High-power equipment demands reliable, efficient motor solutions that can handle substantial electrical loads while maintaining optimal performance. The 6600v motor emerges as the preferred choice for industrial applications requiring exceptional power delivery and operational stability. These medium voltage motors operate at precisely 6600 volts, providing the perfect balance between power transmission efficiency and safety requirements. Their robust design makes them indispensable for heavy-duty applications across manufacturing, power generation, and process control systems. With superior electrical characteristics and proven reliability, these motors deliver consistent performance even under demanding operational conditions.

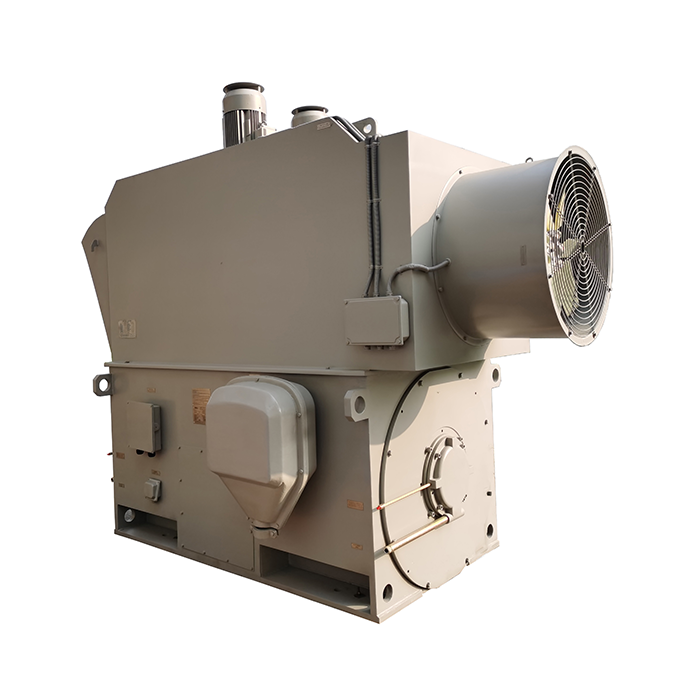

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Key Parameters of 6600V Motor Systems

Medium voltage motors operating at 6600 volts possess specific electrical characteristics that distinguish them from standard low voltage alternatives. The voltage rating represents the nominal operating voltage, while power ratings typically range from 500 kW to several megawatts. Current ratings vary based on power output, with typical values spanning 50 to 500 amperes depending on motor size and application requirements.

Motor efficiency ratings for high voltage motor systems typically exceed 95%, significantly higher than their low voltage counterparts. The power factor usually ranges between 0.85 to 0.95, indicating excellent reactive power characteristics. Starting current ratios remain relatively low, typically 4-6 times the full load current, reducing electrical stress on power systems during startup sequences.

Insulation systems in these industrial motor designs utilize Class F or Class H materials, providing thermal resistance up to 180°C. Motor winding configurations employ specialized insulation techniques to withstand the elevated voltage stresses. Protection ratings commonly reach IP55 or IP56, ensuring adequate protection against dust and moisture in harsh industrial environments.

Core Benefits That Make 6600V Motors Superior

The primary advantage of medium voltage operation lies in reduced current requirements for equivalent power output. Lower current translates to smaller cable sizes, reduced electrical losses, and decreased infrastructure costs. This fundamental principle makes 6600v motors economically attractive for high-power applications.

Motor efficiency improvements become pronounced at higher voltage levels. Reduced current flow minimizes resistive losses in motor windings and connected cables. The efficiency gains compound over extended operating periods, resulting in substantial energy cost savings for continuous-duty applications.

Variable frequency drive compatibility represents another significant benefit. Modern VFD systems designed for medium voltage applications provide precise motor control while maintaining high efficiency across varying load conditions. This capability proves essential for applications requiring speed regulation or soft starting capabilities.

Mechanical advantages include enhanced motor torque characteristics and improved speed regulation. The higher voltage allows for optimized motor design configurations that deliver superior performance compared to multiple smaller motors. Maintenance requirements decrease due to fewer rotating components and simplified mechanical systems.

XCMOTOR's 6600V Motors Versus Competitive Solutions

XCMOTOR's engineering team has developed advanced insulation systems that exceed industry standards for dielectric strength and thermal endurance. Our motor winding techniques utilize premium materials sourced exclusively from trusted suppliers, ensuring consistent quality and extended operational life.

Motor cooling systems in XCMOTOR products feature enhanced heat dissipation designs that maintain optimal operating temperatures even under extreme load conditions. The proprietary cooling configurations reduce bearing temperatures and extend lubrication intervals compared to conventional designs.

Quality assurance protocols at XCMOTOR include comprehensive testing procedures that verify motor protection systems, insulation integrity, and performance characteristics. Each motor undergoes rigorous testing to confirm compliance with international motor standards and customer specifications.

Customer support distinguishes XCMOTOR from competitors through dedicated technical assistance available seven days per week. Our fast delivery commitment ensures minimal project delays, while the 30-day return policy provides purchase confidence for customers evaluating motor applications.

Maximizing Benefits Through Proper Implementation

Selecting the appropriate motor requires careful analysis of load characteristics, operating environment, and performance requirements. Consider factors such as starting torque requirements, duty cycle patterns, and ambient temperature conditions when specifying motor parameters.

Installation procedures should follow established guidelines for medium voltage equipment. Proper grounding techniques, cable routing practices, and environmental protection measures ensure safe and reliable operation. Motor mounting configurations must accommodate thermal expansion and vibration isolation requirements.

Motor maintenance schedules should include regular inspection of bearing conditions, insulation resistance measurements, and vibration monitoring. Preventive maintenance programs significantly extend motor life while reducing unexpected downtime costs. Lubrication schedules must align with manufacturer recommendations and operating conditions.

Performance optimization involves monitoring power factor, current balance, and temperature trends during normal operation. These parameters provide early indication of developing issues and allow for proactive maintenance interventions. Documentation of operating history facilitates troubleshooting and maintenance planning activities.

Critical Applications Across Industries

- Manufacturing facilities utilize these motors for large compressors, industrial pumps, and material handling systems. Automotive production lines depend on reliable motor performance for stamping presses, conveyor systems, and assembly equipment. The consistent power delivery ensures production quality and minimizes costly downtime events.

- Power generation facilities employ medium voltage motors for cooling water pumps, fuel handling equipment, and auxiliary power systems. Renewable energy installations utilize these motors in wind turbine pitch control systems and solar tracking mechanisms. Water treatment plants rely on them for high-capacity pumps and aeration systems.

- Process control applications in chemical and petrochemical industries demand the reliability and performance characteristics of 6600v motor systems. These environments require motors capable of continuous operation under challenging conditions while maintaining precise speed control and torque delivery.

- HVAC systems in large commercial and industrial facilities benefit from the efficiency and control capabilities of medium voltage motors. Commercial refrigeration systems utilize these motors for large compressors and circulation pumps, achieving energy savings through improved motor efficiency and control flexibility.

Important Operational Considerations

Safety protocols for medium voltage equipment require specialized training and protective equipment. Personnel working with 6600v systems must understand electrical hazards and follow established lockout/tagout procedures. Arc flash protection and proper personal protective equipment remain essential for safe operation and maintenance activities.

Environmental factors significantly impact motor performance and longevity. Altitude, ambient temperature, and humidity levels affect motor ratings and cooling requirements. Corrosive atmospheres may necessitate special protective coatings or enclosure modifications to ensure reliable operation.

Electrical system compatibility requires careful consideration of supply characteristics, including voltage regulation, harmonic content, and fault current capabilities. Motor protection systems must coordinate with upstream protective devices to ensure selective operation during fault conditions.

Synchronous motor applications require additional considerations for excitation systems and power factor control. These motors provide reactive power support for electrical systems while maintaining precise speed regulation. Proper commissioning and tuning ensure optimal performance and power quality benefits.

Conclusion

The compelling advantages of 6600v motors for high-power equipment applications stem from their superior efficiency, reduced infrastructure requirements, and enhanced control capabilities. These medium voltage solutions deliver measurable benefits through lower operating costs, improved reliability, and simplified system architectures. Industries spanning manufacturing, power generation, and process control continue to adopt these motors for critical applications requiring dependable performance.

XCMOTOR's commitment to quality and customer support positions us as the preferred partner for organizations seeking premium motor solutions. Our comprehensive product offerings, technical expertise, and responsive service ensure successful project outcomes and long-term operational success.

Frequently Asked Questions

Q1: What makes 6600V motors more efficient than lower voltage alternatives?

A: Higher voltage operation reduces current requirements for equivalent power output, minimizing resistive losses in motor windings and cables. This fundamental relationship results in efficiency improvements of 2-4% compared to low voltage motors of similar power ratings.

Q2: How do variable frequency drives work with 6600V motors?

A: Medium voltage VFDs utilize advanced semiconductor technology to provide precise speed control while maintaining high efficiency. These drives offer soft starting capabilities, energy savings during partial load operation, and improved process control compared to traditional starting methods.

Q3: What maintenance requirements are specific to 6600V motors?

A: Regular insulation resistance testing, bearing lubrication, and vibration monitoring form the core maintenance activities. Annual insulation testing ensures continued dielectric integrity, while bearing maintenance intervals typically extend 6-12 months depending on operating conditions and environmental factors.

Partner with XCMOTOR for Superior 6600V Motor Solutions

XCMOTOR stands as your trusted 6600v motor supplier, delivering cutting-edge solutions tailored to demanding industrial applications. Our comprehensive product line addresses diverse power requirements while maintaining the highest quality standards throughout the manufacturing process. Whether you need a single motor or multiple units for large-scale projects, our team provides expert guidance to ensure optimal selection and implementation.

Our commitment to customer success extends beyond product delivery through comprehensive technical support and application engineering services. The engineering team collaborates closely with customers to optimize motor specifications and integration requirements. This partnership approach ensures successful project outcomes and long-term operational reliability.

Experience the XCMOTOR advantage through our streamlined procurement process and responsive customer service. Our original products sourcing from trusted brands guarantees authentic components and reliable performance. Ready to enhance your operations with premium 6600v motor technology? Contact us at xcmotors@163.com to discuss your specific requirements and discover how our solutions can drive your success.

References

- IEEE Standard 841-2009: IEEE Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors

- NEMA MG 1-2016: Motors and Generators Standard, National Electrical Manufacturers Association

- IEC 60034-1:2017: Rotating electrical machines - Part 1: Rating and performance, International Electrotechnical Commission

- Bonnett, Austin H. "Medium Voltage Motor Applications and Maintenance." IEEE Industry Applications Magazine, Vol. 24, No. 3, 2018

- Finley, William R. "Selection and Application of Medium Voltage Motors." IEEE Petroleum and Chemical Industry Conference, 2019

- Chapman, David. "High Voltage Motor Protection and Control Systems." IEEE Transactions on Industry Applications, Vol. 55, No. 4, 2019