The oil and gas industry operates in some of the world's most challenging environments where safety cannot be compromised. Explosive atmospheres containing hydrocarbons, volatile organic compounds, and combustible gases demand specialized equipment that meets stringent safety requirements. Standard motors pose significant risks in these environments, as internal sparks or excessive heat generation can trigger catastrophic explosions. Modern YBX5 explosion-proof motors utilize sophisticated engineering principles including flame path management, temperature control, and pressure containment. Their specialized construction involves precision machining, high-quality materials, and rigorous testing protocols. The resulting equipment provides reliable operation while maintaining the highest safety standards required for oil and gas applications.

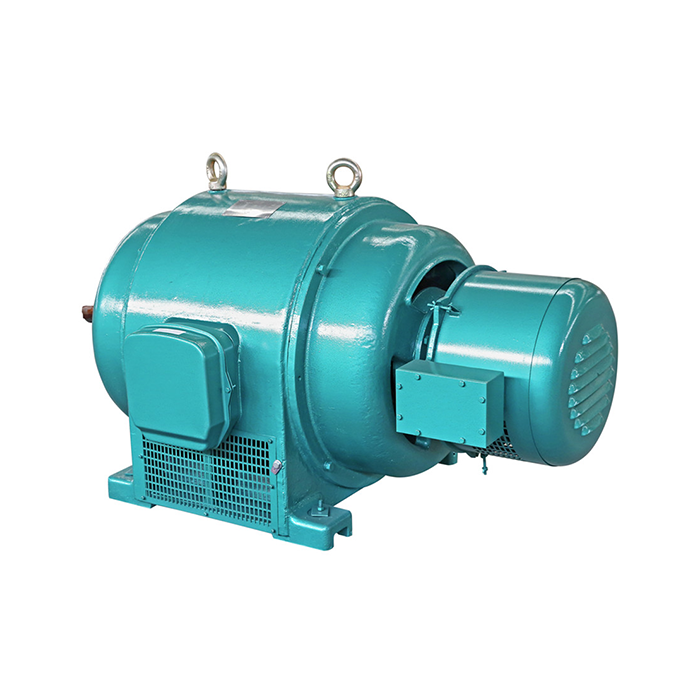

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Why Focus on YBX5 Explosion-Proof Motors

The petroleum industry's increasing complexity demands motors that exceed traditional performance boundaries while maintaining uncompromising safety standards. Modern drilling operations, refinement processes, and distribution systems require equipment capable of operating continuously in extreme conditions. Traditional motors simply cannot meet these demanding requirements without posing significant safety risks.

YBX5 explosion-proof motors address these challenges through innovative design features and advanced manufacturing techniques. Their fully enclosed, self-fan cooling systems ensure optimal temperature management during extended operation periods. The squirrel cage design provides exceptional torque characteristics while maintaining mechanical simplicity for reduced maintenance requirements.

Global regulatory frameworks increasingly emphasize equipment certification and compliance verification. The YBX5 series meets international standards including ATEX directives and IECEx schemes, ensuring worldwide acceptance and regulatory compliance. This standardization reduces procurement complexity while guaranteeing consistent performance across different geographical markets.

Selection Criteria for Best YBX5 Motors

Selecting optimal explosion-proof motors requires careful evaluation of multiple technical and operational factors. Our assessment methodology prioritizes safety certification, performance characteristics, reliability metrics, and application suitability. Each motor undergoes comprehensive analysis based on real-world performance data and customer feedback from global installations.

Safety certification represents the fundamental selection criterion, with motors evaluated against international explosion-proof standards. We examine certification scope, testing protocols, and compliance verification procedures. Performance analysis includes power density, torque characteristics, starting capabilities, and thermal management effectiveness under various operating conditions.

Reliability assessment encompasses bearing quality, insulation systems, environmental resistance, and maintenance requirements. We evaluate customer testimonials, field performance data, and manufacturer support capabilities. Cost-effectiveness analysis considers initial investment, operational costs, maintenance expenses, and lifecycle value proposition.

Application suitability evaluation examines motor compatibility with specific industry requirements including mounting configurations, environmental conditions, control system integration, and regulatory compliance needs. This comprehensive approach ensures recommended motors deliver optimal performance for intended applications.

Top 5 YBX5 Explosion-Proof Motors

1. YBX5-160L-4 37kW Explosion-Proof Motor

This mid-range powerhouse delivers exceptional performance for moderate-duty applications in petrochemical facilities and offshore platforms. The 37kW power output provides adequate torque for pumping systems, conveyor drives, and processing equipment. Its 380V/660V dual voltage capability offers installation flexibility across different electrical systems.

- Cast iron frame construction ensures mechanical durability and excellent heat dissipation

- IP55 protection degree guards against dust ingress and water spray

- F-class insulation system withstands temperatures up to 155°C

- Ex d IIB T4 Gb certification for Zone 1 hazardous areas

- SKF premium bearings provide extended service life

- DOL and star-delta starting options accommodate various control requirements

The dual voltage design eliminates the need for custom transformers in many installations, reducing system complexity and costs. Advanced winding techniques provide excellent starting torque while minimizing inrush current. This combination makes the motor ideal for applications requiring frequent starts and variable load conditions.

2. YBX5-280S-6 75kW Heavy-Duty Motor

Engineered for demanding applications requiring high torque at moderate speeds, this 75kW motor excels in heavy-duty pumping and compression systems. The six-pole design delivers superior torque characteristics while maintaining efficient operation. Its larger frame accommodates enhanced cooling systems and heavy-duty bearings.

- Enhanced cooling system manages heat generation during continuous operation

- Heavy-duty cast iron construction withstands harsh industrial environments

- Low-speed, high-torque characteristics suit pumping applications

- Ex d IIC T4 Gb certification for highest risk gas groups

- NSK precision bearings ensure smooth operation and longevity

- Reinforced mounting feet accommodate high-vibration installations

- Advanced insulation system provides superior electrical protection

- Multiple voltage configurations support diverse electrical systems

The motor's robust bearing system accommodates axial and radial loads from coupled pumps and compressors. Precision balancing minimizes vibration transmission to connected equipment and mounting structures. These features contribute to reduced maintenance costs and extended system lifecycle.

3. YBX5-315M-4 132kW High-Performance Motor

This high-performance motor targets applications demanding substantial power output with precise control capabilities. The 132kW rating suits large pumping systems, compressors, and processing equipment in major petrochemical facilities. Advanced design features ensure reliable operation under the most demanding conditions.

- High power density maximizes performance while minimizing footprint

- Advanced cooling system maintains optimal temperatures during peak loads

- Precision-machined components ensure smooth operation and longevity

- Multiple starting methods accommodate various control system requirements

- FAG premium bearings provide exceptional load capacity and durability

- Reinforced frame construction withstands high-stress applications

- Ex d IIB T4 Gb certification ensures safety in hazardous environments

- Flexible mounting options accommodate diverse installation requirements

Installation data from major refineries shows this motor consistently delivers rated performance while maintaining safety standards. The high power density design reduces installation space requirements, particularly valuable in crowded process areas. Advanced thermal management prevents overheating during sustained high-load operation.

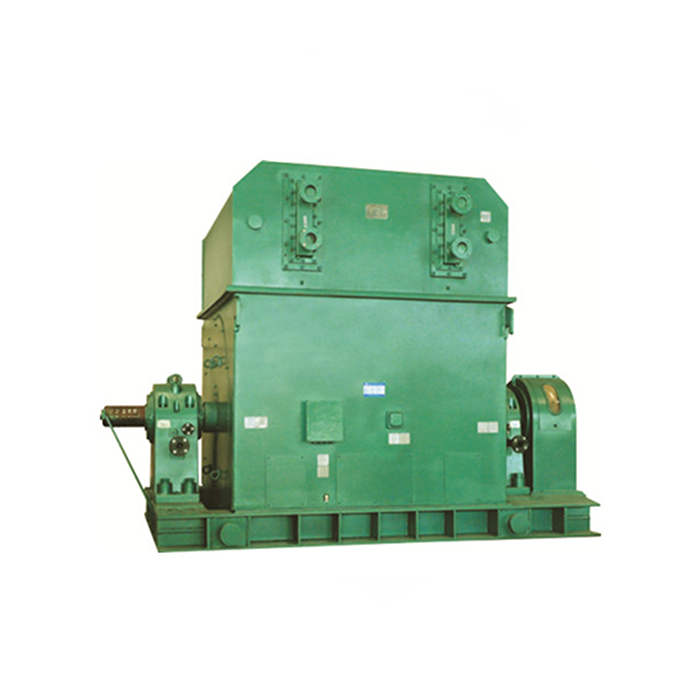

4. YBX5-355L-6 250kW Industrial Workhorse

Designed for heavy industrial applications, this 250kW motor represents the pinnacle of explosion-proof motor engineering. Its substantial power output drives large-scale equipment including main oil pumps, primary compressors, and major processing systems. The six-pole configuration delivers exceptional torque at moderate speeds.

- Massive power output handles the most demanding industrial applications

- Six-pole design provides superior starting torque and speed control

- Enhanced structural design accommodates high mechanical stresses

- Advanced cooling system manages substantial heat generation

- Premium bearing systems handle extreme radial and axial loads

- Multiple voltage options support various electrical infrastructures

- Ex d IIC T4 Gb certification for maximum safety assurance

The motor's modular design philosophy simplifies maintenance procedures and reduces downtime. Easily accessible components enable routine servicing without complete motor removal. This design approach significantly reduces maintenance costs and operational disruption in critical process applications.

5. YBX5-400L-8 315kW Ultimate Power Solution

This flagship motor represents the ultimate in explosion-proof motor technology, delivering massive power output for the most critical applications. The 315kW rating drives major compressor stations, primary processing equipment, and large-scale pumping systems. Eight-pole design provides maximum torque density and precise speed control.

- Maximum power output for critical large-scale applications

- Eight-pole configuration delivers exceptional torque characteristics

- Advanced thermal management system handles extreme heat loads

- Reinforced construction withstands the highest mechanical stresses

- Premium bearing package accommodates massive operational loads

- Comprehensive monitoring capabilities support predictive maintenance

The motor's sophisticated design accommodates custom configuration requirements for specialized applications. Flexible mounting options and connection arrangements support diverse installation scenarios. This adaptability makes the motor suitable for both new installations and retrofit applications in existing facilities.

Purchasing Recommendations and Considerations

Application requirements, ambient circumstances, and long-term operating factors must be considered while buying explosion-proof motors. First, analyze process needs such power, speed, torque, and duty cycle. Environmental variables including temperature, humidity, and chemical exposure affect motor selection.

Certification must meet local and industry standards. Check motor certificates for installation zones. Consider expansion plans and application modifications that may alter motor needs. Standards across facilities simplify maintenance and save spare components.

Evaluation of suppliers should include technical capability, support services, and long-term sustainability. Local service availability greatly affects response times and maintenance costs. Warranty and replacement part availability impact ownership costs. Technical paperwork and training aid installation and maintenance. A complete cost study must include purchasing, installation, operating, and maintenance costs. Motor lifetime running costs depend on energy efficiency. Maintenance expenses and production continuity depend on reliability. Consider these variables while choosing motors and suppliers.

Conclusion

Explosion-proof motors effect safety, performance, and cost. The YBX5 explosion-proof motor is dependable due to advanced engineering, testing, and certification. These motors work well in demanding oil and gas applications due to their strong construction and innovative features.

We have motors for moderate-duty pumping systems and big industrial compressors. Each motor meets safety and reliability standards with unique features. Understanding application and environment helps choose motors for long-term value. Buy superior explosion-proof motors for safety, reliability, and minimal maintenance. Established technology like the YBX5 series supports current operations and anticipates future demands. Choose motors with proven performance and extended support for optimal operation.

Frequently Asked Questions

Q1: What makes YBX5 motors suitable for oil and gas applications?

A: YBX5 explosion-proof motors feature specialized enclosures that prevent internal sparks from igniting external flammable atmospheres. Their Ex d certification, robust construction, and advanced cooling systems ensure safe operation in hazardous environments containing hydrocarbons and volatile compounds.

Q2: How do I determine the correct motor size for my application?

A: Motor sizing requires analysis of load characteristics, operating conditions, and performance requirements. Consider factors including required torque, duty cycle, ambient temperature, and starting conditions. Our engineering team provides application analysis and sizing recommendations based on your specific requirements.

Q3: What maintenance is required for YBX5 explosion-proof motors?

A: Regular maintenance includes bearing lubrication, insulation testing, and enclosure inspection. The frequency depends on operating conditions and duty cycle. Premium bearings and robust construction minimize maintenance requirements while ensuring long service life. Comprehensive maintenance documentation supports optimal care practices.

Get Your YBX5 Explosion-Proof Motor from Leading Manufacturer XCMOTOR

XCMOTOR provides YBX5 explosion-proof motors with decades of expertise and support. Aside from product delivery, we aim for client happiness throughout motor life. Shaanxi Qihe Xicheng Electromechanical Equipment Co.,Ltd. provides energy-efficient, low-energy, and reliable power equipment. As a reliable YBX5 explosion-proof motor supplier, professional engineers assist with motor selection, application analysis, and installation. We provide a wide range of genuine parts from reliable manufacturers to deliver products swiftly. The 30-day return policy reflects our dedication to product quality and customer satisfaction. Weekend support ensures prompt assistance.

Quality assurance encompasses rigorous testing, genuine parts sourcing, and comprehensive documentation. Our motors undergo stringent quality control checks and performance testing under simulated hazardous conditions. When you're ready to enhance your operation with reliable explosion-proof motors, contact us at xcmotors@163.com to discuss your specific requirements and receive personalized recommendations.