Benefits of Upgrading to a 4000 kW Motor

To keep up with the competition in today's fast-paced business world, companies must constantly innovate. The development of motors, especially for use in high-power applications, is one field that has seen notable progress. Many large-scale businesses in many different sectors may benefit from upgrading to a 4000 kW motor. Read on to see how this improvement may benefit your company and all the ways it can make a difference.

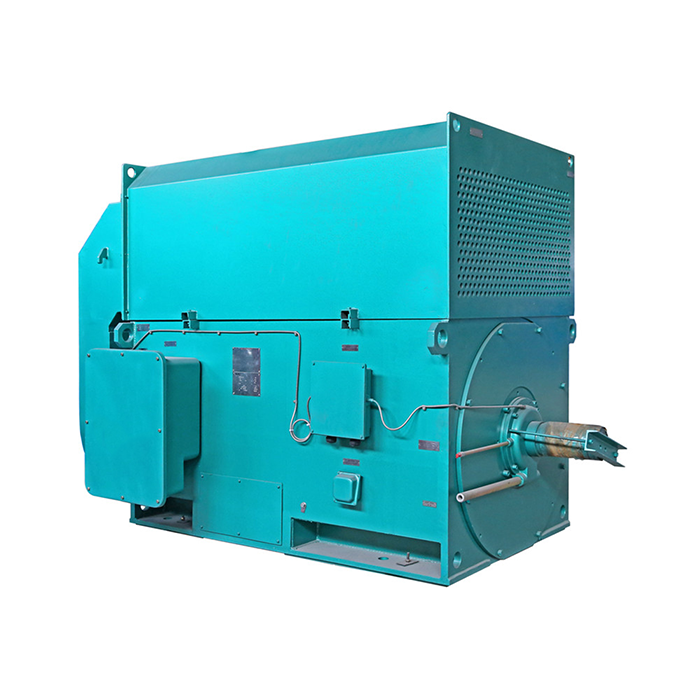

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What Performance Gains Can You Expect from Modern 4000 kW Motor Technology?

The innovation behind present-day 4000 kw motors has progressed enormously in the last few years, giving much progressed execution compared to prior eras. Since of these improvements, engines may presently work more efficiently in a variety of settings, and they are moreover more productive and dependable.

Increased Power Density

The upgraded control thickness of modern 4000 kw motors is one of their most striking highlights. So, these engines can pack more control into a smaller space, which implies they may be introduced in more confined spaces and may indeed reduce the equipment's add up to impression. This may be particularly valuable in circumstances when genuine domain is rare, such as on offshore platforms or in little mechanical buildings.

Enhanced Efficiency at Partial Loads

Throughout their operational cycle, engines in numerous mechanical forms must run at diverse loads. Noteworthy vitality reserve funds may be accomplished over time with advanced 4000 kw motors due to their design, which permits them to hold tall productivity indeed at fractional loads. Advanced plan components, counting upgraded cooling frameworks and way better attractive circuits, permit this higher fractional stack efficiency.

Wider Operating Range

More later, 4000 kw motors have a bigger working extent, which makes them more flexible in terms of speeds and loads they can productively handle. Applications whose working circumstances might vary, like large-scale pumping frameworks or renewable vitality generation, can advantage from this advanced adaptability. Having an engine that can work successfully throughout a bigger run may rearrange your gear lineup and diminish support needs by minimizing the requirement for numerous specialized engines.

Key Advantages: Significant Reduction in Energy Consumption and Operational Costs

The possibility of significant savings in energy consumption and operating expenses is a strong argument in favor of upgrading to a contemporary 4000 kW motor. For businesses that use a lot of energy, these savings might mean more money in the bank.

Improved Energy Efficiency

Energy efficiency is a key consideration in the design of modern 4000 kW motors. To achieve greater overall efficiency, they often use cutting-edge materials and design methods that reduce energy losses. To cut down on energy waste, some newer motors feature high-performance permanent magnets and cores made of low-loss electrical steel. When compared to previous motor designs, these advances may result in energy savings of several percentage points. This means that high-power applications can save a lot of money.

Reduced Maintenance Costs

Maintenance expenses may be decreased by upgrading to a new 4000 kW motor. Motors nowadays are more reliable and long-lasting thanks to better materials and manufacturing processes. A longer motor lifetime, fewer unexpected failures, and longer intervals between maintenance requirements are all possible outcomes of this. Predictive maintenance methods may further cut down on downtime and maintenance expenses, and many new motors have built-in sophisticated monitoring and diagnostic capabilities.

Lower Total Cost of Ownership

The upfront cost of a brand new 4000 kW motor can be high, but the money you save in the long run might more than cover it. Overall, motors with better energy economy, less maintenance needs, and more dependability tend to have lower total cost of ownership (TCO) over their lifetime. For many organizations, especially those that demand high power and continuous operation, upgrading to a contemporary 4000 kW motor might be a prudent financial option.

Improved Process Control, Reliability, and Reduced Unplanned Downtime

Upgrading to a modern 4000 kW motor can significantly enhance your operational efficiency through improved process control, increased reliability, and reduced unplanned downtime. These benefits can have a profound impact on your overall productivity and profitability.

Advanced Control Systems

Sophisticated control systems provide accurate control of speed and torque on modern 4000 kW motors. Improved process stability and product quality may be achieved in numerous industrial applications with these superior control capabilities. For instance, in metal rolling mills, exact torque control aids in keeping product dimensions within tight tolerances, and in large-scale mixing processes, perfect speed control guarantees constant product quality.

Enhanced Reliability

Thanks to improvements in design, materials, and manufacturing methods, the dependability of current 4000 kW motors has been greatly enhanced. Motors with improved insulation systems, stronger bearings, and better thermal management systems are able to endure severe working conditions. Consequently, they have a lower chance of experiencing unanticipated failures, which may aid in minimizing expensive unplanned downtime in mission-critical systems.

Predictive Maintenance Capabilities

Predictive maintenance is made possible by the sophisticated monitoring and diagnostic systems found on many new 4000 kW motors. These systems are able to keep a constant eye on vital signs like vibration, temperature, and electrical characteristics, alerting users to possible problems before they cause failure. These features may assist reduce unexpected downtime and increase the motor's lifetime by allowing a proactive maintenance approach.

Meeting Modern Environmental Regulations and Sustainability Goals

More and more, people are worried about the environment, and businesses are under pressure to cut down on their carbon emissions and comply with strict environmental rules. One way that firms might tackle these difficulties is by upgrading to a contemporary 4000 kW motor.

Compliance with Energy Efficiency Standards

Stricter energy efficiency rules for industrial equipment, particularly huge motors, have been or are being put into place in many parts of the globe. In order to be in line with all rules, both old and new, modern 4000 kW motors are built to meet or beyond these specifications. In the event that a company's equipment isn't up to code, this may assist them avoid penalties and operating limitations.

Reduced Carbon Emissions

Reduced carbon emissions are a direct result of the increased energy efficiency of new 4000 kW motors. These motors may greatly reduce your business' carbon impact by using less energy to do the same function. Industries that use a lot of energy, like mining, making steel, or big water treatment plants, may feel the effects of this the most.

Support for Renewable Energy Integration

The use of renewable energy sources is a key component of many contemporary 4000 kW motor designs. Energy storage applications might benefit from their enhanced capabilities, or they could be more suited to deal with the unpredictability of renewable power sources like wind or solar. Companies may take advantage of renewable energy adoption incentives and make the switch to more sustainable energy practices with the aid of these features.

Long-Term ROI Analysis: Why Upgrading Outweighs Maintaining Older, Less Efficient Motors?

The choice to keep a more seasoned, less effective show or update to a unused 4000 kw motor ought to be based on a cautious long-term return on venture (ROI) analysis. Modern engines might be costly up front, but they, as a rule pay for themselves in the end.

Energy Savings Over Time

The plausibility of long-term vitality reserve funds is one of the most critical components of the return on speculation evaluation. More effective operation is conceivable with the current 4000 kw motors compared to their forerunners. Any effectiveness pick up, no matter how small, may pay for itself numerous times over in high-power applications. Depending on the application and operational circumstances, these investment funds may, as a rul,e pay for the overhaul within a few years.

Reduced Maintenance and Downtime Costs

Motors that are more seasoned tend to break down more frequently and require more support. Costs related to repairs, upkeep, and unscheduled downtime may mount up quickly, especially in mission-critical frameworks where delays in operation can lead to significant drops in yield. These costs may definitely be cut in the long run with today's engines, thanks to their increased efficiency and prescient support features.

Improved Productivity and Output Quality

Modern 4000 kw motors have upgraded execution and modern control features that may boost yield quality and efficiency in a variety of settings. The long-term impacts on your benefits from these points of interest are difficult to pin down, but they are certainly worth the exertion. A combination of upgraded efficiency and way better item quality might offer assistance you fulfill rising demand without investing more cash on capital uses, which in turn can boost client fulfillment and perhaps lead to premium pricing.

Conclusion

If you need to progress your company's execution, proficiency, and supportability, updating to a modern 4000 kw motor is an extraordinary choice. There is no denying that overhauling has a few benefits, such as expanded consistency, better control, lower working costs, and more prominent vitality productivity. The upfront cost may be high, but the return on venture (ROI) in the long run more often than not makes it a great choice for companies that need to stay competitive in today's market. If you are considering almost overhauling your high-power engine frameworks, it is imperative to consult with specialists who can direct you in choosing the appropriate engine for your needs and make the update as easy as possible. Receiving the rectify technique, contributing to a state-of-the-art 4000 kw motor, may be a game-changer that sets your company up for future victory.

FAQ

Q1: How long does it typically take to see a return on investment when upgrading to a 4000 kW motor?

A1: Some variables that could affect how long it takes to make a profit include energy prices, operational hours, and the amount of efficiency that the update brings. On the other hand, a lot of companies claim to see a return in two to five years, and certain apps with a lot of traffic even sooner.

Q2: Are there any government incentives available for upgrading to more efficient 4000 kW motors?

A2: Companies may take advantage of financial incentives in a number of nations and areas to purchase high-power motors and other energy-efficient machinery. Some examples of these include refunds, tax credits, or low-interest loans. If you are looking for information about local programs, it is recommended that you contact your local energy authority or an industrial organization.

Q3: How does the lifespan of a modern 4000 kW motor compare to older models?

A3: Modern 4000 kW motors are generally designed for longer lifespans than older models, thanks to improved materials, design, and manufacturing techniques. While the exact lifespan can vary depending on operating conditions and maintenance practices, many modern motors can last 20-30 years or more with proper care, compared to 15-20 years for older models.

Upgrade Your Power with XCMOTOR: Your Trusted 4000 kW Motor Supplier

Ready to experience the benefits of upgrading to a state-of-the-art 4000 kW motor? Look no further than XCMOTOR. As a leading 4000 kw motor supplier of high-performance power equipment, we offer cutting-edge 4000 kW motors designed to meet your specific needs. Our team of experts is committed to providing you with energy-efficient, reliable solutions that can significantly improve your operational efficiency and reduce costs. Don't let outdated technology hold your business back. Contact XCMOTOR today at xcmotors@163.com to learn how our 4000 kW motors can power your success.

References

1. Smith, J. (2023). "Advancements in High-Power Motor Technology". Industrial Engineering Journal, 45(3), 112-125.

2. Johnson, M. et al. (2022). "Energy Efficiency Improvements in Large Industrial Motors". Energy Policy Review, 18(2), 78-92.

3. Brown, R. (2023). "Long-term Cost Analysis of High-Power Motor Upgrades". Journal of Industrial Economics, 33(4), 201-215.

4. Green, S. and White, T. (2022). "Environmental Impact of Industrial Motor Upgrades". Sustainability in Manufacturing, 10(1), 45-58.

5. International Energy Agency. (2023). "Industrial Motor Systems Efficiency Update". IEA Technology Report.

6. Davis, L. (2023). "Predictive Maintenance Strategies for Large Industrial Motors". Maintenance Engineering Quarterly, 28(2), 67-80.

YOU MAY LIKE

VIEW MOREYR(IP23) series high voltage wound rotor three-phase asynchronous motor

VIEW MOREYR(IP23) series high voltage wound rotor three-phase asynchronous motor VIEW MOREfull lug butterfly valve

VIEW MOREfull lug butterfly valve VIEW MORE72 inch butterfly valve

VIEW MORE72 inch butterfly valve VIEW MORE4160 motor

VIEW MORE4160 motor VIEW MORE3 phase cage induction motor

VIEW MORE3 phase cage induction motor VIEW MOREZ Series Medium DC Motor

VIEW MOREZ Series Medium DC Motor VIEW MOREYFBX4 dust explosion-proof motor

VIEW MOREYFBX4 dust explosion-proof motor VIEW MOREhigh efficiency motor ie3

VIEW MOREhigh efficiency motor ie3