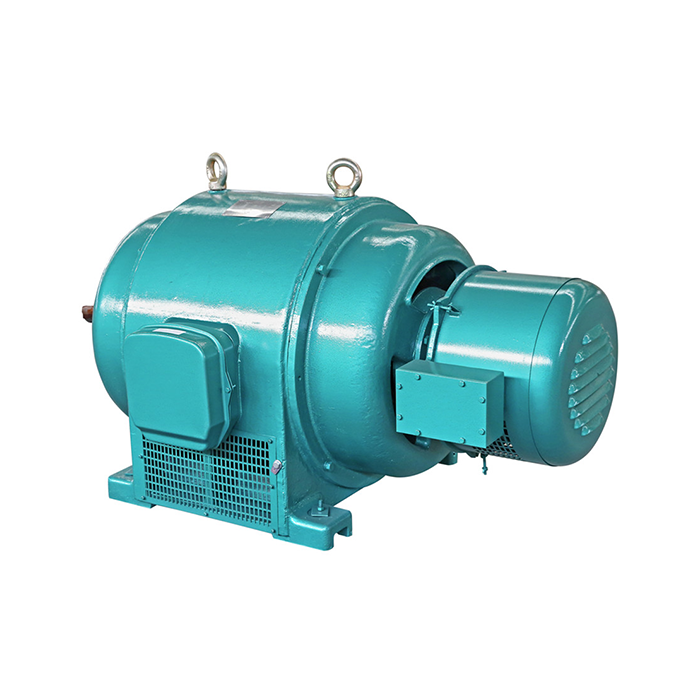

slip ring motor

Voltage range:380V±5%

Power range:45-710kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

Slip Ring Motor - High Performance YRQ Series for Industrial Applications

The YRQ series wound rotor motor provides superior control over starting current and torque compared to conventional motors. With power ranging from 45-710kW and excellent overload capacity, this slip ring motor ensures smooth operation even under challenging conditions. Our motors feature external rotor resistance control through slip rings, making them ideal for applications requiring controlled acceleration and variable speed operation.

Product Description

Product Description

The YRQ series wound rotor motor represents advanced engineering in industrial power transmission. Designed for demanding applications, this motor provides precise control over starting characteristics through its slip ring configuration. You'll benefit from reduced starting current impact on your electrical system while maintaining high starting torque for heavy loads.

Product Specifications

| Item | Specification |

|---|---|

| Series | YRQ |

| Voltage Range | 380V±5% |

| Power Range | 45-710kW |

| Protection Level | IP23 |

| Starting Current | 2-3 times rated current |

| Starting Torque | 1.8-2.5 times rated torque |

| Overload Capacity | 3-4 times rated torque for 15-30 seconds |

| Temperature Rise | Below 120℃ (Class B insulation) |

Product Details

Our wound rotor design incorporates multi-strand copper wire windings and optimized rotor core laminations. The external slip ring assembly allows for flexible resistance control during startup and operation. Depending on your needs, premium bearings from SKF, NSK, or FAG can be selected.

Production Process

Throughout the production process, each motor is subjected to strict quality control. Our manufacture adheres to ISO9001:2000 standards, guaranteeing dependability and constant performance. Before being sent, every device is put through a rigorous testing process that includes performance verification, vibration levels, and insulating resistance.

Application Scenarios

This slip ring motor excels in driving:

- Crushers and ball mills

- Heavy-duty conveyor systems

- Large compressors and pumps

- Mining equipment

- Wind turbines and industrial fans

- Ship propulsion systems

- Material handling equipment

Industries benefiting include coal mining, metallurgy, power generation, and heavy manufacturing where controlled starting and impact load resistance are essential.

Why Choose XCMOTOR

With more than two decades of expertise, we continue to collaborate with top manufacturers such as Siemens, Wolong, and ABB. You will acquire the appropriate motor specification for your application thanks to our knowledge.

We provide:

- Original parts from trusted brands only

- Fast delivery with free shipping

- 30-day return policy

- Dedicated weekend support

- Competitive pricing and optimal delivery schedules

- Customized transportation solutions

Our strong supplier network, mature R&D team, and SAP factory management system guarantee quality and reliability.

Qualification Certification

International standards are ensured by the extensive certifications that all goods have, such as CCC, CE, ISO9001:2000, CRCC, CQC, ZDHY environmental management, China energy saving certification.

FAQ

Q: How does starting current compare to squirrel cage motors?

A: Our wound rotor motors limit starting current to 2-3 times rated current, significantly lower than the 5-7 times typical of squirrel cage designs.

Q: What maintenance is required?

A: External slip rings and brushes require periodic inspection and cleaning. Annual maintenance costs typically represent only 6%-9% of equipment purchase cost.

Q: Can you customize specifications?

A: Yes, we adjust dimensions and specifications according to your specific requirements while maintaining performance standards.

Contact Us

Ready to discuss your slip ring motor requirements? Our technical team is available to help select the optimal solution for your application. Contact Us at XCMOTORs@163.com" target="_blank">xcmotors@163.com for detailed specifications, pricing, and delivery information. We're committed to providing you with reliable power solutions backed by expert support.