YKK motors excel in high voltage environments where reliable power transmission and exceptional durability become essential. These specialized motors find applications across power generation facilities, heavy industrial manufacturing, renewable energy systems, and large-scale commercial operations. Understanding the specific environments where YKK motor technology thrives helps engineers select optimal solutions for demanding electrical applications requiring sustained performance under elevated voltage conditions.

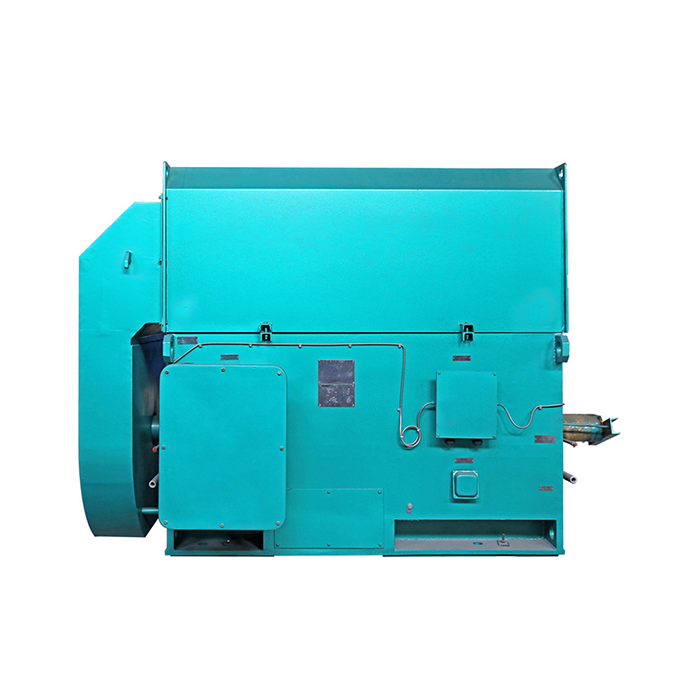

Series:YKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High Voltage Motor Applications in Modern Industries

High voltage environments present unique challenges that demand robust motor solutions. Electric motors operating in these conditions must withstand increased electrical stress while maintaining consistent performance. The relationship between voltage and motor functionality becomes critical when selecting equipment for industrial applications.

Voltage directly impacts motor torque, with torque rising proportionally to the square of voltage. When voltage reaches 110% of rated capacity, torque increases to 121%, creating additional mechanical stresses. This relationship explains why proper voltage management remains crucial for motor longevity and operational efficiency.

Excessive voltage beyond typical operating parameters disrupts the magnetic components within motors. The motor attempts to remagnetize itself by drawing additional current, leading to overheating and potential equipment failure. These factors make selecting appropriate motor technology essential for high voltage applications.

Power Generation Facilities and Electrical Distribution Systems

Power generation plants represent prime environments for YKK motors in high voltage applications. These facilities require motors capable of operating continuously under demanding electrical conditions while maintaining reliability and efficiency.

Turbine generators in thermal power plants utilize high voltage motors for auxiliary systems including cooling water pumps, fuel handling equipment, and ash removal systems. The motors must withstand voltage fluctuations while providing consistent power to critical plant operations.

Hydroelectric facilities employ these motors for gate operations, water intake systems, and generator cooling applications. The combination of high voltage requirements and harsh environmental conditions makes motor selection particularly important in these installations.

Wind farms increasingly rely on high voltage motor technology for pitch control systems, yaw drives, and transformer cooling applications. The remote locations and challenging weather conditions demand motors with exceptional reliability and minimal maintenance requirements.

Heavy Manufacturing and Industrial Automation Systems

Manufacturing environments present diverse applications for high voltage motor technology. Steel mills, aluminum smelters, and chemical processing plants require YKK motors capable of handling extreme electrical and environmental conditions.

Rolling mills in steel production utilize high voltage motors for main drive systems, handling massive mechanical loads while operating under precise speed control. These applications demand motors with superior torque characteristics and thermal management capabilities.

Chemical processing facilities employ high voltage motors for large compressors, pumps, and mixing equipment. The corrosive atmospheres and continuous operation requirements make motor durability and reliability paramount considerations.

Automotive manufacturing plants integrate high voltage motors into robotic systems, conveyor drives, and press operations. The precision requirements and high-speed operations demand motors with excellent dynamic response and positional accuracy.

Aerospace manufacturing facilities utilize these motors for specialized equipment including autoclaves, machining centers, and material handling systems. The quality standards and precision requirements make motor performance consistency critical.

Mining Operations and Extractive Industries

Mining environments present some of the most challenging conditions for electrical equipment. High voltage motors must operate reliably in dusty, humid, and often explosive atmospheres while providing the power needed for heavy-duty operations.

Underground mining operations employ high voltage motors for ventilation fans, water pumps, and material handling systems. These motors must meet strict safety standards while operating in confined spaces with limited access for maintenance.

Surface mining operations utilize large-scale motors for conveyor systems, crushers, and processing equipment. The equipment operates continuously in harsh outdoor conditions, requiring motors with superior environmental protection and thermal management.

Ore processing facilities depend on high voltage motors for ball mills, flotation systems, and concentrate handling equipment. The abrasive materials and continuous operation cycles demand motors with exceptional bearing systems and robust construction.

Commercial HVAC and Building Management Systems

Large commercial buildings and industrial complexes require high voltage motors for HVAC systems serving extensive floor areas. These applications prioritize energy efficiency alongside reliable operation.

Chillers in major office complexes utilize high voltage motors for compressor drives, requiring precise speed control and high efficiency operation. The motors must operate quietly while maintaining consistent performance across varying load conditions.

Industrial refrigeration systems employ high voltage motors for ammonia compressors and glycol circulation pumps. These applications demand motors with specialized sealing and materials compatible with refrigerant environments.

Data centers rely on high voltage motors for cooling systems that maintain critical temperature and humidity conditions. The 24/7 operation requirements and backup power considerations make motor reliability essential.

Water Treatment and Municipal Infrastructure

Water treatment facilities represent another significant application area for high voltage motors. These installations require reliable equipment capable of continuous operation while meeting strict environmental regulations.

Wastewater treatment plants utilize high voltage motors for aeration blowers, sludge pumps, and clarifier drives. The corrosive environment and regulatory requirements demand motors with appropriate materials and protection ratings.

Desalination facilities employ high voltage motors for high-pressure pumps in reverse osmosis systems. These applications require motors capable of maintaining consistent pressure while operating efficiently under varying load conditions.

Municipal water distribution systems use high voltage motors for booster pumps and transmission mains. The critical nature of water supply makes motor reliability and quick maintenance access essential considerations.

Transportation Infrastructure and Transit Systems

Transportation systems increasingly rely on high voltage motor technology for various applications ranging from rail systems to airport facilities. These environments demand reliability and minimal maintenance requirements.

Rail systems employ high voltage motors for traction applications, station ventilation, and escalator drives. The safety requirements and passenger considerations make motor performance consistency critical.

Airport facilities utilize high voltage motors for baggage handling systems, jet bridges, and terminal HVAC equipment. The operational schedules and passenger safety requirements demand motors with exceptional reliability.

Marine facilities employ high voltage motors for dock cranes, cargo handling equipment, and port infrastructure. The saltwater environment and heavy-duty operations require motors with superior corrosion resistance and mechanical strength.

Key Benefits of Proper High Voltage Motor Selection

Choosing appropriate motors for high voltage environments delivers significant operational advantages. Proper selection reduces energy consumption, minimizes maintenance requirements, and extends equipment life cycles.

Energy efficiency improvements can reduce operating costs substantially over motor lifespan. High-quality motors maintain efficiency ratings even under varying load conditions, contributing to overall system performance.

Reliability benefits include reduced downtime, lower maintenance costs, and improved production consistency. These factors become particularly important in critical applications where equipment failure creates significant operational disruptions.

Safety considerations include proper insulation systems, appropriate protection ratings, and compliance with relevant electrical codes. These features protect both equipment and personnel while ensuring regulatory compliance.

Conclusion

YKK motors prove invaluable across diverse high voltage environments, from power generation facilities to manufacturing operations. Understanding application requirements and environmental conditions enables optimal motor selection for reliable, efficient operation. The benefits of proper selection include improved energy efficiency, reduced maintenance costs, and enhanced operational reliability. Whether your application involves industrial automation, infrastructure systems, or specialized manufacturing processes, selecting appropriate motor technology remains critical for long-term success. Professional guidance ensures optimal results while meeting safety and performance requirements.

Frequently Asked Questions

Q1: What voltage levels are considered high voltage for motor applications?

A: High voltage motor applications typically involve systems operating above 1000V AC. Industrial applications commonly use 2.3kV, 4.16kV, 6.6kV, and 13.8kV systems, while utility applications may require even higher voltages.

Q2: How does high voltage affect motor performance and efficiency?

A: High voltage operation allows motors to deliver more power with lower current draw, reducing conductor losses and improving overall system efficiency. However, voltage levels must remain within motor design parameters to prevent damage.

Q3: What special considerations apply to high voltage motor installation?

A: High voltage motor installations require specialized electrical safety procedures, appropriate insulation coordination, proper grounding systems, and compliance with electrical codes. Professional installation and commissioning are essential.

Q4: How often should high voltage motors undergo maintenance?

A: Maintenance schedules depend on operating conditions and manufacturer recommendations. Typical schedules include monthly visual inspections, quarterly electrical testing, and annual comprehensive maintenance including bearing lubrication and insulation testing.

Q5: What protection systems are required for high voltage motors?

A: High voltage motors require comprehensive protection including overcurrent protection, ground fault protection, phase imbalance detection, and thermal monitoring. Advanced systems may include vibration monitoring and partial discharge testing.

Ready to Find Your Perfect YKK Motor Solution? Contact XCMOTOR Today

Selecting the right YKK motor for high voltage environments requires expertise and understanding of your specific application requirements. XCMOTOR specializes in providing comprehensive motor solutions tailored to demanding industrial applications across global markets.

Our extensive experience with high voltage motor applications enables us to recommend optimal solutions for your specific requirements. Whether you need motors for power generation, manufacturing automation, or infrastructure applications, we provide the technical expertise and product quality you demand.

As a trusted YKK motor supplier, we maintain relationships with leading manufacturers while offering competitive pricing and reliable delivery schedules. Our technical team understands the complexities of high voltage applications and can guide you through the selection process.

XCMOTOR offers original products from trusted brands, ensuring you receive authentic components with full manufacturer warranties. Our fast delivery service and dedicated support team, available even on weekends, demonstrate our commitment to customer satisfaction.

Don't let motor selection challenges delay your project timeline. Contact our experienced team to discuss your high voltage motor requirements and discover how we can support your success. Reach out to us today and contact us at xcmotors@163.com for personalized assistance with your motor selection needs.

References

1. IEEE Standard 841-2021: Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors

2. NEMA MG 1-2016: Motors and Generators Standards Publication

3. IEC 60034-1:2017: Rotating Electrical Machines - Part 1: Rating and Performance

4. Chapman, Stephen J. "Electric Machinery Fundamentals," 5th Edition, McGraw-Hill Education, 2012

5. Sen, P.C. "Principles of Electric Machines and Power Electronics," 3rd Edition, John Wiley & Sons, 2013

6. Hughes, Austin and Bill Drury. "Electric Motors and Drives: Fundamentals, Types and Applications," 4th Edition, Newnes, 2013