explosion proof electric motor

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:185-1800 kW

Application:fans, compressors, water pumps, crushers, winches, centrifuges, cutting machine tools, transportation machinery.

Advantage: Excellent performance, reliable operation.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

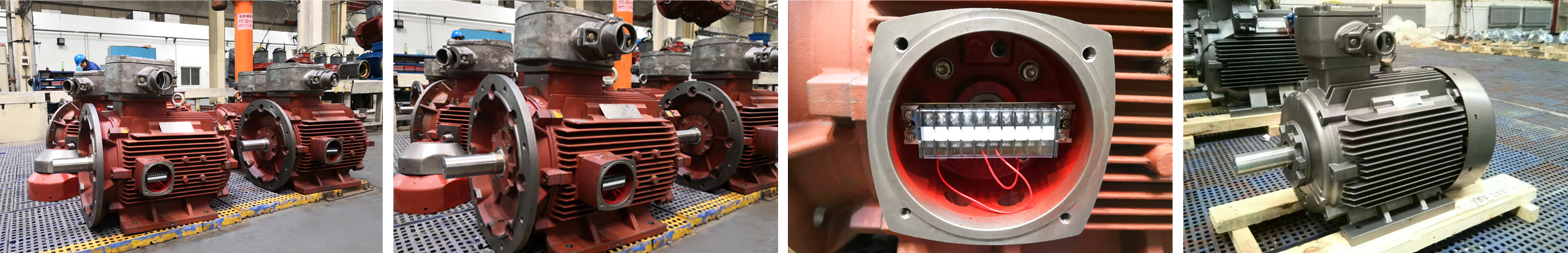

YB2-HV High Voltage Explosion Proof Electric Motor

Even in the most demanding industrial settings, your activities will function flawlessly thanks to the YB2-HV series' combination of strong explosion proof electric motor design and cutting-edge high-voltage technology. This motor is long-lasting and expertly engineered to deliver the reliable power your business needs.

Description

Our high-voltage YB2-HV motors are made especially for dangerous areas where people's safety cannot be compromised. These motors have a high-end build, sophisticated insulating systems, and a track record of dependability in challenging settings. You retain optimal performance in a variety of industrial areas while receiving excellent protection against environmental issues.

Product Specifications

| Item | Specification |

|---|---|

| Series | YB2-HV |

| Voltage Range | 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%, 11000V±5% |

| Power Range | 185-1800 kW |

| Protection Rating | IP54 (IP55 for outdoor models) |

| Insulation Class | Class F (155℃ temperature resistance) |

| Speed Stability | ≤0.5% fluctuation rate |

| Operational Reliability | >99.7% |

Product Details

The motor incorporates Class F insulation materials treated with vacuum pressure impregnation technology. This ensures insulation breakdown voltage exceeding 30kV. The rotor construction uses high-permeability silicon steel sheets with precision dynamic balancing for smooth operation.

Real-time monitoring is made possible by overvoltage protection devices and high-voltage zero-sequence current transformers. To avoid harm, the device immediately disconnects when voltage variations above ±10%.

Production Process

Our manufacturing follows strict quality protocols. Each explosion proof electric motor undergoes comprehensive testing including 1200-hour salt spray corrosion testing. The casing receives triple protection treatment with phosphating, epoxy resin spraying, and wear-resistant coating.

Windings feature sealed end caps and labyrinth ventilation structures. High-efficiency forced ventilation systems maintain optimal temperatures even in extreme conditions.

Application Scenarios

Perfect for various industrial applications:

- Fans and compressors in chemical plants

- Water pumps in offshore facilities

- Crushers and winches in mining operations

- Centrifuges in processing facilities

- Cutting machine tools in manufacturing

- Transportation machinery systems

Why Choose XCMOTOR

With over 20 years of experience, we maintain partnerships with 30+ leading motor manufacturers including ABB, Siemens, and Wolong. You benefit from our expertise in selecting high-efficiency, low-consumption motors that deliver stable power.

Our Advantages:

- Original products from trusted brands only

- Fast delivery with free shipping

- 30-day return policy

- Dedicated support including weekends

- Competitive pricing with optimal production cycles

- Customized transportation solutions

Qualification Certifications

All products meet international standards with certifications including:

- CCC and CE certification

- ISO9001:2000 quality system certification

- Railway CRCC certification

- CQC quality management certification

FAQ

Q: What makes this motor suitable for hazardous environments?

A: Our explosion proof electric motor features IP54/IP55 protection, triple-coated casing, and sealed components that resist corrosive environments and prevent ignition sources.

Q: How does the high-voltage design benefit operations?

A: The optimized electromagnetic design handles voltage fluctuations while maintaining speed stability. Advanced insulation prevents breakdown even during power grid anomalies.

Q: What maintenance is required?

A: Routine maintenance involves cleaning the cooling system and bearing grease replenishment every 3000 hours. Modular design reduces maintenance time by 50%.

Q: Can bearings be customized?

A: Yes, we can replace standard bearings with SKF, NSK, or FAG bearings according to your specific requirements.

Contact Us

For assistance in choosing the ideal explosion-proof electric motor for your application, our staff is available. Get in touch with us right now for affordable prices and knowledgeable advice.

Email: XCMOTORs@163.com">xcmotors@163.com

For dependable, certified explosion proof electric motor solutions that maintain the safety and effectiveness of your operations, rely on XCMOTOR.