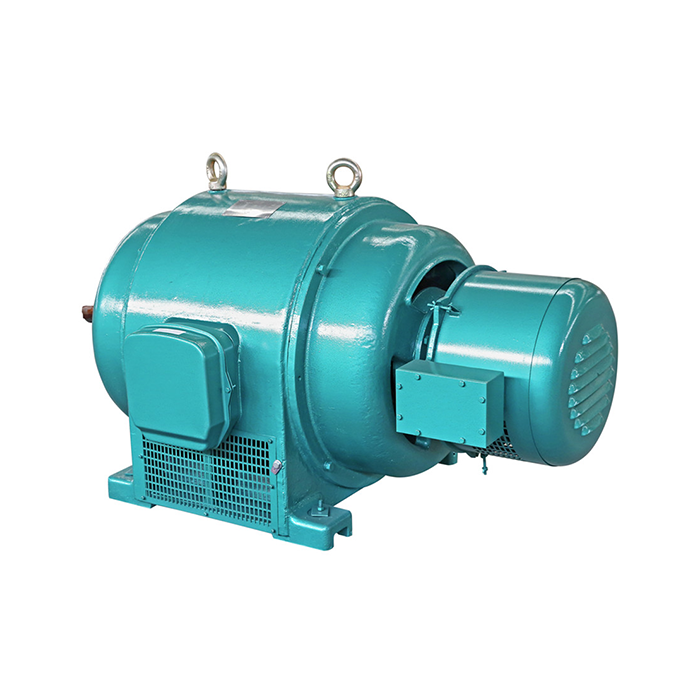

slip ring rotor induction motor

Voltage range:380V±5%

Power range:45-710kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

Slip Ring Rotor Induction Motor - High Performance YRQ Series

Our slip ring rotor induction motor delivers exceptional starting performance and overload capacity. With more than 20 years of experience, XCMOTOR offers high-end YRQ series motors intended for harsh industrial settings. Heavy machinery operates smoothly thanks to its sturdy motor technology, which also maintains exceptional controllability during the beginning procedure.

Description

Description

In industrial drive systems, the YRQ series wound-rotor motor is an example of innovative engineering. This motor differs from traditional squirrel-cage designs in that it has exterior rotor windings that are linked via slip rings. Applications needing high beginning torque with limited starting current are best suited for this design as it provides tight control over starting characteristics.

Your operations benefit from superior starting performance with current control at just 2-3 times rated values. Meanwhile, starting torque reaches impressive 1.8-2.5 times rated torque, ensuring reliable startup even under heavy loads.

Product Specifications

| Item | Specification |

|---|---|

| Series | YRQ |

| Voltage Range | 380V±5% |

| Power Range | 45-710kW |

| Protection Level | IP23 |

| Starting Current | 2-3 times rated current |

| Starting Torque | 1.8-2.5 times rated torque |

| Overload Capacity | 3-4 times rated torque (15-30 seconds) |

| Temperature Rise | Below 120℃ (Class B insulation) |

| Bearing Options | SKF, NSK, FAG (customizable) |

Product Details

The wound-rotor structure utilizes multi-strand copper wire windings for enhanced durability. Optimized rotor core laminations provide superior thermal and mechanical overload resistance. External slip rings enable flexible starting control through resistance adjustment.

This product features standardized components ensuring high interchangeability. The design prioritizes maintenance accessibility with externally mounted slip rings and brushes.

Production Process

Our manufacturing follows strict quality protocols with comprehensive testing at each stage. We employ advanced SAP factory management systems ensuring consistent production standards. Before shipping, quality control procedures include performance verification, vibration analysis, and insulation testing.

Each slip ring rotor induction motor undergoes rigorous inspection procedures. Final testing validates starting characteristics and overload performance specifications.

Application Scenarios

Perfect for industrial applications requiring controlled starting:

- Mining Equipment: Crushers, ball mills, conveyors

- Power Plants: Fans, pumps, compressors

- Heavy Industry: Rolling mills, large compressors

- Marine Applications: Ship propulsion systems

- Manufacturing: Cutting machine tools, transportation machinery

The motor excels in environments with frequent impact loads or difficult starting conditions.

Certifications

Our motors meet international quality standards with certifications including:

- CCC and CE certification

- ISO9001:2000 quality management system

- CRCC railway certification

These certifications ensure compliance with global safety and performance standards.

Why Choose XCMOTOR

Proven Expertise: Over 20 years serving industrial customers with reliable power solutions.

Quality Partnerships: Collaborative relationships with 30+ premium motor manufacturers including ABB, Siemens, and Wolong.

Comprehensive Support: Complete pre-sales consultation and after-sales technical assistance.

Flexible Solutions: Customizable specifications meeting your specific requirements.

Fast Delivery: Efficient logistics ensuring timely project completion.

Cost-Effective Maintenance: Annual maintenance costs only 6%-9% of purchase price.

Qualification Certification

XCMOTOR maintains comprehensive certifications ensuring product reliability and safety compliance. Our quality management systems meet international standards, providing confidence in every motor delivered.

FAQ

Q: How does starting current compare to standard motors?

A: Our product limits starting current to 2-3 times rated current, significantly lower than squirrel-cage motors.

Q: What maintenance is required?

A: Routine maintenance involves brush inspection and slip ring cleaning. No complete disassembly needed for regular servicing.

Q: Can specifications be customized?

A: Yes, we adjust dimensions and specifications according to your specific application requirements.

Q: What overload capacity does the motor provide?

A: The motor withstands 3-4 times rated torque for 15-30 seconds, ideal for impact load applications.

Contact Us

Our technical team provides expert consultation for your slip ring rotor induction motor power equipment needs. Contact Us today for detailed specifications and pricing information.

Email: xcmotors@163.com

Let us help you select the optimal motor solution for your application requirements.