and bearing clearances. Neural systems prepare this quality information to optimize generation parameters ceaselessly. Information mining procedures recognize relationships between fabricating factors and long-term execution characteristics. Design acknowledgment computer program assist analyzes vibration marks and warm profiles, making a closed-loop framework that proactively upgrades consistency and item longevity.

Application-Specific Solutions Across Industries

Industrial automation applications benefit significantly from motors designed specifically for high starting torque requirements. Manufacturing environments utilizing hoists for material handling depend on reliable motor performance to maintain production schedules. Rolling mill operations in steel production require motors capable of initiating movement despite massive mechanical loads.

Demands of Precision Manufacturing

Wire drawing machines in cable manufacturing facilities present unique challenges where smooth, controlled starting prevents material damage and ensures product quality. These applications demand motors with exceptional torque control characteristics and minimal speed fluctuation during startup phases. This precision is critical in maintaining the integrity of delicate materials throughout the production process.

Infrastructure and Energy Sector Requirements

HVAC systems in large commercial facilities and energy sector applications, particularly in renewable energy installations, benefit from motors designed for reliable operation in harsh or variable conditions. From wind turbine pitch control to the heavy-duty demands of transportation infrastructure like railway systems, these settings require motors with superior starting characteristics and long-term reliability. For instance, a durable YRKK Motor is often specified for such challenging environments due to its robust construction and proven performance under demanding loads.

Integration with Modern Management Systems

Modern industrial applications increasingly rely on integrated management systems. Natural language understanding capabilities in building management and text analysis of maintenance records help coordinate motor operation with overall facility requirements. This integration optimizes energy consumption, predictive maintenance schedules, and operational efficiency, ensuring that motor selection and performance are continuously aligned with broader system demands and data-driven insights.

Installation and Maintenance Best Practices

Proper installation procedures significantly impact motor performance and service life. Foundation requirements must accommodate motor weight and operating forces while minimizing vibration transmission to surrounding structures. Electrical connections require careful attention to voltage ratings, grounding requirements, and environmental protection standards.

Voice recognition systems in modern maintenance protocols enable technicians to document installation parameters and maintenance activities efficiently. AI-driven motors incorporate self-diagnostic capabilities that monitor performance parameters continuously, alerting maintenance personnel to potential issues before they cause equipment failure.

Predictive maintenance strategies utilize sensor data and advanced analytics to optimize maintenance schedules. Vibration analysis, thermal monitoring, and electrical parameter tracking provide early warning indicators of developing problems. Semantic analysis of maintenance logs helps identify common failure modes and optimize preventive maintenance procedures.

Regular inspection schedules should include bearing lubrication, electrical connection integrity, and cooling system performance verification. Motor efficiency monitoring helps identify gradual performance degradation that might indicate developing mechanical or electrical problems. Proper documentation of maintenance activities supports warranty requirements and helps optimize replacement schedules.

Conclusion

High starting torque applications require motors that are purpose-built to withstand severe mechanical and electrical stresses while maintaining stable, long-term performance. YRKK motor technology is designed to meet these demands, delivering reliable operation across a wide range of industries including heavy manufacturing, process industries, power generation, mining, and transportation systems. Key technical features such as IP54 enclosure protection, broad voltage adaptability, reinforced insulation systems, and rugged mechanical structures ensure consistent performance in dusty, humid, or high-temperature environments. Advanced manufacturing techniques, combined with strict quality control procedures, guarantee dimensional accuracy, electrical stability, and repeatable performance from unit to unit. Application-oriented design allows YRKK motors to be matched precisely to load characteristics, improving starting behavior and overall efficiency. Proper installation, alignment, and commissioning are essential to fully realize these benefits, while disciplined maintenance programs help preserve reliability over time. In addition, modern monitoring and diagnostic technologies support predictive maintenance strategies, enabling early fault detection, reduced unplanned downtime, and lower total operating costs throughout the motor’s service life.

Partner with XCMOTOR for Superior High-Torque Motor Solutions

XCMOTOR delivers exceptional YRKK Motor solutions tailored to demanding industrial applications requiring high starting torque performance. Our comprehensive approach combines technical expertise with responsive customer support, ensuring optimal motor selection for your specific requirements. As a trusted YRKK Motor supplier, we provide original components, fast delivery, and dedicated technical assistance. Experience the reliability of professional-grade equipment backed by 30-day returns and continuous support including weekends. Transform your industrial operations with proven motor technology designed for demanding applications. Ready to enhance your facility's performance? Contact us at xcmotors@163.com for expert consultation.

References

1. International Electrotechnical Commission. "Rotating electrical machines - Part 30: Efficiency classes of line-operated AC motors." IEC 60034-30-1:2014.

2. Institute of Electrical and Electronics Engineers. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017.

3. National Electrical Manufacturers Association. "Motors and Generators - MG 1-2016." NEMA Standards Publication MG 1-2016.

4. American Petroleum Institute. "Electrical Equipment for Use in Class I, Zone 0, 1 and 2 Hazardous Locations - General Requirements." API RP 505:2018.

5. International Organization for Standardization. "Industrial automation systems and integration - Manufacturing execution systems." ISO 15704:2019.

6. European Committee for Electrotechnical Standardization. "Rotating electrical machines - Part 1: Rating and performance." EN 60034-1:2010+A1:2014.