When motors break down unexpectedly in an industrial setting, it may have a huge effect on production and profits. Slip ring rotor motors are strong and useful, but you need to know how to use and care for them properly to get the most out of them. These wound-rotor motors are very important for manufacturing, power generation, and automation systems. For business to keep running, they must work reliably.

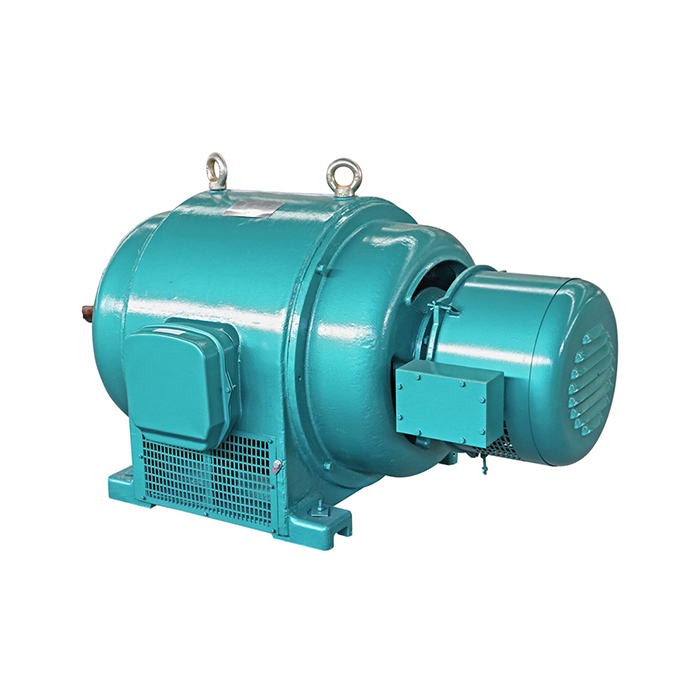

Series:YRQ

Voltage range:380V±5%

Power range:45-710kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What You Need to Know About Slip Ring Rotor Motors

What does a slip ring rotor motor do?

A slip ring rotor motor, which is sometimes called a wound-rotor motor, is a specific kind of induction motor that is made for jobs that need very fine control and very high beginning torque. These motors are different from regular squirrel cage motors in that their exterior rotor windings are coupled to variable resistance circuits using slip rings and brushes.

The main parts are the stator housing, the rotor assembly with windings, slip rings, carbon brushes, and controls for external resistance. This setup lets operators change the motor's speed-torque characteristics by changing the external resistance. This gives industrial applications unprecedented versatility. The slip rings connect the rotor windings to make a full electrical circuit. This lets electricity flow continuously when the rotor is turning.

What is the function of a slip ring rotor motor?

The basic idea behind how it works is electromagnetic induction between the stator and rotor windings. When AC power flows through the stator, it generates a magnetic field that turns the rotor windings. The slip rings maintain the electrical connection with the rotor circuit while letting it keep spinning.

When the motor starts up, a lot of external resistance is added to the rotor circuit. This minimizes the inrush current and increases the beginning torque. As the motor speeds up, operators slowly lower this resistance so that the motor can attain its rated speed. These motors are great for heavy-duty jobs that need regulated starting characteristics because this procedure makes acceleration smooth and keeps the power supply from getting too much electrical stress.

Common Problems with Slip Ring Rotor Motors Problems with the Efficiency of Slip Ring Rotor Motors

Slip ring rotor motors usually lose performance because of a number of reasons that are all interrelated and impact the efficiency of the whole system. Knowing about these problems makes it possible to do maintenance before anything goes wrong and get the best performance back.

Brush wear, slip ring contamination, and wrong resistance settings are the main reasons for loss of efficiency. When carbon brushes wear out, they don't make good electrical contact, which causes voltage dips and more heat to be produced. Oil, dust, or carbon deposits may make slip rings dirty, which makes electrical conductivity even worse.

Here are the main ways to fix issues with efficiency:

- Check and replace brushes regularly: Check how much wear the brushes are getting every three months in normal circumstances or every month in tough situations. To maintain the best contact pressure and electrical conductivity, change brushes when they wear down to half of their original length.

- Cleaning and taking care of slip rings: Use the right solvents and fine abrasives to clean slip rings and get rid of dirt. A good surface polish makes sure that the brush makes contact evenly and lowers the electrical resistance at the connection interface.

- Calibrating resistance: Check that the external resistance settings are in line with what is needed for the job. If the resistance values are wrong, there might be too much slip, which means more rotor losses and less efficiency over the whole working range.

These maintenance tasks may bring motor efficiency back to within 95% of nameplate ratings, which greatly lowers operating costs and extends the life of equipment in industrial settings.

Fixing problems with maintaining a slip ring rotor motor

Preventive maintenance plans are very important for keeping motors running smoothly and avoiding unexpected breakdowns. To fully preserve the system, regular maintenance programs should include both electrical and mechanical parts.

Brush alignment difficulties, slide ring grooving, bearing wear, and loose connections are all common concerns that come up during maintenance. These problems generally become worse with time, so it's important to catch them early to avoid major failures that might stop production.

The following maintenance checklist lists important places to check:

- Check every week for strange noises, vibrations, or overheating. Keep an eye on the brush spark patterns and the quality of the slip ring surface. Too much sparking means that there are alignment problems or pollution that has to be fixed right away to stop the damage from becoming worse.

- Testing the electrical system every month: Check the insulation resistance, winding continuity, and contact resistance across the slip rings. Values that are outside of what the manufacturer says are normal show that issues are starting to happen and need to be fixed before they become worse.

- Every three months, mechanical maintenance: Check the torque requirements for the mounting bolts, lubricate the bearings, and check the alignment of the connection. To maintain the best electrical contact over the whole running cycle, change out worn brushes and clean the slip ring surfaces.

Following these maintenance guidelines may cut down on unexpected downtime by as much as 80%, and in tough industrial settings, they can even make motors last longer than the manufacturer expected.

Uses for Slip Ring Rotor Motors in Industry

Wound-rotor motors are used by manufacturing companies for important tasks that need precise control and strong beginning torque. These motors power machinery used in mining, cement manufacturing, steel mills, and systems for moving materials.

To start processing materials in cement plants, big ball mills and crushers need a lot of beginning torque to get past static friction. The regulated starting characteristics stop mechanical stress and prevent the power system from using too much electricity. Mining companies use these motors to start conveyors, crushers, and processing equipment that are already under load.

Power plants use wound-rotor motors to run extra equipment including coal pulverizers, forced draft fans, and boiler feed pumps. They are useful in power plants when there are limits on how much current may be used to start huge loads.

Applications for Specific Purposes

Wound-rotor technology is used for more than just standard industrial purposes. It is also used in specialty applications that need distinct performance characteristics. Slip ring technology is commonly used in wind turbine generators to maintain electrical connections while allowing for blade pitch adjustment and nacelle rotation.

Wound-rotor designs provide variable speed capabilities and strong beginning torque, which are useful for marine propulsion systems. For large ships to move about, they need to be able to adjust their speed very precisely while yet having enough torque to handle rough seas. These motors are good for tough maritime settings since they are built to last and can be controlled.

Things to Think About When Buying a Slip Ring Rotor Motor

To choose the right wound-rotor motors, you need to carefully think about the needs of the application, the circumstances of the environment, and the performance requirements. The decision-making process should take into account both the startup costs and the ongoing costs of running the business.

Power rating, voltage requirements, speed range, and beginning torque required are all important criteria. The protection class requirements and choice of materials are affected by things like temperature, humidity, and degrees of contamination. The total cost of ownership during the life of the motor is also affected by how easy it is to get replacement parts and technical help.

Top Suppliers and Makers

ABB, Siemens, and General Electric are all well-known manufacturers in the worldwide market. Each has its own strengths in technology and support. Siemens focuses on dependability and standards, whereas ABB focuses on energy efficiency and digital integration. General Electric offers full industrial solutions with a wide range of service networks.

Regional vendors typically provide quicker delivery and more specific options for standard ratings. Choosing between global and regional suppliers relies on the technical demands, delivery times, and continuing support needs of certain applications.

XCMOTOR: Your Reliable Partner for Slip Ring Rotor Motors

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. (XCMOTOR) is a top maker of high-quality slip ring rotor motors that are designed for tough industrial uses. Our dedication to quality guarantees that our products will work well in a variety of situations.

Our YRQ(JR) series medium-sized motors are very flexible and can work with power levels from 45kW to 800kW at an operating voltage of 380V±5%. These motors have an IP23 protection grade and use high-quality SKF, NSK, or FAG bearings, depending on what the client needs. The strong structure lets it work in tough conditions while keeping up a steady level of performance over long periods of time.

XCMOTOR uses modern production methods including precision winding and vacuum pressure impregnation (VPI) to make insulation last longer. Before we ship out any motors, our thorough quality check makes sure that they all fulfill strict performance criteria. Our motors are perfect for heavy-duty jobs like crushers, mills, pumps, and transportation apparatus because they can start with a lot of torque (up to 280% of rated torque) and a low beginning current.

Conclusion

To run a wound-rotor motor well, you need to know about typical problems and use proactive maintenance methods. Slip ring technology has several unique benefits, such as strong beginning torque and the ability to adjust speed, which make these motors very useful for tough industrial jobs. Regular maintenance, good troubleshooting skills, and high-quality equipment from well-known companies like XCMOTOR all help make sure that things work well and get the most out of your money. Industrial operations may get the most work done while spending the least amount of money on operations by fixing issues with efficiency, maintenance, and application-specific needs.

Questions that are often asked

Q1: What are the primary benefits of employing wound-rotor motors instead of ordinary induction motors?

A: Compared to traditional squirrel cage designs, wound-rotor motors have better beginning torque, speed control, and lower starting current. They work well in situations when you need a lot of beginning torque and the ability to change speeds without adding more electrical controls.

Q2: How frequently should you check on the slip ring?

A: Under normal circumstances, brush inspections should happen once a month, and brushes should be replaced every 6 to 12 months, depending on how the machine is used. Cleaning the slip ring should be done every three months, and more often in places where there is dirt.

Q3: Is it possible for wound-rotor motors to work with variable frequency drives?

A: Yes, contemporary wound-rotor motors may work with VFDs to improve speed control and save energy. But for the best performance, the VFD and rotor resistance control must work together properly.

Q4: What makes the slip rings ignite too much?

A: Bad brush contact, dirty slip rings, too much brush pressure, or misalignment are all common causes of too much sparking. Most sparking problems may be fixed with regular maintenance and precise adjustments, which also prevents equipment from becoming damaged.

Partner with XCMOTOR for Reliable Slip Ring Rotor Motor Solutions

Industrial operations need motor solutions that are dependable, efficient, and can keep working well even when things become tough. XCMOTOR's knowledge in designing and making wound-rotor motors gives them the technological know-how to make industrial applications work. We have a wide selection of products that can meet power needs from 45kW to 800kW. These products may be used in a variety of sectors, including mining, manufacturing, power generating, and processing.

We are a top slip ring rotor motor manufacturer, and we know how important it is for industrial equipment to work reliably. Our engineers work closely with clients to figure out the best motor combinations for each application, making sure that the motors run at their best and last as long as possible. Using high-quality materials, innovative production methods, and strict testing procedures ensures that it will work reliably under the most difficult conditions.

Want to improve your industrial operations using high-quality slip ring rotor motor technology? Get in touch with our technical experts to talk about your needs and find out how XCMOTOR's solutions may help you run your business more efficiently. For more information about our products and technical assistance, please email us at xcmotors@163.com.