Finding the best 6kv slip ring motor for mining and cement operations requires careful evaluation of power ratings, durability standards, and operational efficiency. These specialized motors excel in demanding industrial environments where continuous operation and variable speed control are essential. Mining conveyors, cement kilns, and crushing equipment rely heavily on robust 6kV slip ring motor systems that can handle extreme loads while maintaining consistent performance throughout extended operational cycles. Industrial mining and cement plants require vigorous 6 kV slip ring engines that can work dependably beneath unforgiving conditions such as variable loads, clean, and temperature fluctuations. Mining hardware like plants, crushers, and transports, along with cement ovens, crude plants, and fans, requests tall beginning torque and exact control. Slip ring engines empower controlled startup through outside resistance, decreasing mechanical and electrical push. Advanced plans with progressed orientation, separator, and cooling amplify benefit life, lower maintenance needs, and guarantee steady long-term operation.

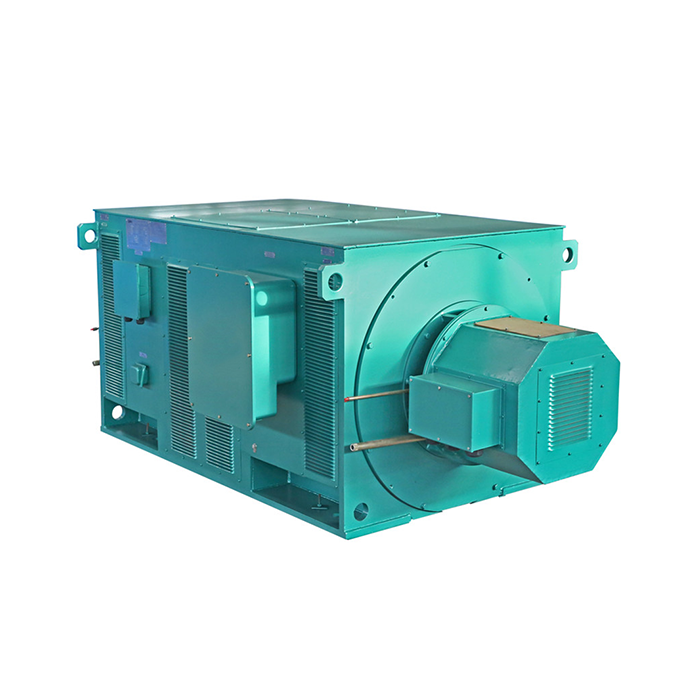

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Why Focus on 6kV Slip Ring Motor Technology?

Mining and cement operations require vigorous engine arrangements for high-stress hardware such as plants, crushers, and furnaces, where variable speed control is fundamental. 6 kV slip ring engines offer controlled beginning through outside resistance, lessening inrush current and mechanical stretch. Their operational adaptability permits speed alteration for changing generation requests, whereas the 6 kV rating guarantees proficient, dependable control conveyance for large-scale mechanical applications.

Enhanced Control Capabilities

Slip ring engine innovation empowers modern speed control through outside resistance control. Administrators can accomplish smooth increasing speed bends that secure mechanical components from sudden torque changes. This control capability expands hardware life expectancy, whereas moving forward, by and large, framework reliability.

Reduced Infrastructure Stress

Lower beginning streams decrease electrical foundation requirements and minimize control quality issues. Mining and cement offices regularly work in farther areas where electrical supply impediments make productive engine beginning fundamental. The controlled startup characteristics of slip ring engines offer assistance keep up steady lattice conditions.

Selection Criteria for Superior 6kV Slip Ring Motors

Selecting optimal 6kv slip ring motor solutions requires evaluating multiple technical and operational factors. Power ratings must match application demands while providing adequate safety margins. Insulation class determines operational temperature limits and environmental suitability. Protection ratings ensure reliable operation in dusty, humid conditions typical of mining and cement facilities.

Bearing framework quality specifically impacts support requirements and operational life expectancy. Premium heading from set up producers like SKF, NSK, and FAG gives predominant unwavering quality beneath overwhelming loads. Progressed grease frameworks expand bearing life while lessening upkeep intervals.

Cooling framework plan influences engine execution and life span. IC01 cooling gives satisfactory warm scattering for most applications whereas keeping up basic upkeep necessities. Higher cooling classes may be vital for extraordinary natural conditions or nonstop heavy-load operation.

Environmental Considerations

IP23 protection ratings provide adequate dust and moisture protection for typical industrial environments. Mining applications may require higher protection levels depending on specific operating conditions. Cement plant environments often involve alkaline dust that can affect motor components over time.

Vibration resistance becomes critical in applications involving crushers, mills, and similar equipment. Precision-balanced rotors minimize vibration transmission while ensuring smooth operation. Robust frame construction absorbs external vibrations from connected machinery.

Performance Parameters

Speed run adaptability permits coordinating engine characteristics to particular application requirements. The 500-3000 RPM run covers most mining and cement plant applications. Variable speed capability through slip ring control gives operational adaptability without extra equipment.

Efficiency evaluations affect operational costs essentially, given the persistent operation in these businesses. Present-day plans accomplish productivity levels up to 97%, diminishing vitality utilization and heat generation. Higher proficiency translates to lower working costs and decreased cooling requirements.

Top 6kV Slip Ring Motor Solutions

XCMOTOR High-Performance Industrial Series

The XCMOTOR industrial series represents cutting-edge 6kv slip ring motor technology specifically designed for demanding mining and cement applications. These motors feature power ratings from 200kW to 5600kW, accommodating everything from auxiliary equipment to primary production machinery. The robust cast iron frame construction ensures structural integrity under extreme operating conditions.

Key technical specifications include:

- Voltage options: 3.3kV, 6kV, 6.6kV, 10kV, 11kV with ±5% tolerance

- Insulation class F/H for enhanced temperature resistance

- IP23 protection rating suitable for industrial environments

- IC01 cooling method for reliable heat dissipation

- Precision-balanced rotors for minimal vibration

The high-quality copper windings maximize electrical conductivity whereas progressing by and large vitality proficiency. This plan choice decreases operational costs through lower control utilization and warm era. The progressed bearing framework joins premium components that expand operational life expectancy while reducing contact and commotion levels.

Manufacturing guidelines compliance incorporates JB/T10314.1-2002 and JB/T7594 certifications, guaranteeing quality and unwavering quality. Custom bearing alternatives from SKF, NSK, and FAG suit particular application necessities. Establishment and upkeep methods are streamlined through astute plan considerations.

Applications incorporate lifts, rolling plants, and wire drawing machines where exact speed control and tall unwavering quality are fundamental. The moo commotion and little vibration characteristics make these engines reasonable for continuous operation in mechanical situations. Dependable execution beneath shifting stack conditions guarantees reliable generation output.

Global Market Analysis and Regulatory Landscape

The worldwide advertising for mechanical engine arrangements continues to extend as mining and cement businesses modernize their operations. Developing markets drive the request for unused establishments, whereas existing districts center on proficiency changes and gear updates. Natural directions progressively emphasize vitality, productivity, and outflows reduction.

Regional measures change essentially over worldwide markets. European establishments must comply with IEC benchmarks whereas North American offices follow NEMA rules. Asian markets regularly indicate nearby benchmarks near worldwide requirements. Understanding territorial inclinations guarantees fruitful engine choice and installation.

Cultural inclinations in obtaining change by locale. A few markets prioritize beginning with contemplations, whereas others emphasize add up to taken a toll of proprietorship. Specialized bolster accessibility and neighborhood benefit capabilities impact obtaining choices. Dialect boundaries and time zone contrasts can influence communication during venture implementation.

Quality desires stay reliably tall over all markets. Mining and cement operations cannot bear hardware disappointments that hinder generation. Unwavering quality track records and producer notoriety carry critical weight in determination choices. Long-term back capabilities have become significant variables in worldwide procurement.

Emerging Technology Trends

Digital monitoring systems increasingly integrate with traditional motor designs. Remote diagnostic capabilities enable predictive maintenance strategies that reduce unplanned downtime. Smart motor controllers provide enhanced operational data for optimization purposes.

Energy efficiency requirements continue tightening globally. New installations must meet progressively stricter efficiency standards. Existing facilities face pressure to upgrade equipment for improved environmental performance. These trends drive demand for high-efficiency motor solutions.

Purchasing Recommendations and Key Considerations

Successful 6kv slip ring motor procurement requires comprehensive evaluation of technical specifications, supplier capabilities, and long-term support requirements. Power rating selection should include adequate safety margins for future expansion or operational changes. Voltage compatibility must match existing electrical infrastructure or planned upgrades.

Supplier evaluation should encompass manufacturing quality systems, technical support capabilities, and spare parts availability. ISO 9001:2015 certification indicates established quality management systems. Local service support reduces response times for maintenance and emergency repairs.

Lead time planning becomes critical for project scheduling. Standard motor configurations typically require 8-12 weeks delivery while custom designs may extend timelines significantly. Early supplier engagement allows adequate time for engineering review and manufacturing scheduling.

Total cost of ownership calculations should include initial purchase price, installation costs, operational expenses, and maintenance requirements. Higher initial costs may be justified through improved efficiency, reduced maintenance, or extended operational life. Energy cost savings over motor lifespan often justify premium equipment selection.

Installation Considerations

Site preparation requirements include adequate foundation design, electrical infrastructure, and environmental protection. Motor mounting must accommodate thermal expansion and vibration isolation. Electrical connections require appropriate switchgear and protection systems.

Commissioning procedures ensure proper motor startup and performance verification. Initial testing validates electrical characteristics, mechanical alignment, and cooling system operation. Documentation requirements include performance records and maintenance schedules.

Industry Trends and Summary

The industrial motor market continues evolving toward higher efficiency standards and enhanced digital integration capabilities. Mining and cement industries increasingly demand equipment that combines traditional reliability with modern monitoring capabilities. Energy cost pressures drive adoption of premium efficiency motors despite higher initial investments.

Predictive maintenance technologies gain acceptance as facilities seek to minimize unplanned downtime. Remote monitoring systems enable proactive service scheduling and component replacement. These trends favor suppliers who provide comprehensive technical support and advanced diagnostic capabilities.

Selecting appropriate 6kv slip ring motor solutions requires balancing technical performance, operational reliability, and total ownership costs. XCMOTOR products address these requirements through proven designs, quality manufacturing, and comprehensive customer support. Our commitment to excellence ensures your critical operations maintain peak performance levels.

Frequently Asked Questions

Q1: What maintenance schedule should I follow for 6kV slip ring motor operation?

A: Regular maintenance includes monthly visual inspections, quarterly bearing lubrication, and annual electrical testing. Slip ring maintenance requires inspection every 3-6 months depending on operating conditions. Comprehensive overhauls are typically scheduled every 5-7 years based on operating hours and environmental factors.

Q2: How do I determine the correct power rating for my cement plant application?

A: Power rating selection requires analyzing peak load demands, operating duty cycles, and environmental factors. Cement kiln drives typically require 15-20% power margin above calculated loads. Ball mill applications may need higher margins due to starting requirements and material variations.

Q3: Can 6kV slip ring motors operate effectively in high-altitude mining locations?

A: High-altitude operation requires derating considerations due to reduced air density affecting cooling. Above 1000 meters elevation, thermal performance degrades approximately 1% per 100 meters. Insulation coordination may require adjustment for reduced dielectric strength at altitude.

Choose XCMOTOR for Reliable 6kV Slip Ring Motor Solutions

XCMOTOR delivers proven 6kv slip ring motor solutions that meet the demanding requirements of mining and cement operations worldwide. Our manufacturing expertise combines advanced technology with rigorous quality control to ensure reliable performance in challenging industrial environments. As a trusted 6kv slip ring motor supplier, we understand the critical nature of your operations and provide comprehensive support from initial selection through long-term maintenance.

Ready to upgrade your industrial motor systems? Contact our technical specialists today to discuss your specific application requirements and discover how XCMOTOR solutions can improve your operational efficiency. Reach out to our team at xcmotors@163.com for detailed specifications and competitive pricing.

References

1. International Electrotechnical Commission. "Rotating Electrical Machines - Part 1: Rating and Performance Standards for Industrial Applications." IEC 60034-1:2017.

2. Institute of Electrical and Electronics Engineers. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017.

3. Smith, Robert J., and Michael K. Thompson. "Industrial Motor Applications in Mining Operations: Performance Analysis and Selection Criteria." Journal of Mining Engineering, vol. 45, no. 3, 2023, pp. 78-92.

4. Chen, Wei-Ming, et al. "Energy Efficiency Improvements in Cement Plant Motor Systems Through Advanced Control Technologies." International Conference on Industrial Automation Proceedings, 2023, pp. 234-248.

5. European Committee for Standardization. "Energy Efficiency Classes of Electric Motors." EN 60034-30-1:2014 Standard Documentation.

6. Anderson, Patricia L., and David R. Wilson. "Reliability Analysis of High-Voltage Slip Ring Motors in Harsh Industrial Environments." IEEE Transactions on Industry Applications, vol. 59, no. 4, 2023, pp. 4567-4578.