When selecting the best 3.3 kv motor for high altitude applications, understanding the unique challenges these environments present becomes crucial. High altitude operations create reduced air density, affecting cooling performance and potentially impacting motor insulation systems. The optimal medium voltage motor for such conditions requires enhanced cooling capabilities, robust insulation class ratings, and specialized motor design considerations. These industrial motors must handle altitude-related derating factors while maintaining reliable performance across demanding applications, including mining operations, water pumping stations, and manufacturing facilities located at elevation.

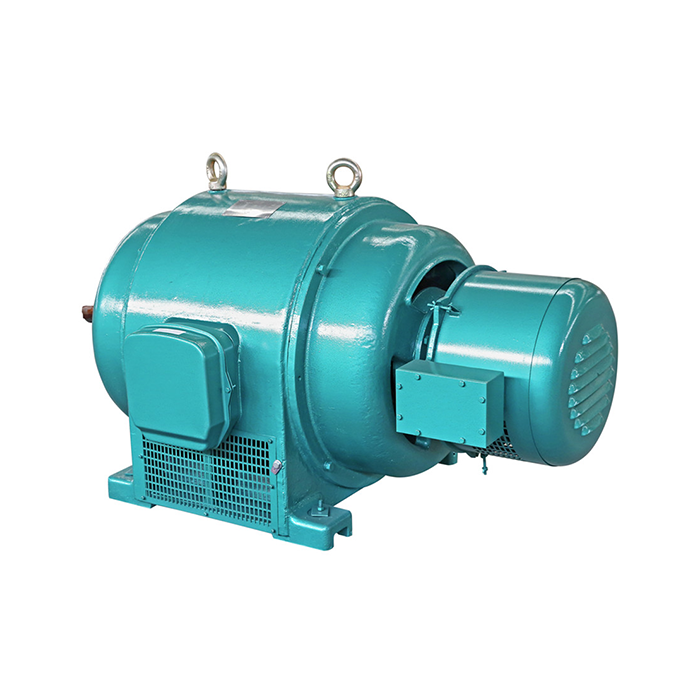

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High Altitude Motor Applications

High height situations show one-of-a-kind challenges for electric engine operations that standard gear cannot handle successfully. Fabricating offices, mining operations, and preparing plants found over 3,300 feet confront noteworthy operational obstacles that require specialized engine solutions.

The diminished discuss thickness at hoisted areas specifically impacts engine cooling effectiveness. Discuss gets to be more slender as height increases, diminishing its capacity to scatter warm generated during engine operation. This cooling challenge influences engine productivity evaluations and can lead to untimely gear disappointment without appropriate compensation.

Medium voltage engines working in these conditions involve extra push on the engine winding frameworks. The lower air weight influences separator execution, possibly lessening the dielectric quality of standard separator materials. Understanding these components makes a difference when engineers select fitting engine security frameworks and guarantees solid long-term operation.

Essential Selection Criteria for High Altitude Motors

Choosing the right mechanical engine for tall elevation applications requires cautious assessment of different specialized variables. Engine testing measures ended up especially imperative when managing with diminished air density and temperature variations common at elevation.

Insulation lesson appraisals merit extraordinary consideration in tall elevation situations. Lesson F for Course H covers frameworks that give upgraded warm security, pleasing the extra warm buildup caused by diminished cooling productivity. The engine plan must account for derating variables, regularly requiring curiously large units to compensate for altitude-related execution reductions.

Motor effectiveness calculations require alteration for tall height conditions. Standard proficiency appraisals apply to ocean-level operations, but real execution diminishes with rise. Engineers must consider this derating when measuring variable recurrence drives and engine starter frameworks to guarantee satisfactory execution margins.

Cooling system design becomes critical for sustained operation. Enhanced 3.3 kv motor cooling methods, including improved ventilation systems and specialized heat dissipation techniques, help maintain optimal operating temperatures despite reduced air density.

Top High Altitude Motor Solutions

Heavy-Duty Industrial Motors for Extreme Conditions

Robust mechanical engines planned particularly for challenging situations offer extraordinary execution in tall height applications. These units highlight fortified engine winding arrangements that withstand the interesting stresses of diminished air pressure while keeping up reliable torque output.

The upgraded cover frameworks in these engines utilize progressed materials that stand up to corrosion under altitude-related push variables. Temperature stipend highlights naturally alter execution parameters to keep up ideal effectiveness over changing natural conditions.

Advanced engine security frameworks screen basic working parameters persistently. These frameworks identify potential issues some time recently they gotten to be genuine issues, amplifying gear life and diminishing upkeep costs. The defensive highlights incorporate vibration checking, temperature detecting, and cover resistance tracking.

Installation adaptability permits these engines to adjust to different mounting setups common in tall elevation offices. The measured plan approach empowers simple integration with existing frameworks whereas giving choices for future development or modification.

High-Performance Synchronous Motors

Synchronous motor technology provides excellent speed regulation and power factor control in high altitude applications. These motors maintain constant speed regardless of load variations, making them ideal for precision applications requiring consistent performance.

The permanent magnet design eliminates slip losses common in induction motors, improving overall system efficiency. This efficiency advantage becomes particularly valuable in high altitude environments where cooling challenges already impact performance.

Advanced motor control systems optimize performance automatically, adjusting operating parameters to compensate for altitude-related factors. The intelligent control features include automatic voltage regulation, temperature compensation, and load balancing capabilities.

Maintenance requirements remain minimal due to the brushless design and robust construction. The sealed bearing systems resist contamination while providing long service life even in demanding environmental conditions.

Variable Speed Induction Motors

Induction motor technology combined with sophisticated variable frequency drives creates versatile solutions for high altitude applications. These systems provide precise speed control while maintaining high efficiency across a wide operating range.

The squirrel cage rotor design ensures reliable operation with minimal maintenance requirements. No brushes or slip rings eliminate potential failure points while providing consistent performance over extended periods.

Motor torque characteristics remain stable across varying altitude conditions when properly sized and configured. The robust construction handles the mechanical stresses associated with high altitude operations while maintaining smooth, vibration-free operation.

Energy management features optimize power consumption automatically, reducing operating costs while extending equipment life. These intelligent systems monitor load conditions continuously and adjust motor performance accordingly.

Global Market Considerations and Standards

International markets present varying requirements for high altitude 3.3 kv motor applications. Different regions maintain specific standards for motor testing, certification, and performance verification that manufacturers must address.

European markets emphasize energy efficiency standards and environmental compliance. Motor manufacturers must demonstrate adherence to strict efficiency guidelines while providing comprehensive documentation of environmental impact assessments.

North American standards focus heavily on safety certifications and operational reliability. The rigorous testing requirements ensure motors perform safely under all specified operating conditions, including extreme altitude environments.

Asian markets often prioritize cost-effective solutions without compromising performance quality. The balance between initial investment and long-term operational costs drives many purchasing decisions in these regions.

Emerging markets frequently require motors capable of handling infrastructure limitations and varying power quality conditions. Robust motor design becomes essential for reliable operation under these challenging circumstances.

Purchasing Recommendations and Technical Considerations

Successful motor selection requires thorough analysis of application requirements and environmental factors. Engineers must consider not only current needs but also potential future expansion or modification requirements.

Motor maintenance planning deserves careful attention during the selection process. High altitude locations often present logistical challenges for service and repair activities. Choosing motors with proven reliability records and readily available spare parts reduces operational risks.

Installation requirements vary significantly depending on altitude and environmental conditions. Proper planning for mounting, ventilation, and electrical connections ensures optimal performance and longevity.

Budget considerations should include both initial purchase costs and long-term operational expenses. While high-quality 3.3 kv motors may require larger initial investments, their superior reliability and efficiency often provide better total cost of ownership.

Technical support availability becomes crucial for successful long-term operation. Manufacturers offering comprehensive support services, including remote monitoring and troubleshooting capabilities, provide significant value for high-altitude installations.

Industry Trends and Summary

The tall height engine showcases progress advancing with progress in engine design, control innovation, and materials science. Savvy observing frameworks and prescient support capabilities are becoming standard highlights, making a difference administrators to maximize hardware reliability and execution. Vitality productivity enhancements and natural compliance prerequisites drive continued development in engine innovation. As mechanical operations extend into more challenging situations, specialized engine arrangements have become progressively imperative for maintaining competitive focal points and operational success.

Frequently Asked Questions

Q1: How does altitude affect motor performance and what derating factors should I consider?

A: Elevation influences engine cooling due to decreased disc thickness, regularly requiring 1% derating for every 330 feet over 3,300 feet rise. Engine productivity diminishes, and working temperatures increase, requiring cautious thought of cooling strategies and potential oversizing to keep up required execution levels.

Q2: What insulation class should I specify for high altitude motor applications?

A: Class F (155°C) or Class H (180°C) insulation systems work best for high altitude applications. These higher temperature ratings provide necessary thermal margin to compensate for reduced cooling efficiency at elevation, ensuring reliable long-term operation under challenging conditions.

Q3: Can standard variable frequency drives work with motors at high altitude?

A: Standard VFDs may require derating or upgraded cooling for tall elevation utilization. Numerous producers offer altitude-compensated drives or suggest particular establishment adjustments to guarantee legitimate operation. Counsel with drive producers for particular height impediments and suggested configurations.

Partner with XCMOTOR for High Altitude Motor Solutions

XCMOTOR provides tailored high-altitude motor solutions, optimizing 3.3 kV performance through precise cooling, insulation, and derating analysis, backed by comprehensive engineering, installation, and maintenance support. When you need a reliable 3.3 kv motor supplier for high altitude applications, XCMOTOR delivers proven solutions backed by industry expertise. We offer fast delivery, dedicated support including weekend availability, and 30-day return policies for your peace of mind.

Ready to discuss your high altitude motor requirements? Our expert team is prepared to help you select the perfect solution for your application. Contact us at xcmotors@163.com to connect with experienced professionals who understand your challenges and can provide the technical guidance you need.

References

1. IEEE Standards Association. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017.

2. National Electrical Manufacturers Association. "Motors and Generators - Application Guide for AC Adjustable Speed Drive Systems." NEMA MG 1-2016.

3. International Electrotechnical Commission. "Rotating Electrical Machines - Part 1: Rating and Performance." IEC 60034-1:2017.

4. Electric Power Research Institute. "Motor Efficiency and Reliability in Industrial Applications at High Altitude." Technical Report 3002011819, 2018.

5. Institute of Electrical and Electronics Engineers. "Recommended Practice for Motor Applications in Extreme Environmental Conditions." IEEE Std 841-2009.

6. American National Standards Institute. "Test Methods for Determining Motor Performance at Altitude." ANSI/IEEE C50.12-2005.