Selecting the right high-voltage AC motor for industrial applications demands careful consideration of technical specifications, operational requirements, and long-term performance expectations. When evaluating a 2500 kw motor, procurement teams must balance power output, efficiency ratings, and environmental factors to ensure optimal performance across diverse industrial sectors. Understanding motor specifications, voltage ranges, protection levels, and application-specific requirements enables engineers to make informed decisions that maximize operational reliability while minimizing total cost of ownership. This comprehensive guide addresses critical selection criteria, maintenance protocols, and emerging technologies that define modern high-voltage motor performance standards.

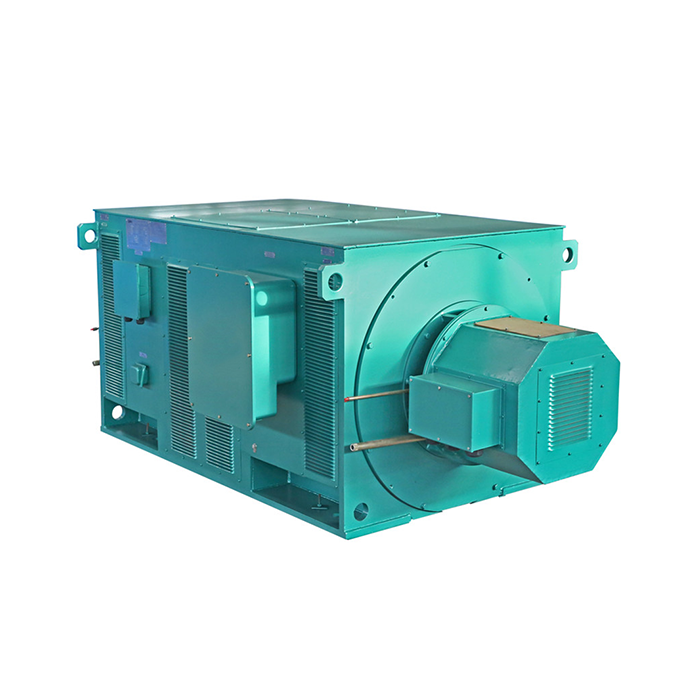

Series:YKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Comprehensive Specifications of 2500 kW High-Voltage AC Motors

High-voltage AC engines in the 2500 kW run speak to advanced designing arrangements outlined for requesting mechanical situations. These engines work inside voltage ranges crossing from 3000V to 11000V, with standard resiliences of ±5% guaranteeing steady execution over shifting control framework conditions. The adaptability in voltage choices permits integration into different electrical framework arrangements commonly found in fabricating, vitality era, and prepare industries.

Power output capabilities extend from 200 kW to 6300 kW, providing scalability for applications requiring different performance levels. The 2500 kw motor configuration typically operates at 50 Hz frequency with IP54 protection class, offering adequate protection against dust ingress and water splashing from any direction. This protection level proves essential for industrial environments where contamination and moisture present ongoing challenges to motor reliability.

Advanced cooling strategies, especially the IC611 arrangement, guarantee ideal warm administration amid nonstop operation. This cooling approach combines inner discuss circulation with outside warm trade, keeping up working temperatures inside secure parameters indeed amid crest stack conditions. The vigorous development highlights precision-cast outlines that give extraordinary mechanical quality whereas encouraging prevalent warm scattering all through amplified operational cycles.

Compliance with JB/T 12730 and JB/T 12729 benchmarks ensures adherence to thorough quality benchmarks built up for high-voltage engine fabricating. These benchmarks envelop electrical security, mechanical astuteness, and execution consistency necessities that guarantee dependable operation over differing mechanical applications.

How to Select the Best 2500 kW Motor for Your Industrial Needs?

Effective engine choice requires efficient assessment of operational parameters, natural conditions, and execution desires particular to each application. Stack profile investigation shapes the establishment of this determination handle, as continuous-duty applications request diverse engine characteristics compared to discontinuous or variable-load scenarios.

Environmental variables essentially impact engine choice choices. Surrounding temperature ranges, elevation contemplations, and barometrical conditions influence engine execution and life span. Engines ordained for open air establishments require upgraded security levels and specialized coatings to withstand climate introduction, whereas indoor applications may prioritize commotion diminishment and space efficiency.

Here are the core selection criteria that guide optimal motor specification:

- Power Requirements Analysis: Evaluate actual load demands versus rated capacity, considering peak torque requirements and duty cycle variations. Proper sizing prevents both underperformance and unnecessary energy consumption while ensuring adequate reserve capacity for operational flexibility.

- Voltage Compatibility Assessment: Match motor voltage ratings with existing electrical infrastructure capabilities, considering voltage regulation requirements and power distribution system characteristics. Proper voltage selection optimizes efficiency while minimizing electrical stress on motor components.

- Environmental Protection Needs: Assess installation environment for contamination levels, moisture exposure, and temperature variations. Select appropriate protection class ratings and specialized features to ensure reliable operation under specific environmental conditions.

- Maintenance Accessibility Requirements: Consider installation location, space constraints, and maintenance access requirements when selecting motor configurations. Easier maintenance access reduces service costs and minimizes downtime during routine inspections and repairs.

These choice criteria work together to recognize engine arrangements that convey ideal execution whereas assembly particular operational prerequisites. Adjusting these variables guarantees long-term unwavering quality and cost-effectiveness over differing mechanical applications.

Maintenance Best Practices for High-Voltage 2500 kW Motors

Bearing Maintenance Protocols

Bearing maintenance is crucial for preserving motor performance, especially for high-quality SKF, NSK, or FAG bearings in applications like a 2500 kw motor. Proper lubrication schedules, consistent vibration monitoring, and precise temperature tracking prevent premature failure. These proactive strategies ensure smooth operation and significantly extend the operational lifespan by identifying wear before it escalates into catastrophic damage.

Electrical System Monitoring

Regular electrical insulation monitoring provides an early warning for deteriorating components in a 2500 kW motor. Conducting insulation resistance tests under controlled conditions reveals negative trends, signaling when preventive intervention is necessary. This proactive approach focuses on identifying potential electrical faults early, preventing unexpected and disruptive failures that could halt critical industrial processes.

Vibration and Environmental Analysis

Vibration analysis detects imbalances, misalignment, and bearing degradation in a 2500 kw motor before secondary damage occurs. Complementing this, environmental monitoring tracks ambient temperature, humidity, and contamination. Together, these techniques enable targeted maintenance, addressing root causes to ensure consistent performance and extended lifespan under varying operational demands.

Innovations and Energy Saving Technologies in 2500 kW Motors

Contemporary engine innovation consolidates progressed features that improve efficiency while lessening operational costs. Variable recurrence drives (VFDs) empower exact speed control that matches engine yield to genuine load requirements, conveying significant vitality investment funds compared to conventional fixed-speed operations.

Enhanced separator materials give predominant thermal and electrical properties that expand engine life expectancy while keeping up execution beneath demanding conditions. These materials stand up to warm degradation, dampness assimilation, and chemical defilement that truly constrain engine reliability in harsh mechanical environments.

Advanced rotor plan procedures minimize misfortunes while optimizing torque characteristics over shifting speed ranges. Accurately fabricating forms guarantees energetic adjustment that diminishes vibration and noise levels, making calmer, smoother operation that benefits both hardware life span and work environment.

Smart checking advances coordinated sensor systems that give real-time execution information, empowering prescient support procedures that avoid unforeseen disappointments. These frameworks screen basic parameters counting temperature, vibration, and electrical characteristics, transmitting information to centralized observing stages for investigation and trending.

Energy recuperation frameworks capture squander warm created during engine operation, diverting this warm energy for profitable applications within mechanical operations. This approach makes strides in the general framework proficiency while lessening office vitality utilization and natural impact.

Procurement Insights for 2500 kW Motors

Successful engine acquirement requires understanding advertise flow, provider capabilities, and long-term bolster necessities that guarantee dependable gear accessibility and benefit all through operational lifecycles. Lead times for high-voltage engines regularly run from 12 to 20 weeks, depending on determination complexity and customization requirements.

Supplier evaluation encompasses manufacturing capabilities, quality certifications, and technical support infrastructure that supports both initial installation and ongoing maintenance requirements. Established manufacturers provide comprehensive documentation, training resources, and spare parts availability that facilitate efficient 2500 kw motor management throughout service life.

Cost examination amplifies past starting buy cost to include establishment costs, commissioning necessities, and continuous operational costs. Add up to taken a toll of proprietorship calculations consider vitality utilization, support costs, and anticipated benefit life to distinguish alternatives that give ideal long-term value.

Quality affirmation conventions incorporate production line testing, documentation survey, and assessment strategies that confirm engine compliance with indicated necessities some time recently shipment. Comprehensive testing includes execution confirmation, separator testing, and vibration investigation that affirms engine availability for mechanical service.

Warranty terms and benefits bolster assurances that characterize producer duties for hardware execution and specialized help. Understanding these commitments makes a difference. obtainment groups select providers that give satisfactory assurance against absconds whereas guaranteeing get to to master specialized support when needed.

Conclusion

Selecting an suitable high-voltage AC engine requires cautious assessment of specialized details, operational necessities, and long-term execution desires. Understanding voltage ranges, assurance levels, effectiveness characteristics, and upkeep necessities empowers educated acquirement choices that optimize mechanical gear ventures. Present day engine innovations offer upgraded effectiveness, unwavering quality, and checking capabilities that provide quantifiable operational benefits over assorted mechanical sectors.

Frequently Asked Questions

Q1: What factors affect the efficiency of a 2500 kW high-voltage motor?

A: Engine productivity depends on a few key variables, including stack calculation, working temperature, voltage control, and mechanical misfortunes. Ideal productivity regularly happens at 75-85% the evaluated stack, whereas voltage variations past ±5% can diminish proficiency altogether. Appropriate upkeep of orientation, arrangement, and cooling frameworks keeps up peak effectiveness through the motor's operational life.

Q2: How often should preventive maintenance be performed on a 2500 kW motor?

A: Preventive support plans shift based on working conditions, but common suggestions incorporate month to month visual assessments, quarterly vibration investigation, semi-annual bearing grease, and yearly comprehensive electrical testing. Engines in cruel situations may require more visit support, whereas clean, controlled situations may expand interims slightly.

Q3: What are the advantages of choosing a 2500 kW AC motor over alternatives for industrial applications?

A: High-voltage AC engines offer predominant effectiveness, lower support prerequisites, and superior speed control capabilities compared to DC choices. They give amazing beginning torque, work dependably in harsh situations, and coordinated effectively with cutting edge control frameworks. Also, AC engines ordinarily offer longer benefit life and lower total proprietorship costs for continuous-duty mechanical applications.

XCMOTOR: Your Trusted Partner for High-Performance Industrial Motors

When sourcing a reliable 2500 kw motor supplier, XCMOTOR stands ready to support your industrial power equipment requirements with comprehensive solutions tailored to demanding operational environments. Our commitment to delivering high-efficiency, low-consumption motors ensures optimal performance across diverse industrial applications while providing exceptional value through superior engineering and manufacturing quality.

Ready to explore high-quality motor solutions for your industrial applications? Contact us at xcmotors@163.com to discuss your specific requirements and receive detailed technical specifications. Visit motorxc.com to learn more about our comprehensive product offerings and discover how XCMOTOR can support your power equipment objectives with reliable, efficient solutions.

References

1. Institute of Electrical and Electronics Engineers. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Standards Association, 2018.

2. National Electrical Manufacturers Association. "Energy Efficient Motors: Selection and Application Guide." NEMA Publication MG-1, 2020.

3. International Electrotechnical Commission. "Rotating Electrical Machines - Part 1: Rating and Performance." IEC 60034-1 Standard, 2017.

4. American Society of Mechanical Engineers. "Industrial Motor Efficiency and Reliability Guidelines." ASME Technical Paper Series, 2019.

5. Electric Power Research Institute. "Motor Maintenance and Reliability Best Practices for Industrial Applications." EPRI Technical Report, 2021.

6. International Organization for Standardization. "Condition Monitoring and Diagnostics of Machines - Vibration Analysis." ISO 20816 Standard Series, 2016.