When searching for the best 20 hp dc electric motor options for industrial applications, you'll find motors from Baldor-Reliance, ABB, Siemens, WEG, and Marathon Electric leading the market. These manufacturers consistently deliver reliable performance across manufacturing, HVAC systems, and automation processes. The right motor selection depends on your specific torque output requirements, voltage rating needs, and environmental conditions. Each model offers unique advantages in motor efficiency, speed regulation capabilities, and maintenance requirements that directly impact your operational costs.

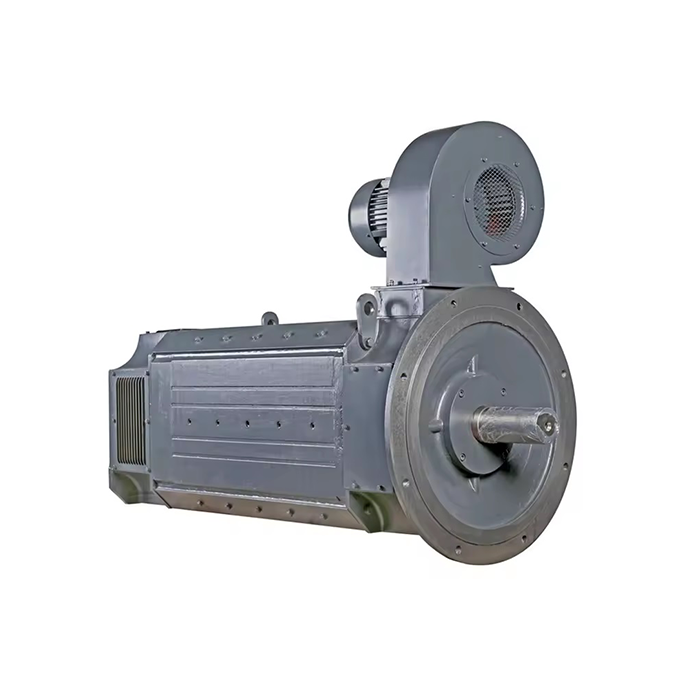

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Why Focus on 20 HP DC Electric Motors

The 20 horsepower rating represents a sweet spot in industrial motor applications, providing substantial power while maintaining manageable installation and operational requirements. This power level handles demanding industrial automation tasks without the complexity of larger motor systems.

DC motors offer superior speed control compared to AC alternatives, making them essential for applications requiring precise variable speed operation. The electromagnetic field characteristics of DC motors provide consistent torque output across wide speed ranges, crucial for manufacturing processes requiring exact control.

Energy consumption considerations make 20 hp motors attractive for mid-sized operations. They deliver sufficient power for substantial loads while maintaining reasonable operating costs. The motor controller integration possibilities allow for sophisticated automation systems that enhance productivity.

Industrial facilities benefit from the reliability these motors provide. Their robust motor housing and armature winding designs withstand harsh operating conditions common in manufacturing environments. The brushless motor variants offer extended service life with minimal maintenance requirements.

Selection Criteria for Best 20 HP DC Motors

- Torque output characteristics determine suitability for specific applications. High starting torque motors excel in heavy-duty applications, while constant torque designs suit continuous operation requirements. The motor shaft configuration must match your mechanical coupling needs.

- Voltage rating compatibility ensures proper integration with existing power supply systems. Common industrial voltages include 240V, 480V, and 600V configurations. Matching voltage requirements prevents costly electrical modifications.

- Environmental durability encompasses motor cooling capabilities, enclosure ratings, and temperature tolerance. Industrial environments demand motors withstanding dust, moisture, and temperature variations. Proper gear reduction compatibility expands application possibilities.

- Manufacturer reputation and support availability influence long-term satisfaction. Established brands provide reliable warranty coverage, technical support, and replacement parts availability. Local service networks ensure minimal downtime during maintenance periods.

Top 6 Selected 20 HP DC Electric Motors

1. XCMOTOR

The 20 HP DC electric motor from Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. offers several key advantages, making it ideal for demanding industrial applications. With a robust design and precision engineering, the motor ensures reliable performance in a wide range of settings, including machine tools, conveyors, pumps, and packaging equipment. Its advanced cooling system and high-quality materials contribute to its extended lifespan and consistent operation under challenging conditions, while its compact size makes it easy to install in limited spaces.

One of the standout features of this motor is its high energy efficiency, with an impressive efficiency rating of 91%. This not only reduces operational power costs but also helps businesses maintain high productivity while minimizing environmental impact. Additionally, the motor's overload capacity of 150% for 60 seconds ensures resilience under sudden load changes, further enhancing its suitability for dynamic industrial environments.

XCMOTOR's commitment to quality is evident in the motor's rigorous manufacturing process, which includes comprehensive testing for durability, safety, and performance. With certifications such as ISO 9001:2015 and CE, customers can trust in the motor's compliance with international standards. XCMOTOR also provides dedicated customer support, fast delivery, and a 30-day return policy, ensuring a seamless purchasing experience for clients.

2. ABB DCS800 Series DC Drive Motor

ABB's DCS800 series combines advanced motor technology with proven reliability for industrial automation needs. The brushless motor design eliminates carbon brush maintenance while providing superior performance characteristics.

Motor efficiency exceeds 92% through optimized electromagnetic field design and premium materials. This efficiency level significantly reduces energy consumption over the motor's operational lifetime. The variable speed capability ranges from zero to maximum rated speed with precise control.

Torque output remains constant across wide speed ranges, essential for applications requiring consistent performance. The motor cooling system utilizes advanced heat dissipation techniques to maintain optimal operating temperatures. Thermal protection prevents damage from overload conditions.

The motor housing features IP55 protection rating, suitable for dusty and wet industrial environments. Vibration resistance exceeds industry standards, ensuring stable operation in demanding applications.

3. Siemens SIMOREG DC-MASTER Series

Siemens SIMOREG DC-MASTER motors deliver exceptional performance for process control applications. The motor efficiency rating of 91% provides excellent energy consumption characteristics while maintaining robust operational capabilities.

Advanced armature winding technology ensures optimal current distribution and heat management. The electromagnetic field design produces smooth torque output essential for precision applications. Speed regulation accuracy reaches ±0.1% of rated speed.

Motor cooling incorporates intelligent thermal management systems that adapt to load conditions. This feature extends motor life while maintaining consistent performance. The motor housing utilizes corrosion-resistant materials for longevity.

Load capacity handling excels in both constant torque and variable torque applications. The direct current characteristics provide excellent dynamic response for rapid speed changes. Motor shaft options include various configurations for different coupling requirements.

4. WEG DC Motor W22 Series

WEG's W22 series DC motors combine cost-effectiveness with reliable performance for diverse industrial applications. Motor efficiency reaches 90.2% through optimized design and quality materials, reducing operational costs.

The robust motor housing withstands challenging industrial environments while maintaining precise mechanical tolerances. Torque output characteristics suit both starting and running requirements across various applications. Variable speed control provides excellent flexibility.

Electromagnetic field optimization ensures smooth operation and reduced electromagnetic interference. The armature winding utilizes premium insulation materials for extended service life. Motor cooling design maintains optimal temperatures during continuous operation.

Speed regulation capabilities accommodate demanding process control requirements. The motor controller compatibility enables sophisticated automation systems. Direct current characteristics provide excellent controllability for precision applications.

5. Marathon Electric DC Motor Series

Marathon Electric DC motors provide dependable performance for industrial automation and process control applications. Motor efficiency of 89% delivers good energy consumption characteristics while maintaining affordability.

The motor housing construction utilizes durable materials suitable for industrial environments. Torque output remains consistent across operational speed ranges, essential for reliable performance. The electromagnetic field design minimizes vibration and noise.

Armature winding technology ensures optimal current flow and heat dissipation. Motor cooling systems maintain appropriate operating temperatures during extended operation periods. The brushless motor options eliminate maintenance requirements associated with carbon brushes.

Variable speed capabilities accommodate diverse application requirements. Speed regulation accuracy meets industrial standards for process control applications. The motor controller integration provides flexible automation possibilities.

6. Baldor-Reliance CDP3584 Series DC Motor

The Baldor-Reliance CDP3584 represents excellence in industrial DC motor design, delivering consistent performance across demanding applications. This motor features a robust cast iron motor housing that withstands harsh industrial environments while maintaining precise tolerances.

Key specifications include 1750 RPM base speed with excellent speed regulation capabilities. The armature winding utilizes high-grade copper conductors for optimal current flow and heat dissipation. Motor efficiency reaches 89.5%, reducing energy consumption compared to standard motors. The electromagnetic field design provides smooth torque output across the entire speed range. This characteristic makes it ideal for conveyor systems, mixing equipment, and variable speed applications. The motor cooling system incorporates forced ventilation for consistent temperature control.

Installation flexibility comes from multiple mounting configurations and motor shaft options. The standard frame size integrates easily with existing equipment. Maintenance requirements remain minimal due to quality bearing systems and robust construction.

Global Market Analysis

The global market for 20 hp dc electric motor spans diverse geographical regions with varying regulatory requirements and cultural preferences. North American markets emphasize energy efficiency standards, with NEMA regulations governing motor performance specifications.

European markets prioritize environmental compliance, requiring motors meeting strict energy consumption guidelines. The IE3 efficiency standards mandate minimum performance levels for industrial motors. Cultural preferences lean toward maintenance free designs reducing operational intervention.

Asian markets, particularly China and India, focus on cost-effectiveness while maintaining adequate performance. Local manufacturing capabilities influence availability and pricing structures. Cultural factors emphasize long-term reliability over initial purchase price considerations.

Regulatory compliance varies significantly across regions. Safety standards like IEC and UL certifications affect market acceptance. Voltage rating requirements differ between countries, influencing motor design specifications. Environmental regulations impact motor cooling and efficiency requirements.

Cultural preferences influence purchasing decisions significantly. Some regions prioritize established brand recognition, while others focus on local supplier relationships. Technical support availability affects market penetration in remote geographical areas.

Purchasing Recommendations and Considerations

Evaluate your specific application requirements before selecting a 20 hp DC motor. Consider torque output needs, speed regulation requirements, and environmental conditions. Motor efficiency directly impacts long-term operational costs through energy consumption.

Budget considerations should include initial purchase price, installation costs, and ongoing operational expenses. Higher efficiency motors typically offer better lifecycle value despite higher initial costs. Maintenance requirements affect total cost of ownership significantly.

Supplier evaluation encompasses technical support capabilities, warranty coverage, and parts availability. Local service networks minimize downtime during maintenance periods. Manufacturer reputation influences long-term satisfaction and reliability expectations.

Technical specifications must match your power supply and control system requirements. Voltage rating compatibility prevents costly electrical modifications. Motor controller integration capabilities affect automation system possibilities.

Installation planning should consider mounting requirements, coupling specifications, and cooling needs. Proper motor cooling ensures optimal performance and longevity. Environmental protection ratings must match operating conditions.

Industry Trends and Summary

Industrial automation continues driving demand for efficient, controllable DC motors. Energy efficiency improvements focus on reducing operational costs and environmental impact. Brushless motor technology gains popularity through maintenance free operation benefits. Smart motor technologies enable predictive maintenance and remote monitoring capabilities. The integration of IoT sensors provides real-time performance data for optimization. Variable speed drive systems become standard for energy conservation and process control precision.

Conclusion

Selecting the best 20 hp DC electric motor for your industrial application requires careful consideration of performance specifications, environmental requirements, and long-term operational costs. The motors featured in this guide represent proven solutions across diverse industrial automation applications.

Motor efficiency, torque output characteristics, and speed regulation capabilities directly impact your operational success. Investing in quality motors from established manufacturers ensures reliable performance and comprehensive support throughout the motor's lifecycle.

Consider your specific application requirements, budget constraints, and future expansion plans when making your selection. The right motor choice provides years of dependable service while supporting your industrial automation goals effectively.

Frequently Asked Questions

Q1: What maintenance requirements do 20 hp DC motors typically have?

A: Brushed DC motors require carbon brush replacement every 1,000-2,000 operating hours, while brushless variants need minimal maintenance beyond bearing lubrication and cooling system cleaning. Regular inspection of motor housing, connections, and cooling systems ensures optimal performance.

Q2: How do I determine the right voltage rating for my application?

A: Match the motor voltage rating to your existing power supply system. Common industrial voltages include 240V, 480V, and 600V. Consult your electrical system specifications and consider power supply capacity when selecting voltage ratings.

Q3: What efficiency improvements can I expect from upgrading to a modern 20 hp DC motor?

A: Modern high-efficiency DC motors achieve 90-93% efficiency compared to 85-88% for older models. This improvement can reduce energy consumption by 5-8%, providing significant cost savings over the motor's operational lifetime.

Get Your Ideal 20 HP DC Electric Motor from XCMOTOR

XCMOTOR specializes in providing comprehensive power equipment solutions tailored to your specific industrial automation needs. Our extensive experience with 20 hp dc electric motor applications across manufacturing, HVAC, and process control industries ensures you receive expert guidance for optimal motor selection.

As a trusted 20 hp dc electric motor supplier, we maintain extensive inventory to meet urgent delivery requirements. Our technical team assists with proper motor selection based on your load capacity, voltage rating, and environmental conditions.

Ready to enhance your industrial operations with the right DC motor solution? Contact us at xcmotors@163.com to discuss your specific requirements and receive personalized recommendations from our motor specialists.