OEM slip ring rotor motor customization involves tailoring these specialized motors to meet specific industrial requirements, encompassing everything from power ratings and environmental conditions to unique mechanical interfaces. Unlike standard off-the-shelf solutions, customized slip ring rotor motors offer enhanced starting torque capabilities, variable speed control, and adaptability to demanding operational environments. This comprehensive approach ensures optimal performance across diverse applications including heavy machinery, process equipment, and automation systems while delivering cost-effective solutions that align with your operational goals and technical specifications.

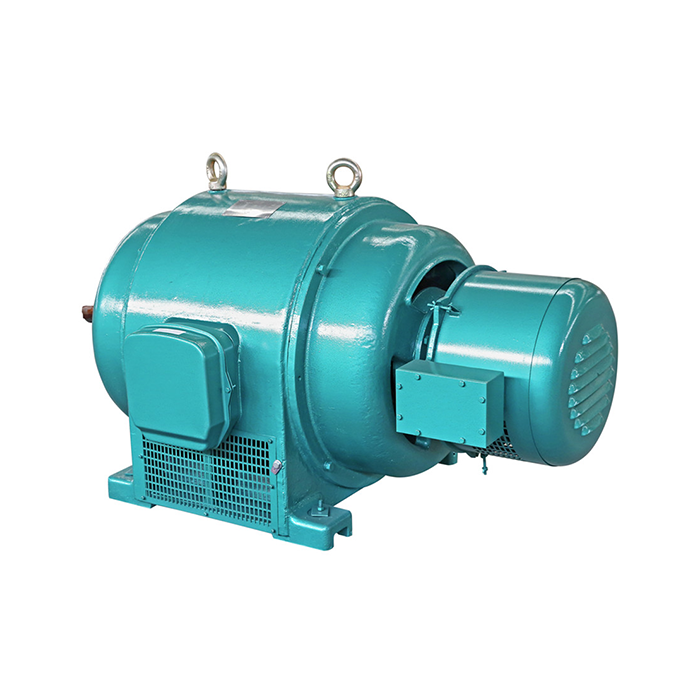

Series:YRQ

Voltage range:380V±5%

Power range:45-710kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Slip Ring Rotor Motors and Their Customization Needs

Slip ring rotor motors operate through a sophisticated mechanism that distinguishes them from conventional squirrel cage designs. The rotor features slip rings and carbon brushes that allow external resistance control, enabling superior starting characteristics and speed regulation capabilities. This design provides exceptional starting torque, typically reaching up to 280% of rated torque while maintaining relatively low starting current between 350-450% of rated current.

The principal contrast lies in the rotor development. Whereas squirrel cage engines have closed rotor bars, slip ring plans consolidate windings associated to outside slip rings. This arrangement permits administrators to present outside resistance during startup, decreasing the starting current draw and giving smooth increasing speed profiles. The capacity to alter rotor resistance makes these engines especially profitable in applications requiring controlled beginning arrangements or variable speed operation.

Customization becomes fundamental when standard engine determinations cannot meet particular operational requests. Businesses requiring exact speed control, tall beginning torque, or operation in challenging natural conditions advantage essentially from custom-fitted arrangements. Fabricating offices, preparing overwhelming materials, mining operations taking care of considerable loads, and control era gear request engines designed to their correct prerequisites or maybe than bland alternatives.

Key Factors to Consider When Customizing Slip Ring Rotor Motors

Successful engine customization starts with a comprehensive examination of operational prerequisites and natural conditions. Understanding your particular application requests guarantees the coming about engine conveys ideal execution through its service life.

Performance prerequisites shape the establishment of any customization extension. Stack characteristics, counting steady versus variable loads, obligation cycles, and torque profiles, directly impact engine plan parameters. Applications including visit begins and stops require distinctive determinations than persistent obligation operations. The YRQ(JR) arrangement engines, with their control run crossing 45-800kW and voltage compatibility at 380V±5%, illustrate how producers adjust standard stages to meet differing requirements.

Environmental considerations essentially affect customization choices. Working temperatures, mugginess levels, and exposure to destructive substances influence fabric determination and security levels. The IP23 security rating gives satisfactory security for most indoor applications, despite the fact that harsher situations may require improved fixing. Height, surrounding temperature varieties, and potential exposure to clean or dampness impact cover frameworks and cooling methods.

Here are the critical design parameters that require careful consideration during customization:

- Rotor Construction Materials: Selection impacts durability, thermal characteristics, and electrical performance. Advanced copper alloys and specialized insulation materials enhance reliability while maintaining optimal conductivity and heat dissipation properties.

- Slip Ring Configuration: Ring diameter, material composition, and surface treatments affect brush life and electrical contact quality. Proper sizing ensures consistent performance and reduces maintenance requirements throughout the motor's operational life.

- Winding Design: Custom winding configurations optimize torque characteristics, efficiency, and thermal management. Specialized wire types and insulation systems accommodate specific voltage requirements and environmental conditions.

- Bearing Selection: Premium bearings from established manufacturers like SKF, NSK, or FAG can be specified based on load conditions, speed requirements, and maintenance preferences, ensuring extended operational life and reduced downtime.

These customization options work together to create motors precisely matched to application requirements, eliminating the compromises often associated with standard products while ensuring reliable long-term performance.

Common Challenges and Solutions in OEM Slip Ring Rotor Motor Customization

Motor customization projects frequently encounter technical and logistical challenges that require proactive management and engineering expertise. Understanding these potential issues enables better planning and more successful project outcomes.

Ongoing Operational Maintenance

Brush wear and slip ring maintenance represent ongoing operational considerations for a slip ring rotor motor. The sliding contact between carbon brushes and slip rings creates natural wear patterns that require periodic attention. Advanced brush materials and optimized ring surface treatments significantly extend service intervals. Proper brush pressure adjustment and regular inspection schedules minimize unexpected failures while maintaining consistent electrical contact and motor reliability.

Performance and Efficiency Balancing

Efficiency optimization presents another common challenge, particularly when balancing performance requirements with energy consumption goals. Variable speed applications in a slip ring rotor motor may require compromise between starting torque and running efficiency. Modern rotor designs incorporate advanced materials and optimized geometries to achieve better overall performance characteristics without sacrificing reliability or increasing maintenance complexity for the end user.

Project Timeline and Cost Management

Manufacturing lead times and cost management create significant project pressures. Complex customizations for a slip ring rotor motor, requiring specialized materials, can extend standard delivery timelines, making early engagement essential. Simultaneously, balancing advanced performance needs with budget constraints requires evaluating which modifications offer the greatest benefit. Strategic standardization of certain components often provides an optimal compromise between performance, cost-effectiveness, and schedule adherence.

How to Choose the Right OEM Partner for Slip Ring Rotor Motor Customization?

Selecting a suitable fabricating accomplice decides venture victory and long-term fulfillment with customized engine arrangements. The perfect accomplice combines specialized ability with fabricating capabilities and comprehensive back services.

Technical competency shapes the establishment of any fruitful association. Assess potential accomplices based on their designing capabilities, plan experience, and track record with comparable customization ventures. Producers with broad involvement in wound rotor engine innovation get the subtleties of slip ring plan and can give important direction all through the determination process.

Manufacturing quality and handle control guarantee steady item conveyance and dependable execution. Progressed generation procedures, counting exactness winding strategies and vacuum weight impregnation forms, contribute to prevalent engine reliability and expanded benefit life. Comprehensive testing conventions confirm that each engine meets indicated execution criteria some time recently shipment.

Here are the essential criteria for evaluating potential OEM partners:

- Engineering Support: Comprehensive design assistance, application analysis, and technical consultation services help optimize motor specifications for specific requirements while identifying potential issues early in the project timeline.

- Quality Certifications: Industry standard compliance, including ISO certifications and adherence to electrical safety standards, demonstrates commitment to consistent quality and regulatory compliance across all manufacturing processes.

- Service Network: Global support capabilities, including installation assistance, commissioning services, and ongoing technical support, ensure continued motor performance throughout its operational life while minimizing downtime risks.

- Warranty Coverage: Comprehensive warranty programs, typically offering 12 months from commissioning or 18 months from shipment, provide confidence in product quality and manufacturer commitment to customer satisfaction.

These partnership elements combine to create relationships that extend beyond initial motor delivery, providing ongoing support and expertise that enhance operational efficiency and equipment reliability over time.

Conclusion

Customized slip ring rotor motors provide essential solutions for demanding industrial applications requiring precise control, high starting torque, and reliable performance. Understanding the key factors involved in customization, from technical specifications to partner selection, enables informed decisions that optimize operational efficiency and long-term value. The combination of advanced engineering, quality manufacturing processes, and comprehensive support services ensures the successful implementation of customized motor solutions across diverse industrial sectors.

Frequently Asked Questions

Q1: How do slip ring rotor motors differ from squirrel cage motors in terms of performance characteristics?

A: Slip ring rotor motors offer superior starting torque capabilities, typically achieving up to 280% of rated torque compared to standard squirrel cage designs. The external resistance control through slip rings enables smooth acceleration profiles and variable speed operation, making them ideal for applications requiring controlled starting sequences or load-sensitive operation. While squirrel cage motors are simpler and require less maintenance, slip ring designs provide greater operational flexibility and control precision.

Q2: What factors influence the lead time for customized motor manufacturing?

A: Standard customization ventures ordinarily require 4-6 weeks for completion, even though complex adjustments may amplify this timeline. Variables influencing lead time incorporate detail complexity, fabric accessibility, and production planning. One-of-a-kind bearing necessities, specialized separator frameworks, or adjusted mechanical interfacing may require extra fabrication time. Early engagement with nitty gritty details makes a difference optimize conveyance plans and guarantees reasonable extend timelines.

Q3: What maintenance considerations apply to customized slip ring rotor motors?

A: Normal upkeep centers fundamentally on brush and slip ring assessment, regularly each 6-12 months depending on working conditions. Appropriate oil of orientation, electrical association confirmation, and separator resistance testing offer assistance keep up ideal execution. The capacity to indicate premium orientation from producers like SKF, NSK, or FAG amid customization decreases long-term support prerequisites whereas amplifying benefit interims and progressing generally reliability.

XCMOTOR: Your Trusted Slip Ring Rotor Motor Manufacturer

When searching for a reliable slip ring rotor motor supplier, XCMOTOR stands out through decades of engineering expertise and commitment to customer satisfaction. Our comprehensive approach to motor customization ensures each solution precisely matches your operational requirements while delivering exceptional reliability and performance.

Ready to explore customized motor solutions for your specific application? Our experienced engineering team stands ready to analyze your requirements and develop tailored recommendations that optimize performance while meeting your budget and timeline constraints. Contact us at xcmotors@163.com to discuss your project specifications and receive detailed technical proposals. Visit motorxc.com to learn more about our complete range of motor solutions and engineering capabilities.

References

1. Chapman, Stephen J. "Electric Machinery Fundamentals, 5th Edition." McGraw-Hill Education, 2012.

2. Sen, P.C. "Principles of Electric Machines and Power Electronics, 3rd Edition." John Wiley & Sons, 2013.

3. IEEE Standards Association. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017.

4. Boldea, Ion and Syed A. Nasar. "The Induction Machines Design Handbook, 2nd Edition." CRC Press, 2010.

5. National Electrical Manufacturers Association. "Motors and Generators Standards Publication MG 1-2016." NEMA, 2016.

6. Pyrhonen, Juha, Tapani Jokinen, and Valeria Hrabovcova. "Design of Rotating Electrical Machines, 2nd Edition." John Wiley & Sons, 2014.