Choosing the right high-power motor for industrial use can have a big effect on the output and prices of running your facility. There is no better industrial power option than a 4000 kW motor, which delivers top-notch performance in even the toughest situations. These tough tools work great in heavy-duty settings where dependability, efficiency, and steady power output are important. The 4000 kW motor is the best choice for makers, power plants, and process businesses that need the highest levels of performance. Its advanced engineering and tried-and-true technology make it the best choice.

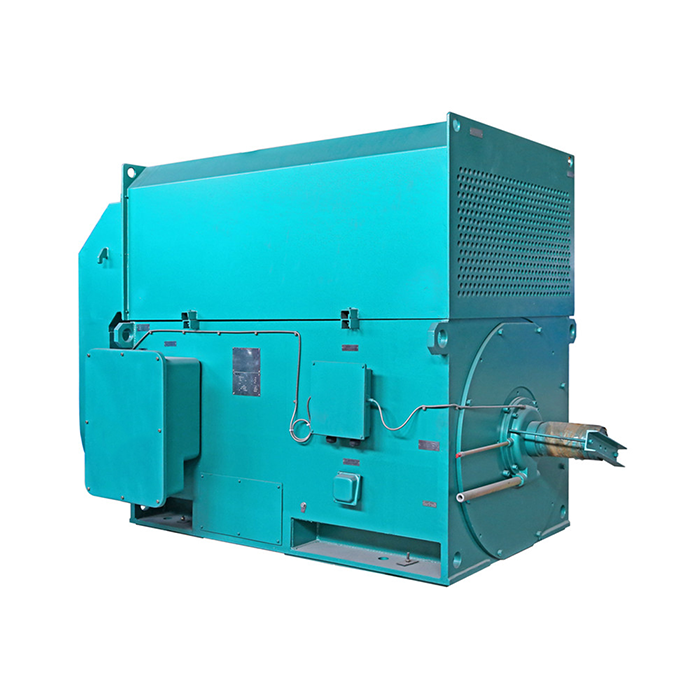

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

How to Understand the 4000 kW Motor

Industrial high-power motors are an important part of many modern industrial and process operations. Knowing what they can do helps businesses make smart choices about where to spend in power facilities.

What is a 4000 kW Motor?

A 4000 kW motor is an industrial-grade electric machine that can produce about 5,364 horsepower of mechanical power. These motors usually work with voltages between 3000V and 11000V, so they can work with a variety of industrial electrical systems. The strong construction has cast iron frames, blades that are perfectly balanced, and advanced cooling systems that are made to work continuously in harsh conditions. Large-scale manufacturing facilities, mining activities, steel mills, power plants, and oil refineries are all places where a lot of mechanical power is needed.

How Does a 4000 kW Motor Work?

The basic workings depend on electromagnetic principles, which say that magnetic fields can change electrical energy into mechanical energy. The spinning magnetic fields from the stator windings cause current to flow through the rotor, which makes power for mechanical output. Modern designs use high-tech shielding systems, usually Class F or H, which make sure they work reliably even in very hot or cold circumstances. Precision-engineered parts, such as SKF, NSK, or FAG bearings, make operation easy and reduce sound to a minimum. PT100 sensors in the stator windings and bearings keep an eye on the temperature to make sure the motor works at its best and avoids damage from burning.

Why using a 4000 kW motor is a good idea

Electric motors with a lot of power have many benefits that make them essential for industrial work. These benefits go beyond just providing power; they also include making operations more efficient and reliable.

Pros of Motors with a Lot of Power

When industrial sites use high-capacity electric motors, they get a number of important benefits. Because they are built to last and use high-quality parts that can handle rough conditions, these motors are very reliable.

- Increased working life: With proper upkeep, modern materials and precise production make products that last longer than 20 years.

- Very little vibration: To keep things running smoothly, well-balanced wheels and good bearings are used. This keeps linked equipment from wearing out.

- Better scores for efficiency: Modern versions are more than 95% efficient, which means they use less electricity and cost less to run.

- Maintenance made easier: Electric motors only need basic maintenance like cleaning and regular checks, so they don't need complicated combustion system service.

All of these benefits work together to lower the total cost of ownership while increasing production uptime and dependability.

Noise Levels and How to Install It

Modern 4000 kW motors have noise-reduction methods that keep sound levels below 85 dB(A), so they can be used in places with strict noise rules. For installation to go smoothly, the base needs to be properly prepared. Usually, concrete pedestals are used that are made to handle dynamic loads and isolate vibrations. Electrical links must meet high-voltage safety standards, which means that they can only be set up by trained experts. Enough air room is needed for the cooling system to work at its best, and positioning steps make sure that the system can connect smoothly to driven equipment. Protection class IP54 protects against dust and water spray, making it good for most industrial settings.

Getting a 4000 kW Motor

To get the right high-power motor, you need to know what the provider can do, how much they charge, and what kind of support services they offer. To get the best value and long-term happiness from the buying process, it needs to be carefully evaluated.

Where Can I Get a 4000 kW Motor?

Reliable sellers usually keep a lot of stock and can help with technical issues. Distributors of industrial motors offer local help and faster shipping times, while makers give you direct access to professional support and unique setups. Online shopping sites make it easier to compare prices and make sure that the specs are correct, but direct relationships with suppliers are often better for big purchases. International shipping options give you access to providers around the world, but for ongoing support needs, it's still important to think about local service choices.

How to Figure Out the Price of a 4000 kW Motor

The price of a motor depends on a number of things, such as its power grade, voltage requirements, safety class, and gear designs. When compared to unique designs, standard models in the 200–3150 kW range offer economies of scale. Pricing may be affected by voltage needs between 3000V and 11000V, depending on how complicated the insulation system is. Premium bearings, such as those made by SKF or NSK, add value because they last longer. The warranty period is usually between 12 and 24 months, but for important uses, it can be expanded. Payment terms often work with the steps of buying capital equipment, and approved buyers can even get finance options.

Top Manufacturers and Brands

There are well-known companies in the industrial motor market that have a history of success in high-power uses. Brand choice affects the quality of the product, the availability of help, and how reliable it is in the long run.

Brands of the Best 4000 kW Motors

Leading makers show their skill by having a wide range of products and a lot of experience with different applications. Well-known names put a lot of money into research and development, which leads to cutting-edge designs that keep up with changing needs in the industry. Customer reviews are a great way to find out about how well a product or service works in real life. Product quality and safety are ensured by following manufacturing standards, such as JB/T 12730 and JB/T 12729. Customization is possible with OEM services for certain uses, but standard goods have been shown to be better in terms of speed and availability.

Introducing the company and its products

XCMOTOR, or Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., is an expert in offering complete power equipment options for business uses. Our promise is to provide motors with stable power output that are high in efficiency and low in consumption. The company has strict quality standards and only buys parts from well-known names to make sure they are reliable. Fast delivery services include free shipping on all items, and you can return items within 30 days, so you can buy with trust. Dedicated support is available on weekends to make sure that customers can get help when they need it. Our professional knowledge includes advice before the sale, help with installation, and support after the sale for the whole span of the equipment.

Conclusion

High-power industrial operations demand reliable, efficient motors that deliver consistent performance under demanding conditions. The 4000 kW motor represents an optimal solution for facilities requiring substantial mechanical power with minimal maintenance requirements. Advanced engineering, quality components, and proven reliability make these motors essential for modern industrial applications across manufacturing, power generation, and process industries.

Frequently Asked Questions

Q1: What is the typical lifespan of a 4000 kW motor?

A: With proper maintenance, a 4000 kW motor typically operates reliably for 20-25 years. The actual lifespan depends on operating conditions, maintenance quality, and load factors. Regular bearing lubrication, thermal monitoring, and periodic inspections significantly extend service life.

Q2: How often does a 4000 kW motor require maintenance?

A: Routine maintenance includes monthly visual inspections, quarterly bearing lubrication, and annual comprehensive examinations. Critical components like bearings may require replacement every 5-10 years depending on operating hours and conditions. Temperature sensors and insulation testing help identify potential issues before failures occur.

Q3: What shipping options are available for international orders?

A: International shipping typically involves sea freight for motors of this size due to weight and dimensions. Delivery times range from 4-8 weeks depending on destination. Professional packaging ensures protection during transport, while documentation includes technical specifications and installation guidelines.