When industrial applications demand reliable, high-performance power solutions, a 20 hp dc electric motor emerges as an exceptional choice for businesses across manufacturing, automation, and energy sectors. These robust motors deliver superior torque control, excellent variable speed capabilities, and remarkable energy efficiency that translates into reduced operational costs. Unlike alternating current alternatives, DC motors provide precise speed regulation and instant response characteristics that make them indispensable for critical industrial machinery. The direct current design ensures consistent performance across diverse load conditions while offering simplified motor controller integration. Industries ranging from automotive manufacturing to renewable energy installations rely on these motors for their proven reliability and adaptability to demanding operational environments.

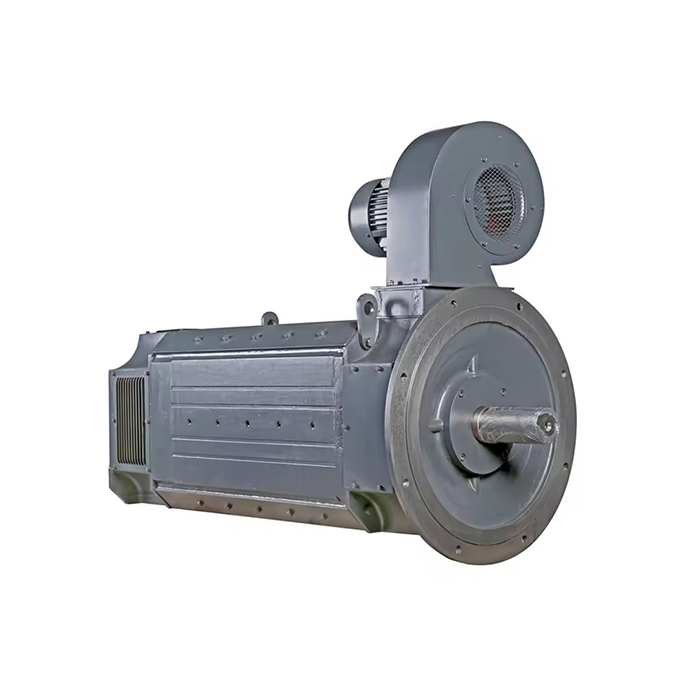

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Key Parameters and Performance Indicators

The technical specifications of a twenty horsepower DC motor reveal why these units excel in industrial environments.

1. Voltage and Power Supply Flexibility

These motors operate on a voltage range typically between 240V and 480V DC, providing versatility to adapt to different power supply configurations. This flexibility allows them to be used in diverse industries, where electrical systems can vary, ensuring that the motor can work effectively without major modifications to existing infrastructure.

2. Armature Current and Full Load Conditions

Under full load conditions, the armature current typically draws between 40-60 amperes. This range depends on factors such as the motor’s winding design and the specific demands of the application. Such current levels ensure that the motor provides sufficient power for heavy-duty industrial tasks, without risking damage to the electrical components or requiring excessive power from the supply source.

3. Torque Characteristics and Startup Performance

One of the most impressive features of these motors is their ability to generate maximum torque at startup. This provides the motor with exceptional load capacity when machinery requires immediate power, making it ideal for applications such as metal cutting, conveyors, and pumps where instant power is necessary to handle high initial loads. This high torque output also improves the motor's performance in systems with fluctuating or heavy-duty demands.

4. Speed Control and Versatility

The motor typically operates at base speeds between 1200-1800 RPM, but with the inclusion of variable speed controllers, it allows for precise regulation of speeds, ranging from near-zero to the motor's maximum rated speed. This adaptability makes the motor highly versatile, capable of meeting the needs of various machines requiring different speeds for optimal operation.

5. Efficiency and Thermal Management

Thermal management is crucial at this power level, and quality 20 HP DC motors are designed with advanced cooling systems and temperature monitoring to prevent overheating during continuous operation. With motor efficiency ranging from 85% to 92%, these motors significantly reduce energy consumption compared to older technologies. The increased efficiency not only results in lower operational costs but also extends the lifespan of the motor, providing long-term cost savings.

Core Benefits That Drive Industrial Success

Speed control precision stands out as the primary advantage driving adoption across automation applications. 20 hp dc electric motors respond instantaneously to controller inputs, enabling smooth acceleration and deceleration cycles that protect both the motor and connected equipment. This responsiveness proves invaluable in robotics and automation where precise positioning matters.

The regenerative braking capability offers another significant benefit. When the motor decelerates, it generates electricity that can be returned to the power supply system, further enhancing overall energy efficiency. This feature becomes particularly valuable in applications involving frequent start-stop cycles or variable load conditions.

Maintenance requirements remain minimal compared to complex AC drive systems. The brushless motor variants eliminate the need for regular brush replacement, reducing downtime and maintenance costs. Even traditional brushed designs offer predictable maintenance schedules that facilitate planning and budget allocation.

Load handling versatility enables these motors to excel across diverse applications. Whether driving pumps in water treatment facilities, powering conveyor systems in manufacturing plants, or operating compressors in HVAC installations, the consistent torque delivery ensures reliable performance regardless of varying load demands.

XCMOTOR's Superior DC Motor Solutions

Our engineering team at XCMOTOR has developed DC motor solutions that surpass conventional offerings through innovative design and quality manufacturing. While standard motors may struggle with heat dissipation and efficiency optimization, our units incorporate advanced permanent magnet technology and optimized motor winding configurations that deliver superior performance.

The inverter integration capabilities of our motors simplify installation and reduce system complexity. Standard motors often require extensive modification for proper controller compatibility, but our designs accommodate various motor controller types without additional hardware requirements. This compatibility reduces both initial installation costs and long-term maintenance complexity.

Durability testing reveals significant advantages in operational longevity. Our 20 hp dc electric motors undergo rigorous quality assurance protocols that exceed industry standards, ensuring reliable operation in challenging industrial environments. The robust construction withstands vibration, temperature fluctuations, and electrical stress that typically compromise lesser motor designs.

Our commitment to customer support extends beyond product delivery. We provide comprehensive technical assistance for gearbox selection, motor controller programming, and system optimization to maximize the benefits of your investment.

Maximizing Benefits Through Proper Implementation

Selecting the appropriate motor controller represents the crucial step in optimizing performance. Variable frequency drives designed specifically for DC applications unlock the full potential of speed control and energy management. Proper controller sizing ensures the motor operates within optimal parameters while providing necessary protection features.

Installation considerations significantly impact long-term performance. Adequate ventilation prevents thermal stress, while proper motor shaft alignment reduces mechanical wear. Electrical connections must accommodate the full-load current capacity with appropriate safety margins to prevent voltage drops that compromise performance.

Regular monitoring of motor parameters enables proactive maintenance scheduling. Tracking armature current, operating temperature, and vibration levels helps identify potential issues before they result in costly downtime. Modern monitoring systems can integrate with facility management software for automated alerts and performance tracking.

Application-specific optimization often involves gearbox selection to match motor characteristics with load requirements. Proper gear ratios enable the motor to operate in its most efficient speed range while delivering required torque to the driven equipment.

Critical Implementation Considerations

Power supply stability directly affects motor performance and longevity. DC power systems require proper filtering and regulation to prevent voltage fluctuations that can damage motor components. Installing appropriate surge protection devices protects against electrical transients that commonly occur in industrial environments.

Environmental factors demand careful consideration during motor selection and installation. Humidity, dust, and chemical exposure can compromise motor performance if not properly addressed through enclosure selection and environmental controls. The motor housing should match the environmental protection requirements of the specific installation location.

Safety protocols become paramount when working with high-power electrical equipment. Proper lockout/tagout procedures, personal protective equipment, and electrical safety training ensure safe operation and maintenance. Emergency shutdown systems should integrate with facility safety networks for comprehensive protection.

Load matching requires thorough analysis of application requirements. Oversizing motors wastes energy and increases costs, while undersizing leads to premature failure and poor performance. Professional load analysis ensures optimal motor selection for specific applications.

Conclusion

The benefits of implementing a 20 HP DC electric motor extend far beyond simple power delivery. These versatile machines provide exceptional speed control, superior torque characteristics, and remarkable efficiency that translates into tangible operational advantages. Whether your application involves manufacturing automation, HVAC systems, or renewable energy installations, the right DC motor solution delivers the performance and reliability your operations demand. The key lies in selecting quality equipment from experienced suppliers who understand the technical requirements and provide comprehensive support throughout the equipment lifecycle.

Frequently Asked Questions

Q1: How does a 20 HP DC motor compare to AC motors in terms of speed control?

A: DC motors provide superior speed control precision compared to standard AC motors. The direct current design enables smooth speed regulation from zero to maximum RPM without the complex variable frequency drives required for AC motor speed control. This results in better response time and more accurate positioning for automation applications.

Q2: What maintenance schedule should I follow for optimal performance?

A: Brushless DC motors require minimal maintenance, typically involving bearing lubrication every 6-12 months and annual electrical connection inspections. Brushed variants need brush inspection every 3-6 months depending on operating conditions. Regular monitoring of operating temperature and vibration levels helps prevent unexpected failures.

Q3: Can these motors operate efficiently at partial loads?

A: Yes, quality DC motors maintain good efficiency across a wide load range, typically 50-100% of rated capacity. The torque characteristics of DC motors make them well-suited for variable load applications, and proper motor controller selection can optimize efficiency even during light-load operation.

Partner with XCMOTOR for Your Industrial Motor Needs

Choosing the right 20 hp dc electric motor supplier can make the difference between operational success and costly equipment failures. XCMOTOR brings decades of experience in power equipment solutions, combining technical expertise with exceptional customer service to ensure your project succeeds.

Our original products come exclusively from trusted brands, guaranteeing the quality and reliability your operations demand. Fast delivery ensures your projects stay on schedule, while our 30-day return policy provides confidence in your investment. Unlike competitors who limit support to business hours, our dedicated team provides assistance both Saturday and Sunday.

We understand that selecting the right motor involves more than just horsepower ratings. Our technical team works closely with customers to analyze application requirements, recommend optimal motor controller configurations, and provide ongoing support throughout the equipment lifecycle. This comprehensive approach ensures you receive maximum value from your motor investment.

Ready to experience the superior performance and reliability of professional-grade 20 hp dc electric motors? Our team stands ready to discuss your specific requirements and recommend the ideal solution for your application. Contact us at xcmotors@163.com to schedule a consultation and discover why leading manufacturers trust XCMOTOR for their critical power equipment needs.

References

- Industrial Electric Motor Handbook: Performance Characteristics and Applications, 4th Edition, McGraw-Hill Professional, 2023

- Chapman, Stephen J. "Electric Machinery Fundamentals: DC Motor Analysis and Control Systems," McGraw-Hill Education, 2022

- National Electrical Manufacturers Association (NEMA). "Standards Publication for DC Motors and Generators," NEMA MG 1-2021

- IEEE Industry Applications Society. "Recommended Practice for Industrial and Commercial Power Systems Analysis," IEEE Std 399-2022

- Johnson, Robert M. "Motor Selection and Application Guide for Industrial Automation," Industrial Press Inc., 2023

- American Society of Mechanical Engineers. "Power Transmission and Motion Control: DC Motor Applications in Manufacturing," ASME Press, 2022