When picking the correct YBX5 explosion-proof motor for your facility, you need to think about the voltage needs, power ratings, environmental conditions, and safety certifications. The YBX5 series can handle voltages from 380V to 1140V and power outputs from 0.55 to 630 kW, making it useful for a wide variety of industrial uses. Some important things to think about include making sure that the motor specifications fit your operating needs, knowing what explosion-proof ratings (Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb) mean, and making sure that you follow industry standards for dangerous situations.

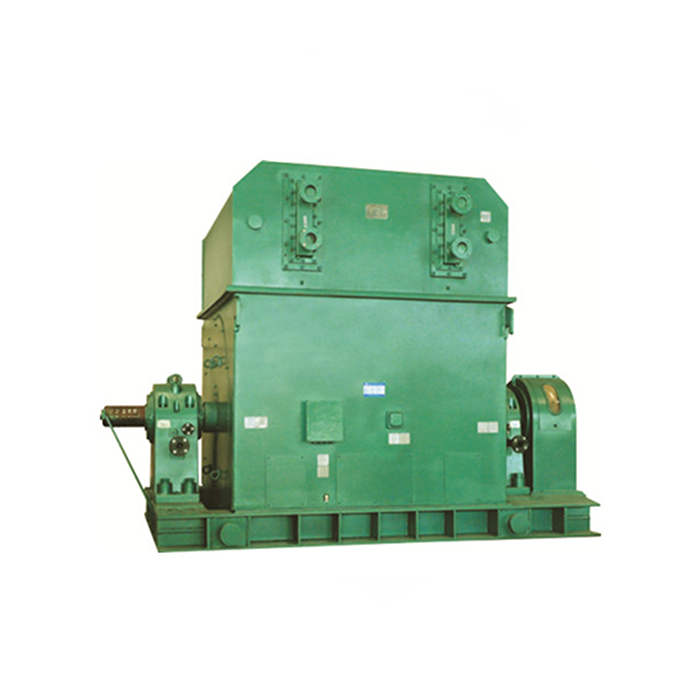

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Getting to know the YBX5 Explosion-Proof Motor Specs

To choose the right explosion-proof motor, you need to know the technical details that affect performance and safety. The YBX5 series is a superior engineering design made for dangerous places where explosive gas combinations are a big concern.

YBX5 motors can work with different industrial power systems since they can handle several voltages, such as 380V, 660V, 415V, 380/660V, and 660/1140V. This adaptability makes it easy to add to existing electrical systems in the petroleum, chemical, mining, metallurgy, electric power, and equipment sectors.

The power output spans from 0.55 kW to 630 kW, making it possible to use these devices for anything from tiny process pumps to big industrial compressors. The squirrel cage design guarantees dependable performance, and the completely enclosed, self-fan cooling system keeps the machine running at the right temperature even when it has to run for a long time.

For mining applications, explosion-proof marks Ex d I Mb are very important. For gas group classifications, Ex d IIB T4 Gb and Ex d IIC T4 Gb are also very important. These certifications make sure that the equipment can be used safely in places where flammable gasses could be present. The IP55 protection level keeps dust and water out of the inside parts, while the insulation class F grade can handle temperatures up to 155°C.

The strong cast iron frame makes the structure very strong and helps it cool off quickly. Customers may choose high-quality bearings from SKF, NSK, or FAG to meet their needs. This will make the bearings last longer and need less maintenance.

Putting YBX5 Explosion-Proof Motors next to other models

When looking at several motor possibilities, it's easier to choose the best one for a certain need if you know the differences between the different series. The YBX5 explosion-proof motor has a number of improvements over older models like the YBX3.

Performance attributes are a major way to tell the difference. The YBX5 gets IE5 efficiency class ratings, which means it uses a lot less energy than regular motors. This better performance means that the motor will have fewer operating costs and a less effect on the environment during its lifetime.

Explosion-proof motors are different from regular motors because they include extra safety measures. Standard motors may create sparks or too much heat that might start a fire. Explosion-proof motors, on the other hand, keep any internal ignition sources within reinforced casings. The YBX5 has flame-proof joints and a stronger structure that prevents explosions from spreading to the air around it.

Cost-benefit analysis shows that although while explosion-proof motors cost more to buy at first, the safety advantages and compliance with regulations make the extra cost worth it in dangerous places. The YBX5's longer service life and lesser maintenance needs frequently mean that it costs less to purchase than other options.

There are other ways to start the YBX5, such as Direct-On-Line (DOL), Star-Delta, and soft start. This gives you more choices for different types of loads. It can work in a wide variety of temperatures, from -20°C to +40°C, and at heights of up to 1000m above sea level.

Uses and advantages of YBX5 explosion-proof motors

YBX5 explosion-proof motors are important parts in many sectors where safety and dependability are very important since they may be used in many different ways. Knowing about particular use cases will help you figure out where these motors are most useful.

In petrochemical plants, volatile hydrocarbon vapors make it possible for explosions to happen all the time. The YBX5's explosion-proof construction prevents sparks from within the machine from lighting up gasses around it. This makes it safe to use pumps, compressors, and mixing equipment. The motor is built to last in settings where chemicals are corrosive and temperatures change a lot.

Mining operations have specific problems with flammable dust and gas build-up. Motors that can work safely in small locations where ventilation may not be good are needed for underground applications. The Ex d I Mb rating is designed for mining situations and makes sure that the equipment meets strict safety standards.

Offshore oil rigs work in rough maritime settings where salt spray and bad weather may damage equipment. The IP55 protection grade keeps moisture from getting inside, and the materials that don't rust make the device last longer in these tough situations.

Explosion-proof motors are used in factories that work with paints, solvents, or other combustible compounds to keep things safe. The YBX5 is great for spray booths, solvent recovery systems, and chemical mixing since it can hold internal ignition sources and still work reliably.

Here are the main safety and compliance advantages that make YBX5 motors necessary in dangerous places:

- Compliance with regulations: ATEX certification shows that a company follows worldwide standards for explosion protection. This makes it easier to get regulatory permission and insurance coverage, and it shows that the company cares about safety at work.

- Danger Reduction: The design of flame-proof enclosures keeps ignition sources within from reaching the outside, which lowers the danger of explosions and keeps people and equipment safe.

- Operational Continuity: Reliable performance in tough settings reduces unexpected downtime and maintenance delays, keeping production plans and profits on track.

- Environmental Protection: Strong construction cuts down on waste from having to replace equipment too soon, and high-efficiency operation uses less energy and leaves a smaller carbon impact.

These all-around safety measures take care of important operating issues and make sure that the equipment will work reliably for a long time in tough industrial settings.

How to Buy YBX5 Explosion-Proof Motors

To get the correct explosion-proof motor, you need to carefully choose a source and organize your purchase to make sure the product is of good quality and arrives on time. Knowing what buying choices are accessible makes the process of getting things easier.

Authorized distributors provide the technical knowledge and local assistance that are necessary for choosing and installing a motor correctly. These partners know the rules in their area and can help with developing specifications to make sure the motors you choose match both application needs and compliance criteria.

When looking at suppliers, think about how well they can help you with technical issues, how easy it is to get replacement parts, and how far their service network reaches. It takes particular understanding to install and maintain explosion-proof motors, thus it's important for suppliers to have this knowledge for long-term success.

The paperwork needed for explosion-proof equipment is typically more than what is needed for regular motors. Suppliers should provide full certification packages that include ATEX declarations, installation instructions, and maintenance tips. This paperwork helps the motor follow the rules and run safely throughout its whole service life.

Explosion-proof motors usually take longer to make than regular motors because they need unique manufacturing processes and quality testing. Planning procurement efforts well in advance keeps projects on track and makes sure that equipment is available when it's required.

When shipping, you need to think about how to package things so that sensitive parts are safe and how to follow hazardous materials rules when they apply. Reputable suppliers plan logistics to reduce damage during handling and make sure that projects are delivered on schedule.

Introducing Our Brand and What We Do

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. (XCMOTOR) is the best company for power equipment solutions since it has both technological know-how and great customer service. Our dedication to quality and dependability has helped us build solid relationships with industrial customers in a wide range of fields.

We concentrate on making high-efficiency, low-energy motors that provide steady power in tough situations. The YBX5 explosion-proof motor is a great example of how committed we are to safety and performance. It has sophisticated design characteristics that go above and beyond what is required by the industry.

Quality assurance starts with choosing the right components, using only parts from well-known companies to make sure they work reliably. Our strict production methods include precision machining, high-quality winding and insulation, strict quality control inspections, and thorough performance testing in environments that mimic dangerous situations.

Our approach to commercial partnerships is different since we focus on great customer service. We provide specialized support seven days a week, including on weekends, so you can always get help when you need it. Our technical staff can help you choose the right motor, install it, and solve problems with it during its life.

Some of the benefits of our business are that we ship all items for free and quickly, we have a 30-day return policy for open orders, and we provide full assistance after the transaction. This promise to make customers happy develops long-term relationships built on trust and shared success.

The combination of high-quality parts, fast shipping, easy returns, and devoted support adds value that goes beyond the original purchase and helps customers run their businesses and make money over the long term.

Conclusion

To choose the right YBX5 explosion-proof motor, you need to carefully look at its technical specs, safety approvals, and application needs. The YBX5 series is a great choice for uses that need to be safe in dangerous environments because it has a wide range of voltage and power levels, is well-built, and has safety features that have been shown to work. Understanding the differences between motor types, checking out the skills of the provider, and thinking about the long-term operating benefits will help you make the best choice and make the implementation go smoothly. Because XCMOTOR is knowledgeable and dedicated to quality, they offer the professional help and trustworthy goods that are needed for safe and effective work in tough industrial settings.

Questions People Ask Often

1. What are the best things about using a YBX5 motor that won't explode?

A: The YBX5 motor has better safety features, such as a flame-proof housing design that keeps sparks from inside the motor from hitting the outside air. This product is both highly efficient (IE5 class) and well-built, so it can work reliably in dangerous places while also using less energy and needing less upkeep.

2. What makes a YBX5 motor different from a normal motor?

A: The strengthened casings, flame-proof joints, and special building materials used in YBX5 motors make them impossible to start in dangerous environments. Unlike regular motors, they go through a lot of testing and licensing to make sure they can be used safely in places where there may be dangerous gases or dust that can catch fire.

3. What kinds of safety rules do YBX5 motors follow?

A: YBX5 motors meet foreign safety standards, such as the ATEX standard for use in dangerous environments and the CCC standard for use in China. They have marks that say they are explosion-proof (Ex d I Mb for mine uses and Ex d IIB T4 Gb, Ex d IIC T4 Gb for different gas group classes), which makes sure that they follow the rules in many different industries.

Choose XCMOTOR for Your Explosion-Proof Motor Requirements

XCMOTOR is ready to help you with your explosion-proof motor needs by giving you complete solutions that are made to fit your needs. As a reputable ybx5 explosion-proof motor supplier, we make sure projects go well by combining technical know-how with great customer service.

Our team of expert engineers can help you choose the right motor, write the specifications, and plan the installation so that your facility works better and is safer. Because we know how important explosion-proof products are, we offer the expert help that is needed for a successful execution.

Ready to enhance your plant's safety and operational reliability? Contact us at xcmotors@163.com to discuss your YBX5 explosion-proof motor requirements and receive a personalized quotation. Our technical specialists will work with you to identify the optimal YBX5 configuration for your specific application.

References

- International Electrotechnical Commission. "Explosive Atmospheres - Part 1: Equipment Protection by Flameproof Enclosures 'd'" IEC 60079-1:2014.

- National Institute for Occupational Safety and Health. "Criteria for a Recommended Standard: Working in Confined Spaces." DHHS (NIOSH) Publication No. 80-106, 1979.

- American Petroleum Institute. "Electrical Installations in Petroleum Processing Plants." API RP 540, 4th Edition, 2012.

- European Committee for Standardization. "Equipment and Protective Systems for Use in Potentially Explosive Atmospheres." EN 1127-1:2019.

- Mine Safety and Health Administration. "Electric Motor-Driven Mine Equipment and Accessories." 30 CFR Part 18, Code of Federal Regulations.

- International Organization for Standardization. "Rotating Electrical Machines - Part 14: Mechanical Vibration of Certain Machines with Shaft Heights 56 mm and Higher." ISO 21940-14:2012.