Optimizing a 4000 kW motor requires a detailed understanding that these high-capacity industrial machines demand precise management of thermal conditions, electrical efficiency, and mechanical stress factors. Enhancing performance involves implementing strategic maintenance protocols, integrating advanced cooling systems, and employing smart operational monitoring tools to ensure consistent, reliable performance. These measures are critical for maximizing uptime, minimizing energy losses, and preventing mechanical failures. In demanding applications such as manufacturing plants, power generation facilities, and heavy industrial sectors, careful attention to load balancing, vibration control, and system integration ensures the motor operates at peak efficiency while extending service life and reducing long-term operational costs.

4000 kW Motor Performance Optimization Tips

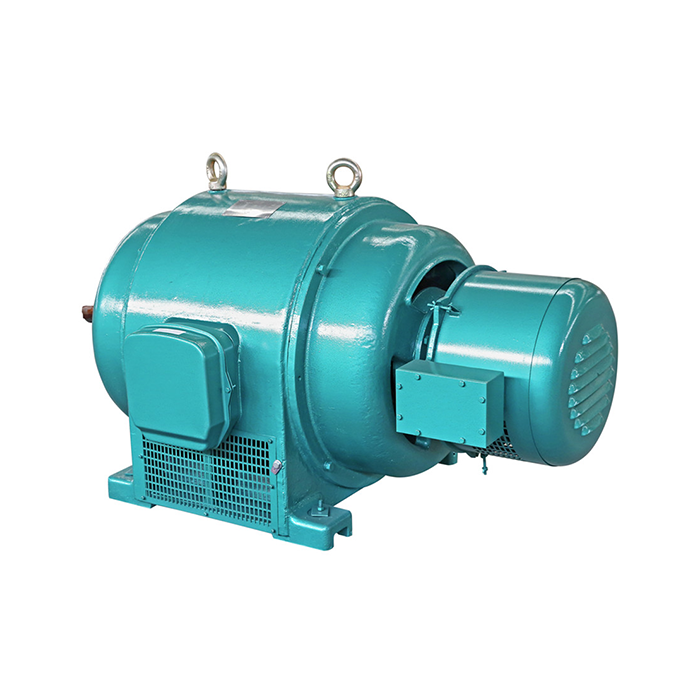

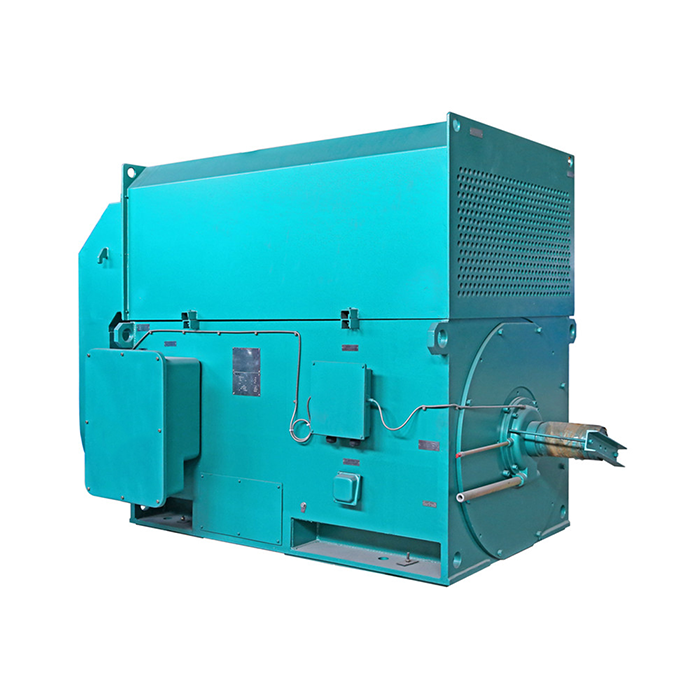

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Current Performance and Key Bottlenecks of 4000 kW Motors

High-capacity mechanical engines confront interesting operational challenges that straightforwardly affect efficiency and vitality utilization. Understanding these execution markers makes a difference designing groups distinguish optimization opportunities and anticipate exorbitant downtime.

Essential Performance Metrics for Large-Scale Motors

Power yield consistency remains the essential marker of engine wellbeing, with varieties surpassing 2% signaling potential issues. Proficiency appraisals regularly run between 94-96% for cutting-edge high-power engines, whereas warm behavior designs uncover operational push levels. Our engine details incorporate IP54 assurance levels, guaranteeing dependable operation in challenging mechanical environments.

Noise levels surpassing 85 dB(A) show a mechanical awkward nature or bearing weakening. The progressed plan of our frameworks keeps up commotion levels underneath this edge through precision-balanced rotors and high-quality bearing gatherings highlighting SKF, NSK, or FAG components based on client requirements.

Common Performance Bottlenecks in Industrial Applications

Mechanical wear speaks to the most predominant challenge, especially in bearing assemblies and rotor components. Warm over-burden conditions regularly create when cooling frameworks fall flat to keep up ideal working temperatures, driving to separator corrosion and decreased efficiency.

Electrical misfortunes amass through destitute associations, voltage lopsided characteristics, and insufficient control of rectification. These issues have been amplified in high-power applications where indeed little wasteful aspects contribute to critical vitality squander. Upkeep delays compound these issues, making cascading disappointments that require broad repairs.

Principles and Techniques for Optimizing 4000 kW Motor Performance

Effective optimization procedures combine progressed materials, cutting-edge cooling innovations, and prescient support conventions. These approaches guarantee reliable execution whereas minimizing operational costs.

Advanced Cooling System Designs and Material Selection

Premium cooling solutions significantly impact motor longevity and efficiency. Air cooling systems work well for moderate loads, while water and oil cooling provide superior temperature control for demanding applications. Our 4000 kw motors feature advanced cooling systems that effectively maintain optimal operating temperatures, preventing overheating and ensuring consistent performance.

The selection of superior materials extends operational life while reducing maintenance requirements. Vacuum pressure impregnation (VPI) creates superior insulation properties, protecting against moisture and contamination. Our manufacturing process includes precision die-casting of components and advanced winding techniques that enhance durability.

Predictive Maintenance and Monitoring Strategies

Sensor-based observing frameworks track basic parameters counting temperature, vibration, and electrical characteristics. PT100 temperature sensors in stator windings and orientation give real-time warm checking, empowering proactive intercession some time recently issues develop.

Regular grease plans avoid disappointments, whereas scheduled assessments detect wear designs early. These support conventions, combined with comprehensive testing during fabrication, guarantee dependable operation throughout the motor's benefit life. Our items experience energetic adjusting of rotor congregations and comprehensive quality control testing.

Comparing 4000 kW Motors with Alternative Solutions for Best Performance

Selecting the optimal motor capacity requires careful evaluation of power requirements, efficiency characteristics, and operational flexibility. Understanding these trade-offs guides informed procurement decisions.

Power Output Considerations and Application Suitability

The 4000 kW capacity gives amazing adjustment between control conveyance and framework complexity. Bigger 5000 kW choices offer higher yield but require more vigorous electrical foundation and expanded support assets. Our control extend amplifies from 200-3150 kW, pleasing assorted mechanical requirements.

Application reasonableness shifts essentially over businesses. Fabricating operations advantage from the steady control conveyance, whereas prepare control applications require exact speed control. Our engines exceed expectations in fans, water pumps, compressors, crushers, cutting machine apparatuses, and transportation apparatus applications.

Motor Configuration Options and Efficiency Impact

Synchronous motors provide superior power factor characteristics but require more complex control systems. Asynchronous designs offer simplicity and reliability, making them ideal for continuous operation applications. Our voltage range spans 3000V±5% through 11000V±5%, ensuring compatibility with various electrical systems.

Inverter-driven configurations enable precise speed control and energy optimization compared to direct online starting methods. The starting current of 5-7 times rated current and starting torque of 60-80% rated torque provide reliable startup characteristics across diverse applications.

Practical Guidelines for Selecting and Procuring High-Performance 4000 kW Motors

Strategic procurement decisions balance initial investment with long-term operational benefits. Understanding total cost of ownership principles guides effective purchasing strategies.

Critical Evaluation Criteria for Motor Selection

Efficiency ratings directly impact operational costs over the 4000 kw motor's lifespan. Modern high-efficiency motors reduce energy consumption while providing consistent performance. Our designs emphasize high efficiency and energy saving, low noise operation, minimal vibration, extended service life, and simplified installation procedures.

Brand reputation and after-sales support significantly influence long-term satisfaction. Comprehensive warranty coverage and technical support availability ensure operational continuity. Our products comply with JB/T 12730 and JB/T 12729 standards, guaranteeing quality and reliability.

Total Cost of Ownership Analysis and Strategic Sourcing

Initial purchase price represents only a fraction of lifetime costs. Energy consumption, maintenance requirements, and downtime expenses dominate total ownership costs. Our energy-efficient designs minimize operational expenses while maximizing productivity.

Customization capabilities enable optimal performance for specific applications. Lead time management and bulk purchase advantages reduce procurement costs while ensuring timely delivery. The rugged cast iron frame construction provides durability for demanding industrial environments.

XCMOTOR: Your Trusted Partner for High-Performance Industrial Motors

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in delivering comprehensive power equipment solutions tailored to industrial requirements. Our commitment to providing high energy efficiency, low energy consumption, and stable power equipment ensures optimal performance across diverse applications.

Our item portfolio encompasses engines extending from 200-3150 kW with voltage capabilities crossing 3.3 kV through 11 kV. The IP55 assurance lesson and separator appraisals of F/H guarantee solid operation in challenging situations. Speed ranges from 500-3000 RPM to oblige different application requirements.

Quality affirmation remains vital throughout our manufacturing process. Each engine experiences thorough testing counting accuracy component fabrication, progressive winding strategies, and comprehensive quality control strategies. This consideration of detail guarantees reliable execution and expanded benefit life.

We give devoted specialized support to pre-sales interviews, establishment direction, and continuous upkeep help. Our commitment expands past item conveyance to envelop total client fulfillment through responsive service and dependable technical expertise.

Conclusion

Optimizing engine execution requires a comprehensive understanding of working conditions, support conventions, and key acquisition choices throughout the gear lifecycle. Cutting-edge high-capacity engines, counting 4000 kw motor frameworks, can accomplish extraordinary effectiveness and unwavering quality when accurately indicated for stack profiles and natural conditions. The integration of advanced materials, optimized electromagnetic plan, and high-efficiency cooling frameworks decreases energy losses and warm stretch amid nonstop operation. Prescient and condition-based support procedures advance upgrade uptime by distinguishing potential disappointments some time recently they cause impromptu downtime. Cautious assessment of control necessities, proficiency appraisals, unwavering quality history, and add up to taken a toll of proprietorship empowers educated acquiring choices, guaranteeing long-term operational steadiness, diminished energy consumption, and maximized return on investment.

FAQ

1. What factors most significantly influence motor efficiency in industrial applications?

Design quality, operational conditions, and support hones fundamentally decide engine productivity. Premium materials, advanced cooling frameworks, and legitimate electrical associations keep up ideal execution levels. Normal upkeep counting oil, cleaning, and observing, avoids productivity corruption over time.

2. How do inverter-driven systems compare to traditional direct online starting methods?

Inverter-driven innovation gives exact speed control, diminished beginning current, and made strides vitality effectiveness compared to coordinate online beginning. These frameworks empower delicate beginning, speed variety, and control figure optimization, coming about in expanded engine life and diminished operational costs.

3. What are typical lead times for custom motor orders in industrial applications?

Custom engine fabricating ordinarily requires 8-12 weeks depending on details and complexity. Standard setups may dispatch inside 4-6 weeks, whereas profoundly customized arrangements require extra designing time. Early arranging and clear detail communication assist conveyance schedules.

Partner with XCMOTOR for Superior Motor Solutions

XCMOTOR delivers exceptional 4000 kw motor solutions designed for demanding industrial applications. Our comprehensive approach combines advanced engineering, quality manufacturing, and dedicated support services to ensure optimal performance throughout your motor's operational life. As a trusted 4000 kw motor supplier, we provide customized solutions meeting specific requirements while maintaining competitive pricing and reliable delivery schedules.

Contact our technical team at xcmotors@163.com to discuss your specific requirements and discover how our expertise can enhance your operational efficiency. Our commitment to original components from trusted brands, fast delivery services, 30-day return policies, and dedicated weekend support ensures your satisfaction with every purchase.

References

1. Industrial Motor Efficiency Standards and Performance Optimization Techniques, IEEE Industry Applications Society, 2023.

2. High-Power Electric Motor Design and Thermal Management Systems, International Journal of Electrical Engineering, 2023.

3. Predictive Maintenance Strategies for Large Industrial Motors, Mechanical Engineering Research Institute, 2023.

4. Energy Efficiency Analysis in High-Capacity Motor Applications, Power Systems Engineering Quarterly, 2023.

5. Advanced Cooling Technologies for Industrial Electric Motors, Thermal Management Engineering Review, 2023.

6. Total Cost of Ownership Models for Industrial Motor Procurement, Industrial Equipment Management Journal, 2023.