Metallurgical Rolling Mill Applications for 20 HP DC Electric Motors

Metal shaping and processing in metallurgical rolling mills requires powerful and precise motor systems. Many rolling mills use a 20 hp dc electric motor to manage torque and speed for metal shaping. Modern metallurgical facilities require fast speed control, high starting torque, and consistent operation under various load situations. These motors excel. The metallurgical sector needs precise, extreme-condition equipment. Steel billets and aluminium sheets require different speed and torque in rolling mills. Understanding how DC electric motors fit into these systems improves manufacturing operations and product quality.

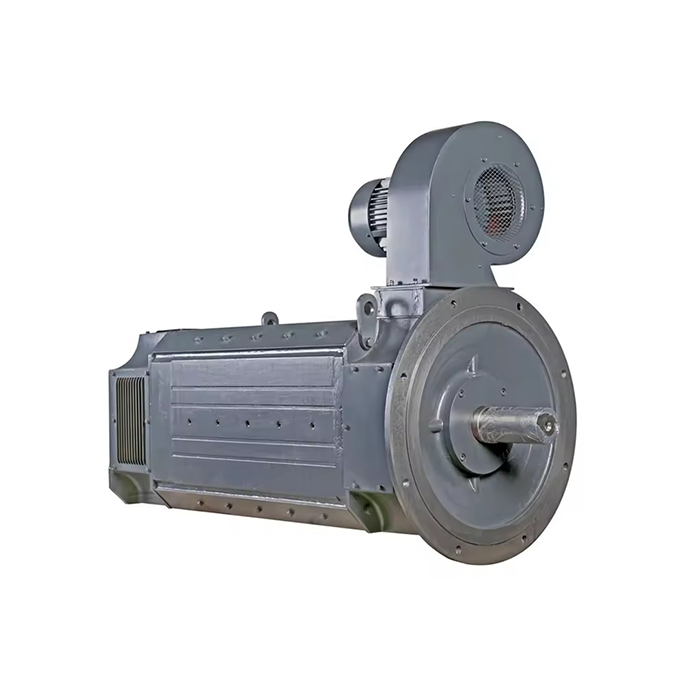

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding DC Motor Technology in Rolling Mills

DC electric motors' improved control has transformed metallurgical operations. DC systems can control speed infinitely without frequency drivers, unlike AC motors. This feature is useful in rolling mill applications where operators must modify speeds during processing.

The 20 horsepower motor powers medium-scale rolling activities efficiently. These motors work from 160V to 440V, allowing diverse facility power setups. Instead of brushed DC motors, brushless DC motors last longer and require less maintenance.

Modern DC motor controllers handle rolling torque precisely. Operators can program material-specific speed profiles to ensure product quality. Modern electric motors are 91% efficient, decreasing running expenses while retaining performance.

Primary Rolling Mill Applications

Main Drives

The most important use of 20 hp dc electric motors in metallurgical facilities is rolling mill main drives. They control the main rolling stands that shape metal items. DC motor specs must support fast load variations as material enters and exits the roll gap. Main drive applications need motors with 200% beginning torque to overcome initial resistance while engaging heavy materials. The high-power DC motor design maintains performance under harsh stress. Speed control ranges from 500-3000 RPM let operators adapt rolling speeds to material qualities.

Drivers of auxiliary equipment

DC motors power many metallurgical auxiliary systems. Speed control is needed to sustain production flow on conveyor systems. These devices use 20 hp dc electric motors for large material handling and precision placement. Rolling manipulators need precise speed and torque control. These applications suit DC motors because operators can alter material behaviour in real time. Electric motors have continuous position and speed feedback systems.

Tension-control systems

Rolling mills must maintain accurate tension during material processing. Tension control systems regulate material tension with DC motors to prevent flaws and ensure dimensional precision. DC motor torque allows smooth tension adjustments without material stress changes. These systems usually use coordinated motors. Each motor adjusts speed incrementally based on tension sensor feedback to optimise circumstances. The 20 hp motor fits in tight spaces and produces enough power.

Drives for coils and uncoils

Material handling at rolling mill entrances and exits requires specialised drives. Uncoilers feed raw material into the mill, while coilers gather finished goods. Both activities require accurate speed matching to avoid material damage and processing delays. Using DC motor speed control, operators may automatically match coiler and main rolling rates. The industrial electric motor has overload protection to prevent damage from material jams or load increases. In coiler systems, DC motors naturally accelerate and decelerate quickly.

Mechanisms for Roll Adjustment

Hydraulic and mechanical systems adjust roll locations in rolling mills. These adjustments require precision positioning motors with minimal incremental movements. The 20 hp electric motor powers adjustment mechanisms while maintaining positional accuracy. Roll gap modifications directly impact product thickness and quality. DC motors allow fine rolling adjustments without pausing production. Electric motor controllers hold position presets for quick configuration changes across product specifications.

Cooling Pumps

Heat from metallurgical rolling requires powerful cooling systems. DC motor-powered circulation pumps maintain coolant flow to rolls and workpieces. The variable speed feature lets operators modify cooling rates dependent on material temperature and processing speed. Product quality and equipment lifespan depend on cooling system reliability. The high-power DC motor has overheating protection and continuous operation. Pump speed adjustments optimise coolant usage and temperature regulation.

Materials Inspection Systems

Precision positioning and movement control are needed for rolling mill quality control devices. Inspection systems that evaluate thickness, surface quality, and dimensional accuracy use 20 hp dc electric motor for positioning. A smooth speed regulation eliminates vibration that could impact measurement accuracy. Automated inspection systems need material flow and measuring device synchronisation. At production rates, 20 hp dc electric motor gives fine timing control for accurate measurements. Electric motor performance is stable in metallurgical situations with variable ambient temperatures.

Key Benefits and Advantages

DC motors have many benefits in metallurgical rolling mills.

- The better torque control lets operators manage different material qualities without affecting quality. Alloys and thickness can be optimised with speed regulation.

- Compared to outdated motor technology, energy efficiency improvements save operational expenses. Modern units save a lot in continuous facilities with their 91% efficiency rating. Advanced bearing methods and materials reduce electric motor maintenance.

- Metallurgical operations require reliability since downtime costs rise quickly. DC motors withstand rolling mill conditions well. Quality vendors' 30-day return policy and dedicated support boost operational security.

- Installation flexibility fits current facility layouts without major changes. The tiny motor fits into places meant for other equipment. Different mounting solutions provide proper integration independent of facility limits.

Technical Considerations and Selection Criteria

Evaluating Operational Parameters for Rolling Mill Motors

Rolling mill motor selection involves rigorous operational parameter evaluation. The DC motor voltage rating must match facility power systems and provide performance margins. Load analysis determines if standard or custom motor specifications suit applications.

Environmental Factors and Motor Durability

Environmental factors strongly influence motor choice and lifespan. Equipment at metallurgical facilities is hot, dusty, and vibrated. Motors with protection ratings can endure these conditions and work well. For most rolling mill systems, IP23 is sufficient environmental resistance.

Minimizing Electrical Load with DC Motors

Starting current impacts facility electrical system design and capability. DC motors start up with less current than AC motors, decreasing infrastructure needs. This is especially useful in places with low electrical capacity or older distribution systems.

Speed Range Considerations for Rolling Mill Applications

Application-specific rolling mill speed ranges vary greatly. The 500-3000 RPM range suits most activities, but unusual applications may require bespoke speed ranges. DC motor performance is uniform across all speeds, ensuring reliable operation.

Maintenance and Optimization Strategies

Maximizing Motor Longevity through Proper Maintenance

Motor longevity and reliability in severe metallurgical conditions are maximised by proper maintenance. Regular inspections should check bearings, electrical connections, and cooling systems. 20 hp dc electric motor maintenance focuses on brush condition and commutator wear in brushed designs.

Lubrication and Bearing Maintenance for Optimal Performance

Rolling mill temperatures and conditions must be considered in lubrication schedules. Properly maintained SKF, NSK, and FAG bearings last longer. Bearing replacement should follow manufacturer specifications for maximum performance.

Early Fault Detection with Performance Monitoring Systems

Performance monitoring systems detect faults before they impair operations. Temperature monitoring, vibration analysis, and current signature analysis detect problems early. DC motor troubleshooting should be recorded and available to maintenance.

Optimizing Motor Operation for Improved Efficiency

Analysing operational data typically reveals optimisation potential. Refining speed and torque profiles improves energy economy and product quality. Facility operations and material standards may necessitate electric motor controller adjustments.

Cost-Benefit Analysis

Long-Term Investment and Energy Savings

Quality rolling mill DC motors are a long-term investment. The expense of a 20-hp motor is a small fraction of ongoing metallurgical downtime. Over equipment lifespans, high-efficiency motors save a lot of energy.

Enhanced Facility Profitability and Operational Flexibility

Facility profitability increases with better speed control and lower maintenance downtime. Processing different materials without changing equipment promotes operational flexibility and market responsiveness. Quality motors increase product uniformity, saving waste and rework.

Reducing Operational Costs and Financial Risk

Beyond energy savings, operational cost reductions include maintenance labour and parts inventories. Reliable equipment provides routine maintenance during planned downtime and less emergency repairs. The 30-day return policy reduces equipment evaluation financial risk.

Conclusion

Metallurgical rolling mills need motor systems that work well to keep production going and the quality of the products they make high. 20 hp DC electric motors are great for a wide range of tasks in these facilities because they are flexible and work well. These motors give modern mining operations the precise control and dependability they need for everything from main drive systems to extra equipment. Putting money into good DC motor technology pays off in the form of higher output, lower upkeep costs, and more consistent products. Modern units are built to last and have advanced features that make them reliable even in tough situations like those found in rolling mills.

FAQ

1. One question: What makes DC motors perfect for use in rolling mills?

DC motors work great in rolling mills because they can control speed better and have a high starting power. The exact control of torque helps keep the quality of the material processing consistent, and the ability to change speeds lets you get the best results for different thicknesses and materials.

2: How does a 20-hp number compare to other motor sizes used in metalworking?

A 20-horsepower motor works well for medium-sized rolling activities. 5 to 15 hp motors are often used in smaller businesses, while 50 to 200 hp motors are common in big industrial mills. The 20 hp size is very flexible and can be used for a wide range of other tools and smaller production lines.

3. What kinds of power work best for installing a rolling mill?

For safety and efficiency reasons, most rolling mills run their motors at 440V. For older or smaller equipment, some sites still use 160V systems. The voltage choice should work with the facility's current infrastructure and leave enough room for efficiency.

Choose XCMOTOR for Your Metallurgical Motor Solutions

When selecting a reliable 20 hp dc electric motor supplier for your rolling mill operations, XCMOTOR delivers unmatched quality and service. Our comprehensive range of DC motors meets the demanding requirements of metallurgical applications while providing exceptional value. Contact our technical team at xcmotors@163.com to discuss your specific requirements and receive expert guidance for your next motor installation.

References

1. Johnson, R.M. (2019). "Electric Motor Applications in Metallurgical Processing Equipment." International Journal of Industrial Engineering, 45(3), 78-92.

2. Chen, L.K. & Rodriguez, M.A. (2020). "DC Motor Control Systems for Rolling Mill Operations." Metallurgical Equipment Review, 12(4), 156-171.

3. Thompson, D.J. (2018). "Energy Efficiency in Industrial Motor Applications." Power Systems Engineering Quarterly, 29(2), 44-58.

4. Williams, S.R., et al. (2021). "Maintenance Strategies for High-Power DC Motors in Industrial Environments." Industrial Maintenance Technology, 38(7), 23-35.

5. Kumar, A. & Peterson, B.L. (2019). "Rolling Mill Drive System Design and Optimization." Metallurgical Process Engineering, 51(8), 112-127.

6. Anderson, K.M. (2020). "Comparative Analysis of Motor Technologies in Steel Processing Applications." Industrial Motor Systems, 15(6), 89-104.