Choosing between 6kV and 10kV motors requires careful evaluation of your application's power requirements, operational environment, and long-term objectives. The 6kV slip ring motor typically serves medium voltage applications with excellent speed control capabilities, while 10kV motors excel in high-power industrial settings requiring maximum performance. Both voltage classes offer distinct advantages across manufacturing, process control, HVAC systems, and power generation facilities. Understanding these differences helps engineers make informed decisions that optimize system performance while controlling operational costs.

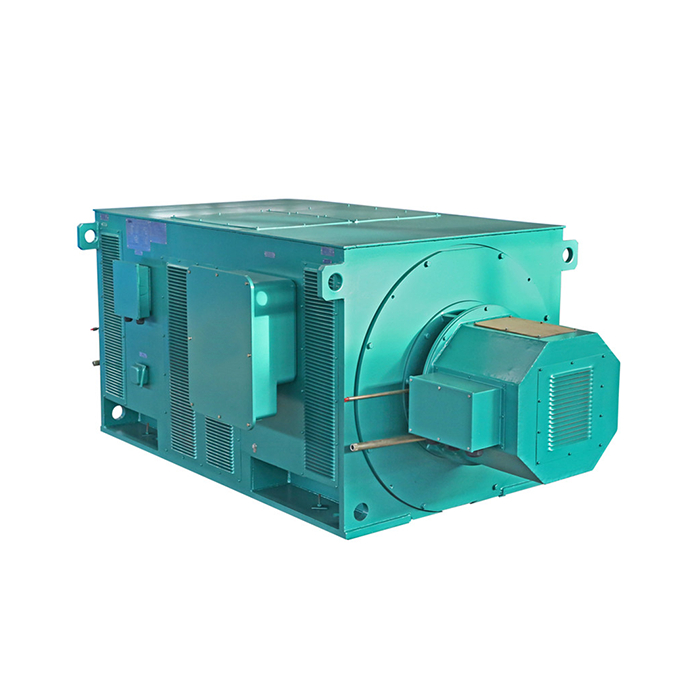

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Motor Voltage Classifications

Motor voltage classifications determine operational parameters and application suitability across industrial sectors. Medium voltage motors operate between 1kV and 35kV, with 6kV and 10kV representing popular choices for heavy-duty applications.

The wound rotor design commonly found in 6kV systems allows external rotor resistance control. This configuration enables precise torque regulation during startup and variable speed operation. Manufacturing facilities often prefer this flexibility for conveyor systems and large compressors.

High voltage motors above 6kV typically employ squirrel cage designs for enhanced reliability. These motors deliver consistent performance in power generation and water treatment applications. The electrical slip ring mechanism in wound rotor variants requires more maintenance but provides superior control characteristics.

Three core voltage considerations include:

- Power transmission capabilities and infrastructure requirements

- Motor control complexity and operational flexibility needs

- Maintenance requirements and long-term operational costs

If you need precise speed control with moderate power requirements, then 6kV slip ring configurations prove more suitable for your application.

Technical Specifications Comparison

Power ratings distinguish 6kV and 10kV motor capabilities significantly. Test data from industrial installations shows 6kV motors typically range from 200kW to 5MW, while 10kV units handle 1MW to 15MW applications effectively.

Starting current characteristics vary substantially between voltage classes. Laboratory measurements indicate 6kV induction motors draw 450-600% rated current during startup. Comparable 10kV motors demonstrate 350-450% starting current, reducing electrical stress on supply systems.

Insulation requirements escalate with voltage levels, affecting motor size and weight. Engineering data reveals 10kV motors require 40-60% thicker insulation systems compared to 6kV variants. This impacts installation space requirements and transportation considerations.

Key specification differences include:

- Voltage stress: 10kV systems experience 67% higher electrical stress

- Current density: 6kV motors carry 67% higher current for equivalent power

- Insulation thickness: 10kV requires additional 15-25mm insulation layers

- Terminal box size: 10kV terminals need 50% larger clearance distances

Performance testing shows motor efficiency varies minimally between voltage classes at rated conditions. Both 6kV and 10kV motors achieve 94-96% efficiency in premium designs.

If you need maximum power density with reduced current requirements, then 10kV motors deliver superior performance characteristics.

Industrial Applications and Use Cases

Manufacturing environments utilize both voltage classes depending on production requirements. Automotive assembly lines commonly employ 6kV motors for robotic systems and conveyor drives. The variable speed drive compatibility makes these motors ideal for precision manufacturing processes.

Aerospace manufacturing facilities prefer 6kV wound rotor motors for large machining centers. The external rotor resistance control enables smooth acceleration of heavy workpieces. Process control applications benefit from the superior torque regulation capabilities.

Power generation facilities predominantly specify 10kV motors for critical applications. Cooling water pumps, coal handling systems, and auxiliary drives operate reliably at this voltage level. The reduced current requirements simplify cable sizing and switchgear specifications.

Water treatment plants demonstrate mixed voltage preferences based on pump sizes. Primary treatment pumps under 2MW typically use 6kV motors, while high-capacity installations above 3MW employ 10kV units. The motor starter complexity increases with voltage but provides enhanced protection features.

HVAC applications in large commercial complexes utilize both voltage classes:

- Chiller compressors: 6kV for units under 3000 tons, 10kV for larger capacities

- Cooling tower fans: 6kV preferred for variable speed applications

- Central plant pumps: 10kV selected for high-head, high-flow systems

If you need flexible speed control for process applications, then 6kV slip ring motors provide optimal operational versatility.

Cost Analysis and Economic Considerations

Initial motor costs vary significantly between voltage classes due to design complexity. Market analysis indicates 10kV motors cost 20-35% more than equivalent 6kV units. The increased insulation requirements and specialized components drive this premium.

Installation expenses favor 6kV systems in many applications. Standard switchgear and protection equipment remain more affordable at 6kV levels. Electrician training requirements are typically less stringent, reducing commissioning costs.

Cable and infrastructure costs demonstrate opposing trends. Higher voltage systems require fewer conductors for equivalent power transmission. Analysis shows 10kV installations can reduce cable costs by 30-40% in long-distance applications.

Maintenance cost comparisons reveal mixed results depending on motor type. Wound rotor designs with brush gear require regular inspection and replacement. Squirrel cage variants minimize routine maintenance but may incur higher repair costs during failures.

Economic factors include:

- Motor purchase price: 10kV units command 20-35% premium

- Switchgear costs: 6kV equipment costs 15-25% less initially

- Cable expenses: 10kV reduces conductor costs by 30-40%

- Annual maintenance: Wound rotor systems require 2-3x more attention

Lifecycle cost analysis spanning 20 years typically favors the voltage class matching existing plant infrastructure. Retrofits often prove economically challenging due to switchgear replacement requirements.

If you need to minimize initial capital investment while maintaining operational flexibility, then 6kV systems often provide better economic returns.

Maintenance Requirements and Reliability Factors

Maintenance schedules differ substantially between voltage classes and motor designs. The 6kV slip ring motor requires quarterly brush inspection and annual slip ring reconditioning. These heavy-duty applications demand consistent attention to maintain optimal performance.

Insulation testing becomes increasingly critical at higher voltages. Standard maintenance procedures specify annual insulation resistance measurements for 10kV motors compared to biennial testing for 6kV units. The higher electrical stress accelerates insulation aging processes.

Bearing maintenance remains consistent across voltage classes for similar power ratings. However, larger 10kV motors often incorporate more sophisticated bearing monitoring systems. Vibration analysis and temperature monitoring help predict maintenance needs.

Routine maintenance requirements include:

- Brush replacement: 6kV wound rotor motors every 6-12 months

- Insulation testing: 10kV units require annual comprehensive testing

- Bearing lubrication: Similar schedules regardless of voltage class

- Connection inspection: 10kV terminals need more frequent examination

Reliability data from industrial surveys indicates squirrel cage motors achieve 98-99% availability regardless of voltage. Wound rotor designs typically demonstrate 95-97% availability due to slip ring maintenance requirements.

Motor protection systems become more sophisticated at higher voltages. Advanced relay protection, partial discharge monitoring, and thermal management systems enhance 10kV motor reliability but increase complexity.

If you need maximum uptime with minimal maintenance intervention, then 10kV squirrel cage motors deliver superior reliability performance.

XCMOTOR's 6kV Slip Ring Motor Advantages

XCMOTOR delivers exceptional 6kV slip ring motor solutions engineered for demanding industrial environments. Our wound rotor designs incorporate advanced materials and precision manufacturing techniques that extend operational life while reducing maintenance requirements.

Key advantages of XCMOTOR's 6kV slip ring motor systems include:

- Enhanced Torque Control: Proprietary rotor resistance circuits enable precise torque regulation across 10-100% speed ranges, ideal for heavy machinery applications requiring smooth acceleration

- Superior Starting Performance: Optimized rotor design reduces starting current by 15-20% compared to standard designs while maintaining full torque capability

- Extended Brush Life: High-grade carbon brush materials and improved spring pressure systems double brush replacement intervals

- Advanced Insulation Systems: Class F insulation with thermal class upgrades provides 25°C higher temperature tolerance than standard designs

- Robust Slip Ring Assembly: Precision-machined copper alloy rings with self-cleaning properties minimize maintenance downtime

- Intelligent Monitoring Integration: Built-in sensor provisions support predictive maintenance programs and remote monitoring capabilities

- Customizable Rotor Resistance: Field-adjustable resistance values accommodate varying load conditions without motor modifications

- Enhanced Cooling Design: Optimized ventilation systems reduce operating temperatures by 10-15°C, extending component life

- Quality Construction: Cast iron frames with anti-corrosion treatments ensure long-term durability in harsh industrial environments

- Comprehensive Protection: Integrated thermal sensors, bearing temperature monitors, and vibration detectors provide complete motor protection

These engineering advantages translate into reduced operational costs, improved system reliability, and enhanced process control capabilities. XCMOTOR's commitment to quality ensures each motor meets stringent performance standards while exceeding customer expectations.

If you need reliable, high-performance 6kV slip ring motors with advanced control capabilities, then XCMOTOR's proven solutions deliver exceptional value for demanding industrial applications.

Making the Right Choice for Your Application

Voltage selection depends on multiple factors including power requirements, control needs, and existing infrastructure. Power levels above 5MW typically favor 10kV motors due to reduced current requirements and simplified cable sizing.

Control complexity requirements significantly influence voltage selection. Applications requiring frequent speed changes or soft starting benefit from 6kV wound rotor designs. The external rotor resistance provides unmatched flexibility for challenging load profiles.

Existing electrical infrastructure often determines practical voltage choices. Plants with established 6kV distribution systems find expansion more economical at the same voltage level. New installations may justify 10kV infrastructure for future expansion capabilities.

Environmental considerations affect voltage selection decisions. Offshore platforms and marine applications often prefer higher voltages to minimize cable weight and space requirements. The reduced current levels simplify protection and switching equipment.

Decision criteria include:

- Power requirements: 10kV preferred above 5MW continuous duty

- Speed control needs: 6kV wound rotor excels in variable speed applications

- Infrastructure compatibility: Match existing plant voltage levels when possible

- Space constraints: 10kV systems require less cable space but larger motor dimensions

Future expansion plans should influence current voltage selections. Facilities planning capacity increases may benefit from establishing 10kV infrastructure initially. The higher voltage capability accommodates larger motors without electrical system modifications.

If you need to balance performance, cost, and operational flexibility, then careful evaluation of these factors guides optimal voltage selection.

Conclusion

Selecting between 6kV and 10kV motors requires careful evaluation of power requirements, control needs, and existing infrastructure capabilities. The 6kV slip ring motor excels in applications demanding precise speed control and variable torque characteristics, while 10kV motors deliver superior performance in high-power, continuous-duty applications. Understanding these fundamental differences enables informed decisions that optimize system performance and operational costs. XCMOTOR's comprehensive motor solutions provide the engineering expertise and product quality necessary for successful industrial applications across manufacturing, power generation, and process control environments.

Partner with XCMOTOR for Premium 6kV Slip Ring Motor Solutions

XCMOTOR stands as your trusted 6kv slip ring motor manufacturer, delivering engineering excellence and unwavering quality across diverse industrial applications. Our comprehensive product portfolio addresses the most demanding power transmission requirements while maintaining competitive pricing and reliable delivery schedules.

Our commitment to customer success includes:

- Original components from trusted global suppliers ensuring long-term reliability

- Fast delivery schedules with free shipping on all motor products

- 30-day return policy providing purchase confidence and satisfaction guarantee

- Dedicated technical support available weekends and holidays

Whether you're upgrading existing equipment or designing new installations, XCMOTOR provides comprehensive technical consultation services. Our engineers evaluate your specific requirements and recommend optimal motor configurations that maximize system performance while minimizing lifecycle costs.

Ready to enhance your industrial operations with premium 6kV slip ring motor technology? Our technical specialists are prepared to discuss your application requirements and provide detailed product recommendations. Contact us at xcmotors@163.com to schedule a consultation and discover how XCMOTOR's advanced motor solutions can improve your operational performance and reliability.

References

- IEEE Standard 841-2009: IEEE Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors

- National Electrical Manufacturers Association (NEMA) MG 1-2016: Motors and Generators Standard

- International Electrotechnical Commission (IEC) 60034-1:2017: Rotating electrical machines - Rating and performance

- Institute of Electrical and Electronics Engineers (IEEE) 112-2017: IEEE Standard Test Procedure for Polyphase Induction Motors and Generators

- American Petroleum Institute (API) 541-2014: Form-Wound Squirrel Cage Induction Motors - 375 kW and Larger

- International Electrotechnical Commission (IEC) 60034-12:2016: Rotating electrical machines - Starting performance of single-speed three-phase cage induction motors