OEM Supply Guide for Bulk 4000 kW Motors

In the realm of industrial power, 4000 kW motors play a crucial role in driving large-scale operations. For businesses seeking to procure these powerful machines in bulk, understanding the OEM supply process is essential. This comprehensive guide will walk you through the intricacies of sourcing and partnering with OEM suppliers for high-capacity motors, ensuring you make informed decisions that align with your operational needs.

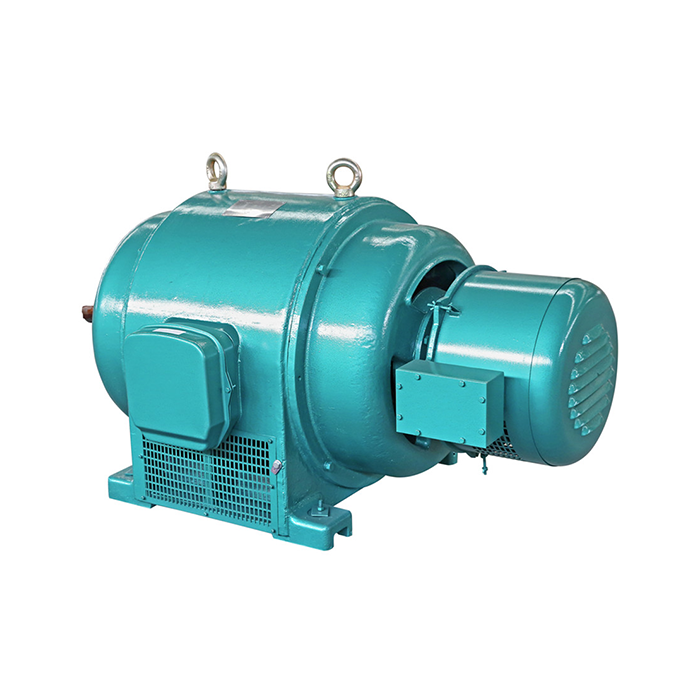

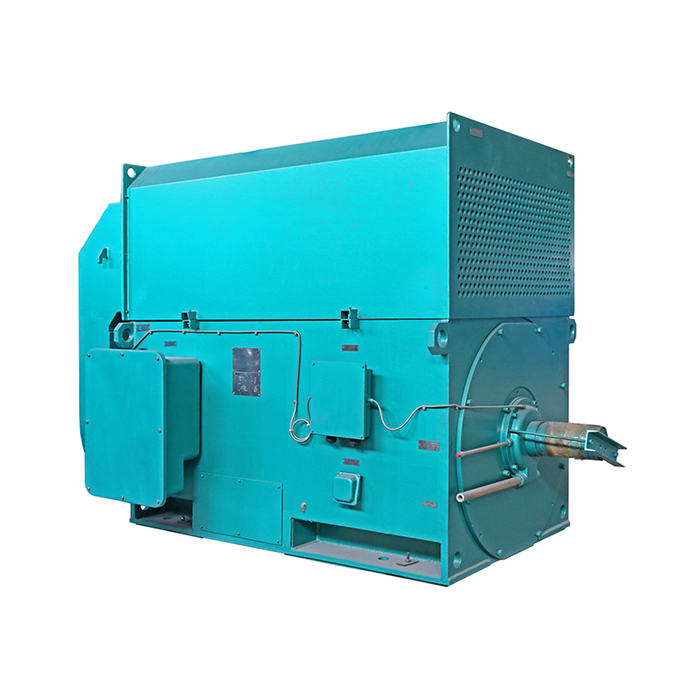

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What Steps are Involved in the Custom OEM Process for Large Industrial Motors?

The custom OEM prepare for huge mechanical engines, such as 4000 kw motors, includes a few basic steps to guarantee the last item meets particular requirements and benchmarks. Let's investigate these steps in detail:

Initial Consultation and Requirement Gathering

The handle starts with a exhaustive interview between the client and the OEM provider. Amid this stage, the client traces their particular needs, counting control yield, operational environment, and any one of a kind highlights required. The OEM supplier's building group works closely with the client to get it these prerequisites and interpret them into specialized specifications.

Design and Engineering

Once the prerequisites are clear, the OEM's plan group makes nitty gritty diagrams and 3D models of the engine. This arrange includes complex calculations to optimize execution, proficiency, and toughness. The plan handle may include a few cycles, with consistent input between the client and the OEM to refine the motor's specifications.

Prototype Development and Testing

After the plan is finalized, a model of the 4000 kw motor is built. This model experiences thorough testing to guarantee it meets the indicated execution criteria. Tests may incorporate stack testing, warm examination, and toughness appraisals. The comes about of these tests are carefully analyzed, and any fundamental alterations are made to the design.

Manufacturing and Quality Control

Once the model is affirmed, full-scale fabrication starts. The OEM provider executes strict quality control measures all through the generation handle. Each component is reviewed for exactness and quality, and get together is carried out under controlled conditions to keep up consistency over all units.

Final Testing and Certification

Before conveyance, each 4000 kw motor undergoes the last testing to confirm its execution and security. This incorporates electrical security tests, stack tests, and proficiency estimations. The engines are at that point certified to meet significant industry guidelines and regulations.

Packaging and Shipping

The last step includes carefully bundling the engines to ensure them amid transportation. For bulk orders, coordinations are facilitated to guarantee convenient and secure conveyance to the client's indicated location.

Key Considerations for Technical Requirements, Drawings, and Prototype Development

When setting out on an OEM venture for 4000 kw motors, a few key considerations must be tended to to guarantee the victory of the endeavor. These contemplations span specialized prerequisites, drawing determinations, and the model advancement process.

Technical Requirements

Defining precise technical requirements is crucial for the development of high-performance 4000 kW motors. Key aspects to consider include:

- Power output and efficiency ratings

- Operational voltage and current specifications

- Speed and torque requirements

- Cooling system specifications

- Environmental factors (temperature range, humidity, altitude)

- Insulation class and protection ratings

- Bearing type and lubrication requirements

- Noise and vibration limits

Each of these factors must be carefully considered and specified to ensure the motor meets the intended application's demands.

Drawing Specifications

Accurate and detailed drawings are essential for the successful production of 4000 kW motors. The drawing package should include:

- Detailed 2D and 3D CAD drawings

- Cross-sectional views highlighting internal components

- Electrical schematics and wiring diagrams

- Material specifications for each component

- Tolerance specifications for critical dimensions

- Assembly instructions and exploded views

These drawings serve as the blueprint for manufacturing and should be comprehensive enough to guide the production process without ambiguity.

Prototype Development

The model improvement stage is basic in approving the plan and identifying any potential issues some time recently full-scale generation. Key contemplations include:

- Selection of materials that accurately represent the final product

- Fabrication methods that closely mimic production processes

- Instrumentation for data collection during testing

- Design of test protocols to validate performance criteria

- Iterative refinement based on test results

The model ought to be a reliable representation of the planning last item, permitting for careful assessment and optimization.

Evaluating OEM Manufacturer Capabilities: Testing Facilities and Quality Assurance

When selecting an OEM manufacturer for 4000 kW motors, it's crucial to evaluate their testing facilities and quality assurance processes. These aspects are fundamental in ensuring the reliability and performance of the final product.

Advanced Testing Facilities

A reputable OEM should possess state-of-the-art testing facilities capable of rigorously evaluating high-power motors. Look for the following capabilities:

- High-power dynamometers for full-load testing

- Thermal imaging hardware for warm dissemination analysis

- Vibration examination devices to evaluate mechanical stability

- Electrical testing gear for cover and control quality

- Environmental chambers for reenacting different operational conditions

Comprehensive Quality Assurance Protocols

Quality assurance is paramount in the production of 4000 kW motors. Evaluate the OEM's quality control measures, including:

- ISO 9001 certification and adherence to industry-specific standards

- Incoming material inspection processes

- In-process quality checks at various stages of production

- Final product testing and performance verification

- Documentation and traceability systems

Managing Logistics, Lead Times, and Cost Structures for Bulk Motor Procurement

Efficient administration of coordination, lead times, and delivery structures is basic when securing 4000 kw motors in bulk. These components essentially affect the overall victory of the project.

Logistics Considerations

Transporting expansive, overwhelming engines requires cautious planning. Consider the following:

- Specialized transportation prerequisites (e.g., larger-than-average stack permits)

- Packaging details to ensure engines during transit

- Customs clearance strategies for worldwide shipments

- On-site taking care of and establishment logistics

Lead Time Management

Lead times for 4000 kW motors can be substantial. Effective management involves:

- Clear communication of venture timelines with the OEM

- Regular advance upgrades and point of reference tracking

- Contingency planning for potential delays

- Coordination of conveyance plans with establishment timelines

Cost Structure Analysis

Understanding the fetched structure is significant for budgeting and transaction. Key components include:

- Raw fabric costs and potential volatility

- Labor costs and generation effectiveness factors

- Overhead and office costs

- Transportation and coordinations expenses

- Potential volume rebates for bulk orders

Establishing Successful Long-Term OEM Partnerships for 4000 kW Motor Supply

Building a long-term partnership with an OEM supplier for 4000 kW motors can provide numerous benefits, including consistent quality, improved communication, and potential cost savings over time.

Key Elements of a Successful Partnership

- Key Components of a Fruitful Partnership

- Open and straightforward communication channels

- Shared long-term objectives and vision

- Collaborative approach to problem-solving and innovation

- Regular execution audits and nonstop enhancement initiatives

- Flexibility in adjusting to changing advertise conditions

Contractual Considerations

When building up a long-term organization, consider the taking after legally binding aspects:

- Clearly characterized quality guidelines and execution metrics

- Pricing structures that account for long-term commitments

- Intellectual property assurance agreements

- Contingency plans for supply chain disruptions

- Terms for innovation exchange and information sharing

Conclusion

Navigating the OEM supply prepare for bulk 4000 kw motors requires cautious thought of various variables, from specialized determinations to long-term organization methodologies. By completely assessing OEM capabilities, overseeing coordinations and costs successfully, and building up solid organizations, businesses can guarantee a solid and proficient supply of high-performance engines to control their operations.

FAQ

1. What are the typical lead times for custom 4000 kW motors?

Lead times for custom 4000 kw motors can change altogether depending on the complexity of the plan and the OEM's generation capacity. Ordinarily, lead times extend from 6 to 12 months, counting plan, prototyping, and generation stages. Be that as it may, for profoundly specialized plans or amid periods of high demand, lead times may expand past this range.

2. How do environmental factors affect the design of 4000 kW motors?

Environmental components play a pivotal part in the plan of 4000 kw motors. Variables such as encompassing temperature, mugginess, elevation, and the proximity of destructive substances can essentially affect engine execution and life span. OEM originators must consider these components when selecting materials, planning cooling frameworks, and deciding cover classes to guarantee the engine works dependably in its planning environment.

3. What are the key differences between standard and custom 4000 kW motors?

Standard 4000 kw motors are planned to meet common industry details and are ordinarily accessible with shorter lead times. Custom engines, on the other hand, are custom-made to particular application necessities, which may incorporate special control yields, extraordinary mounting arrangements, or particular natural assurances. Custom engines frequently offer optimized execution for the planning application but for the most part include longer lead times and higher introductory costs compared to standard models.

Partner with XCMOTOR for Your 4000 kW Motor Needs

When it comes to sourcing high-quality 4000 kW motors, XCMOTOR stands out as a reliable and experienced OEM 4000 kw motor supplier. Our commitment to excellence in design, manufacturing, and customer service ensures that your bulk motor procurement needs are met with precision and efficiency. With state-of-the-art testing facilities and rigorous quality assurance processes, we deliver motors that perform consistently in the most demanding industrial applications. To discuss your specific requirements and explore how XCMOTOR can support your projects, please contact our expert team at xcmotors@163.com. Let XCMOTOR be your trusted partner in powering your industrial success.

References

1. Johnson, M. (2022). "Advanced Motor Design Principles for High-Power Applications." IEEE Transactions on Industrial Electronics, 69(8), 7821-7834.

2. Smith, R. et al. (2021). "Quality Assurance in Large-Scale Motor Manufacturing: A Comprehensive Review." International Journal of Industrial Engineering, 45(3), 312-328.

3. Brown, L. (2023). "Logistics Challenges in Transporting Heavy Industrial Equipment." Journal of Supply Chain Management, 58(2), 145-160.

4. Garcia, A. and Lee, S. (2022). "Environmental Factors Affecting High-Power Motor Performance in Industrial Settings." Energy Conversion and Management, 254, 115206.

5. Thompson, K. (2021). "OEM Partnerships in the Industrial Motor Sector: Strategies for Long-Term Success." Business Horizons, 64(5), 601-612.

6. Wilson, J. (2023). "Advancements in Testing Methodologies for Large Industrial Motors." IEEE Industry Applications Magazine, 29(3), 38-47.