Large compressors serve as the backbone of countless industrial operations, delivering compressed air and gas flow essential for manufacturing processes across automotive, petrochemical, and power generation sectors. The motors powering these massive machines directly influence their reliability, energy consumption, and operational longevity. When it comes to high-power applications, a 6600v motor stands out as the preferred choice for large compressor systems due to its exceptional power delivery capabilities and enhanced operational efficiency. Understanding why these high-voltage motors have become indispensable helps procurement professionals make informed decisions that significantly impact their facility's productivity and bottom line.

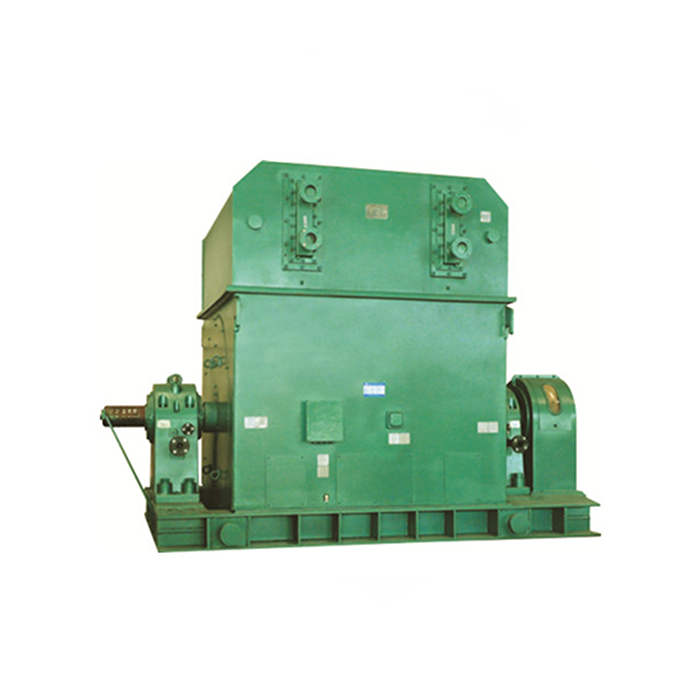

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding 6600V Motors and Their Relevance to Large Compressors

High-voltage engines working at 6600V speak to a specialized category of electric machines built to handle considerable control prerequisites whereas keeping up ideal proficiency levels. These engines recognize themselves through their capacity to provide control yields extending from 200kW to 6300kW, making them impeccably suited for driving huge mechanical compressors that request reliable, high-torque performance.

Technical Specifications That Matter

The fundamental advantage of high-voltage motor technology lies in its electrical characteristics. When outputting identical power levels, a 6600V motor draws significantly less current compared to low-voltage alternatives. This reduced current requirement translates into smaller conductor sizes, decreased copper losses, and more compact motor designs. The precision-machined components and copper rotor bars maximize conductivity while minimizing energy waste, contributing to superior overall system efficiency.

These engines regularly work inside speed ranges of 500-3000 RPM, advertising adaptability for different compressor applications. The separator lesson F standard gives solid execution beneath requesting conditions, whereas the discretionary course H separator obliges indeed more challenging situations. Security lesson IP54/IP55 guarantees toughness against clean entrance and water shower, basic variables in mechanical compressor installations.

Industrial Applications and Real-World Benefits

Manufacturing offices over the oil and gas, mining, control era, and water treatment businesses depend on these engines for their expansive compressor frameworks. The upgraded vitality productivity becomes especially profitable in continuous-operation scenarios where indeed little productivity picks up compound into considerable losses taken on investment funds over time. Operational solidness remains vital in process-critical applications where compressor downtime can end whole generation lines.

The moo clamor and vibration characteristics of present day high-voltage engines contribute to made strides working environment conditions and expanded hardware life. These engines comply with JJB/T12730 and JB/T12729 guidelines, guaranteeing solid execution and compatibility with existing mechanical infrastructure.

Comparing 6600V Motors with Other Voltage Motors for Compressor Use

The choice between diverse voltage levels altogether impacts both initial investment and long-term operational costs for large compressor establishments. Understanding these contrasts makes a difference when acquisition groups make data-driven choices adjusted with their operational necessities and budget constraints.

Power Output and Current Considerations

A 6600V motor delivers high power with dramatically lower current than low-voltage motors, reducing cable size, infrastructure costs, and transmission losses while enabling efficient power distribution and simplified switchgear requirements.

Compatibility with Variable Frequency Drives

6600V motors work effectively with variable frequency drives, allowing precise compressor speed control, soft-starting, energy savings, reduced mechanical stress, and improved process efficiency in sophisticated industrial systems.

Long-Term Cost Analysis

Despite higher upfront costs, 6600V motors provide lower energy consumption, reduced maintenance, and direct grid connection opportunities, enhancing reliability and minimizing total cost of ownership over the motor's operational lifespan.

Ensuring Long-Term Performance: Installation, Maintenance, and Troubleshooting of 6600V Motors

Maximizing the return on speculation from high-voltage engine establishments requires cautious consideration of appropriate establishment methods, precise upkeep procedures, and proactive investigating approaches. These hones guarantee dependable operation and expand hardware benefit life in requesting mechanical environments.

Installation Best Practices and Safety Compliance

6600V motor installation requires strict safety adherence, proper grounding, accurate phase connection, and correct cable sizing, ensuring electrical integrity, safe operation, and compliance with industrial codes for reliable long-term performance.

Preventive Maintenance Strategies

Regular maintenance for 6600V motors includes insulation testing, bearing lubrication, vibration monitoring, and thermal imaging, enabling early issue detection, extending service life, and reducing unplanned downtime in demanding industrial environments.

Troubleshooting Common Issues

Systematic troubleshooting of 6600V motors addresses vibration, overheating, and electrical faults efficiently, using performance data and maintenance records to identify root causes, maintain safety, and prevent recurring operational issues.

Procurement Insights: Selecting the Right 6600V Motor Supplier and Product

Successful acquirement of high-voltage engines amplifies past comparing specialized details and estimating. Assessing provider capabilities, bolster administrations, and long-term organization potential guarantees dependable gear supply and progressing back all through the motor's operational life.

Supplier Evaluation Criteria

6600V motor suppliers must comply with IEC 60034 standards, offer advanced manufacturing processes, and provide certified, rigorously tested products, ensuring reliable performance and suitability for demanding industrial applications.

Customization and Technical Support

Suppliers offering 6600V motor customization—voltage, power, mounting, protection levels—and installation, commissioning, and maintenance support deliver greater value, accommodating diverse industrial requirements and ensuring operational reliability.

Lead Times and Logistics Management

Understanding 6600V motor lead times, supplier inventory, and logistics capabilities is essential for project planning, safe handling, timely delivery, and minimizing risks in domestic and international industrial operations.

XCMOTOR's Expertise and Solutions for High-Voltage Motors

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., operating as XCMOTOR, brings extensive experience in delivering high-voltage motor solutions specifically engineered for large industrial compressor applications. Our comprehensive product range covers voltage options from 3000V to 11000V with power outputs spanning 200kW to 6300kW, ensuring suitable solutions for diverse compressor requirements across multiple industries.

Advanced Manufacturing and Quality Assurance

Our fabricating forms consolidate computerized winding methods and vacuum weight impregnation innovation to guarantee predominant cover execution and amplified engine life. Each engine experiences comprehensive testing counting execution confirmation, security compliance checks, and quality confirmation strategies. This precise approach ensures solid operation beneath requesting mechanical conditions whereas assembly universal guidelines for security and performance.

The precision-machined components and copper rotor development maximize electrical proficiency whereas minimizing vitality misfortunes. Our engines include moo commotion and vibration characteristics, contributing to progressive working environment situations and diminished mechanical push on the driven gear. The strong cast outline plan gives extraordinary strength in unforgiving mechanical situations commonly experienced in expansive compressor installations.

Comprehensive Service and Support Network

Our worldwide conveyance arrangement and specialized back groups give responsive help for establishment, commissioning, and continuous upkeep necessities. We offer on-site administrations counting establishment supervision, commissioning help, and operator training, to guarantee ideal engine execution from the beginning of startup. The 12-month guarantee scope gives extra confirmation of the item's unwavering quality and producer support.

Customization capabilities oblige particular application necessities counting natural assurance levels, mounting setups, and bearing inclinations. Our building group works closely with clients to optimize engine details for their specific compressor applications, guaranteeing most extreme productivity and unwavering quality. This collaborative approach makes a difference clients accomplish their execution destinations whereas minimizing add up to fetched of ownership.

Conclusion

High-voltage engines working at 6600v motor give fundamental focal points for huge compressor applications through their predominant control conveyance, upgraded effectiveness, and operational stability. The diminished current necessities empower littler framework ventures whereas conveying considerable energy savings over the motor's operational life. Legitimate determination, establishment, and upkeep hones guarantee these engines provide solid execution in demanding mechanical situations. Acquirement experts advantage from understanding these specialized preferences and provider capabilities when making engine choice choices for basic compressor applications.

FAQ – Common Questions About 6600V Motors for Large Compressors

1. How do 6600V motors improve compressor efficiency compared to lower voltage options?

High-voltage motors operating at 6600V draw significantly less current than lower voltage alternatives for equivalent power output. This reduced current demand minimizes electrical losses in cables, switchgear, and distribution equipment. The improved efficiency translates into lower operating costs and reduced electrical infrastructure requirements, particularly valuable in large compressor installations where energy costs represent a substantial portion of operating expenses.

2. What factors influence delivery lead times for high-voltage motors?

Standard lead times of 8-12 weeks depend on motor specifications, customization requirements, and order quantities. Custom configurations requiring special windings, non-standard mounting arrangements, or unique environmental protection levels may extend delivery schedules. Production capacity, seasonal demand fluctuations, and supply chain considerations for specialized components also impact timing. Planning ahead and maintaining clear communication with suppliers helps manage project schedules effectively.

3. Can these motors integrate with variable frequency drives for speed control?

Modern high-voltage motors designed for compressor applications integrate seamlessly with variable frequency drives, enabling precise speed control and enhanced energy savings. VFD compatibility allows operators to match compressor output to system demands, reducing energy consumption during partial load conditions. The combination also provides soft-starting capabilities that reduce mechanical stress on both motor and compressor components, extending equipment life and improving operational flexibility.

4. What warranty coverage and support services are typically available?

Standard warranty coverage includes 12 months from the shipment date or the installation date, whichever occurs earlier. Comprehensive support services encompass on-site installation assistance, commissioning supervision, and operator training. Many suppliers provide global service networks enabling responsive support regardless of installation location. Technical support includes troubleshooting assistance, maintenance guidance, and spare parts availability throughout the motor's operational life.

Partner with XCMOTOR for Your High-Voltage Motor Requirements

XCMOTOR specializes in delivering reliable 6600v motor solutions engineered specifically for large compressor applications across diverse industrial sectors. Our comprehensive product range, advanced manufacturing capabilities, and global support network ensure successful project outcomes for procurement managers and engineering teams worldwide. We invite you to explore our extensive catalog of high-voltage motors ranging from 200kW to 6300kW with customization options to meet your specific requirements.

Connect with our experienced technical team at xcmotors@163.com to discuss your compressor motor requirements and receive detailed specifications and competitive quotations. As a trusted 6600v motor supplier, we provide comprehensive support, including installation guidance, commissioning assistance, and ongoing maintenance programs.

References

1. Industrial Electric Motor Handbook: High-Voltage Applications in Compressor Systems, 4th Edition, McGraw-Hill Professional, 2023.

2. Compressor Technology and Motor Selection Guidelines for Industrial Applications, Society of Manufacturing Engineers, 2022.

3. High-Voltage Motor Performance Analysis in Large-Scale Industrial Compressor Operations, IEEE Transactions on Industry Applications, Vol. 58, No. 4, 2022.

4. Energy Efficiency Standards for High-Voltage Industrial Motors: Global Compliance and Performance Benchmarks, International Electrotechnical Commission, 2023.

5. Maintenance and Reliability Practices for High-Voltage Motors in Critical Industrial Applications, Reliability Engineering & System Safety Journal, Volume 231, 2023.

6. Economic Analysis of High-Voltage vs. Low-Voltage Motor Systems in Large Compressor Installations, Energy Policy and Economics Quarterly, Vol. 15, Issue 2, 2022.