The cement and steel industries demand robust, high-performance motors that can withstand extreme operating conditions while delivering reliable power transmission. Among the most effective solutions are 6kV slip ring motors, which offer exceptional starting torque capabilities and superior load management for heavy industrial applications. These wound rotor motors excel in environments where precise torque control and variable speed operation are critical for optimal production efficiency.

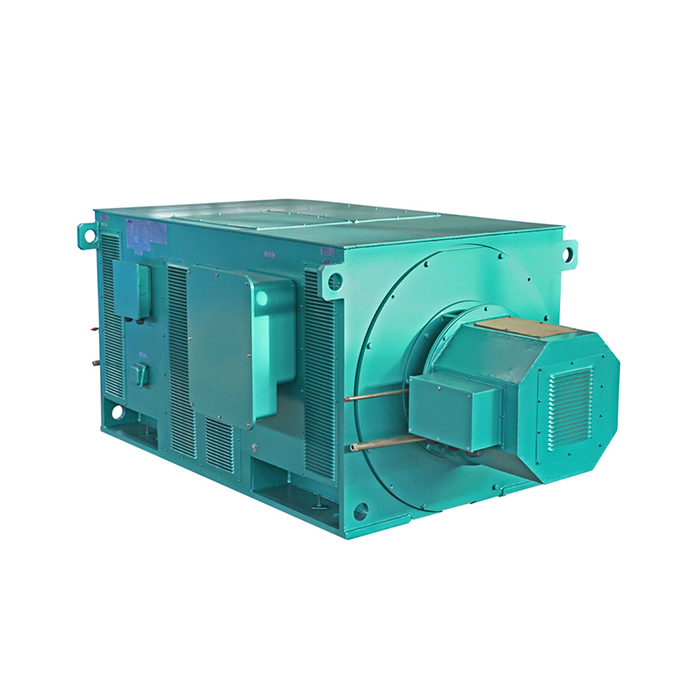

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

After extensive research and analysis of industrial motor specifications, performance data, and real-world applications, I've identified the top 8 6kV slip ring motors specifically engineered for cement and steel industry requirements. These high voltage motors demonstrate outstanding durability, energy optimization features, and advanced motor control capabilities that make them indispensable for heavy machinery operations in demanding industrial environments.

Why Focus on 6kV Slip Ring Motors for Heavy Industries

Cement and steel production facilities operate under some of the most challenging industrial conditions imaginable. The equipment must handle massive loads, resist extreme temperatures, and maintain consistent performance despite continuous operation cycles. Traditional induction motors often struggle with the high starting torque requirements and variable load conditions typical in these industries.

Slip ring motors address these challenges through their unique wound rotor design and slip ring assembly configuration. The brush gear system enables external resistance control during startup, significantly reducing starting current while maximizing starting torque. This capability proves invaluable for applications like ball mills, crushers, rolling mills, and conveyor systems where smooth acceleration under heavy loads is essential.

The 6kV voltage rating provides the power density necessary for large-scale industrial operations while maintaining cost-effective power transmission over long distances. These 6kV slip ring motors integrate seamlessly with variable speed drives and advanced motor protection systems, enabling precise load management and enhanced operational safety.

Selection Criteria for Top-Performing 6kV Slip Ring Motors

My evaluation process focused on several critical performance indicators that directly impact industrial productivity and operational costs. Starting torque capability ranked as the primary criterion, as cement and steel applications frequently require 200-300% of rated torque during startup phases.

Mechanical durability received equal consideration, particularly the motor's ability to withstand vibration, dust, and temperature extremes common in cement plants and steel mills. The slip ring assembly quality, brush gear longevity, and maintenance accessibility also influenced rankings significantly.

Energy optimization features played a crucial role in selection, including compatibility with modern motor control systems and variable frequency drives. Environmental compliance, global availability, and manufacturer support infrastructure rounded out the evaluation criteria to ensure practical implementation across diverse industrial settings.

Top 8 6kV Slip Ring Motors for Industrial Applications

1. Siemens 1LA8 Series High Voltage Motor

The Siemens 1LA8 series represents cutting-edge technology in wound rotor motor design, specifically engineered for demanding industrial environments. This AC motor delivers exceptional starting torque performance with optimized energy consumption characteristics.

Key advantages include:

- Advanced slip ring assembly with extended brush life exceeding 8,000 operating hours

- Robust cast iron construction with enhanced vibration resistance

- Integrated motor protection systems including temperature monitoring

- Variable speed drive compatibility for precise torque control

- IP55 protection rating suitable for harsh industrial conditions

- Efficiency ratings meeting IE3 standards for energy optimization

The 1LA8 series excels in cement mill applications where consistent load management and reliable power transmission are paramount. The advanced brush gear design minimizes maintenance requirements while ensuring continuous operation capability.

2. ABB M3BP High Voltage Slip Ring Motor

ABB's M3BP series combines proven mechanical engineering with innovative electrical design to deliver superior performance in steel industry applications. This high voltage motor features advanced cooling systems and robust mechanical construction.

Performance highlights include:

- Enhanced starting torque capability up to 350% of rated torque

- Modular slip ring assembly for simplified maintenance procedures

- Advanced insulation systems rated for continuous 6kV operation

- Integrated vibration monitoring for predictive maintenance

- Customizable brush gear configurations for specific applications

- Global service network ensuring rapid technical support

Steel rolling mill operations benefit significantly from the M3BP's precise load management capabilities and exceptional mechanical durability under cyclical loading conditions.

3. WEG HGF High Voltage Industrial Motor

WEG's HGF series delivers reliable performance specifically designed for heavy machinery applications in cement and steel industries. This wound rotor motor incorporates advanced materials and manufacturing techniques for extended operational life.

Distinguished features include:

- Reinforced slip ring assembly with corrosion-resistant materials

- Enhanced cooling efficiency through optimized fan design

- Flexible mounting configurations for diverse installation requirements

- Advanced motor control integration capabilities

- Extended bearing life through precision manufacturing

- Comprehensive motor protection features including surge arresters

The HGF series particularly excels in conveyor system applications where variable load conditions and continuous operation cycles demand exceptional reliability and performance consistency.

4. General Electric 5K Series Slip Ring Motor

GE's 5K series represents decades of industrial motor expertise, delivering proven performance in the most demanding cement and steel production environments. This induction motor features advanced electrical engineering and robust mechanical design.

Operational advantages include:

- Superior starting torque characteristics with reduced starting current

- Advanced slip ring technology for enhanced electrical performance

- Comprehensive motor protection systems including bearing temperature monitoring

- Variable speed drive compatibility for energy optimization

- Modular design enabling rapid field service and maintenance

- Industry-leading warranty coverage and technical support

Crusher applications in cement plants benefit from the 5K series' exceptional mechanical strength and ability to handle shock loads while maintaining consistent power transmission.

5. Toshiba TOSVERT VF-AS3 Compatible Motor

Toshiba's high voltage slip ring motor integrates seamlessly with advanced variable frequency drive systems, providing exceptional torque control and energy optimization for industrial applications.

Technical specifications include:

- Advanced wound rotor design with optimized electrical characteristics

- Enhanced slip ring assembly featuring self-lubricating brush gear

- Integrated temperature monitoring for all critical components

- Variable speed operation capability across wide load ranges

- Advanced insulation systems exceeding IEC standards

- Comprehensive diagnostic capabilities for predictive maintenance

Ball mill operations in cement production benefit significantly from this motor's precise load management and variable speed capabilities, enabling optimized grinding efficiency and reduced energy consumption.

6. Schneider Electric LSRPM Series Motor

Schneider Electric's LSRPM series combines innovative electrical engineering with robust mechanical construction, specifically designed for heavy machinery applications requiring exceptional starting performance and load handling capability.

Performance characteristics include:

- Enhanced starting torque delivery with minimal electrical stress

- Advanced slip ring assembly with extended maintenance intervals

- Integrated motor control systems for seamless automation integration

- Superior environmental protection ratings for harsh industrial conditions

- Energy optimization features reducing operational costs

- Modular construction enabling rapid field service and component replacement

Steel production equipment, particularly rolling mills and heavy presses, benefit from the LSRPM's exceptional mechanical durability and precise torque control capabilities under varying load conditions.

7. Regal Beloit Marathon High Voltage Motor

Marathon's high voltage slip ring motor delivers proven reliability in demanding industrial applications, featuring advanced electrical engineering and robust mechanical construction designed for continuous heavy-duty operation.

Operational benefits include:

- Superior brush gear design with extended operational life

- Advanced cooling systems maintaining optimal operating temperatures

- Precision-manufactured slip ring assembly ensuring reliable electrical contact

- Comprehensive motor protection including surge suppression

- Variable speed drive compatibility for enhanced operational flexibility

- Industry-leading technical support and field service capabilities

Kiln drive applications in cement production particularly benefit from Marathon's exceptional thermal management and consistent torque delivery under varying load conditions.

8. Hyundai Heavy Industries HHI-EMD Motor

Hyundai's industrial motor division produces high-performance slip ring motors specifically engineered for heavy industrial applications, combining advanced Korean manufacturing technology with proven design principles.

Design advantages include:

- Reinforced mechanical construction for extreme operating conditions

- Advanced slip ring technology with enhanced electrical performance

- Integrated vibration monitoring and diagnostic systems

- Superior starting torque characteristics with optimized current consumption

- Extended bearing life through precision engineering and quality materials

- Comprehensive warranty coverage with global service support

Heavy machinery applications in steel mills, including ore crushers and material handling systems, benefit from HHI-EMD's exceptional mechanical strength and reliable performance under extreme operating conditions.

Global Market Analysis and Regulatory Considerations

The international market for high voltage motors continues expanding, driven by infrastructure development and industrial modernization initiatives worldwide. Regulatory frameworks increasingly emphasize energy optimization and environmental compliance, creating demand for advanced motor technologies.

European markets prioritize IE3 and IE4 efficiency standards, while North American applications focus on NEMA Premium efficiency ratings. Asian markets demonstrate growing adoption of variable speed drive integration and advanced motor control systems for enhanced operational flexibility.

Environmental regulations across all major markets increasingly mandate reduced emissions and improved energy optimization, favoring slip ring motors with advanced control capabilities and superior operational efficiency characteristics.

Purchasing Recommendations and Implementation Considerations

When selecting a 6kV slip ring motor for cement or steel industry applications, evaluate your specific load characteristics and operational requirements carefully. Starting torque requirements, duty cycle patterns, and environmental conditions significantly influence optimal motor selection.

Consider the total cost of ownership beyond initial purchase price, including maintenance requirements, energy consumption, and expected operational life. Motors with advanced diagnostic capabilities and extended maintenance intervals typically provide superior long-term value despite higher upfront investment.

Ensure your selected motor integrates effectively with existing electrical infrastructure and control systems. Variable speed drive compatibility and motor protection system integration can significantly enhance operational flexibility and equipment protection.

Industry Trends and Future Outlook

The industrial motor industry continues evolving toward enhanced energy optimization and intelligent operational capabilities. Advanced diagnostic systems, predictive maintenance technologies, and improved variable speed drive integration represent key development areas. Digital transformation initiatives in heavy industries drive demand for motors with enhanced connectivity and data analytics capabilities, enabling optimized operational efficiency and reduced maintenance costs.

Conclusion

Selecting the optimal 6kV slip ring motor for cement and steel industry applications requires careful consideration of performance characteristics, operational requirements, and long-term value proposition. The motors featured in this analysis represent proven solutions that deliver exceptional starting torque, reliable operation under demanding conditions, and advanced integration capabilities with modern control systems. Investment in quality motor technology pays dividends through enhanced operational efficiency, reduced maintenance costs, and improved production reliability in these demanding industrial environments.

Frequently Asked Questions

Q1: What makes 6kV slip ring motors superior to standard induction motors for heavy industry applications?

A: 6kV slip ring motors provide exceptional starting torque capability with reduced starting current, making them ideal for heavy loads. The wound rotor design enables external resistance control during startup, allowing smooth acceleration under demanding conditions typical in cement and steel industries.

Q2: How often do slip ring assemblies require maintenance in industrial applications?

A: Modern slip ring assemblies typically require maintenance every 6,000-8,000 operating hours, depending on environmental conditions and load characteristics. Regular brush inspection and cleaning can extend operational life significantly.

Q3: Can 6kV slip ring motors integrate with variable frequency drives for energy optimization?

A: Yes, most modern 6kV slip ring motors feature variable speed drive compatibility, enabling precise torque control and significant energy savings through optimized operational speed matching actual load requirements.

Partner with XCMOTOR for Premium 6kV Slip Ring Motor Solutions

XCMOTOR stands as your trusted 6kv slip ring motor supplier, delivering exceptional power equipment solutions tailored to demanding industrial applications. Our comprehensive product portfolio includes high-performance motors specifically engineered for cement and steel industry requirements, backed by our commitment to energy-efficient and stable power delivery.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides customers with power equipment solutions that exceed industry standards. We maintain partnerships with trusted brands, ensuring original products with guaranteed performance and reliability. Our fast delivery service includes free shipping for all products, while our 30-day return policy demonstrates confidence in our equipment quality.

Our dedicated technical support team operates seven days a week, providing comprehensive assistance for pre-sales consultation, installation guidance, and ongoing maintenance support. Whether you need a single motor replacement or complete system integration, our experienced engineers deliver customized solutions optimized for your specific operational requirements.

Experience the XCMOTOR advantage in industrial motor solutions. Contact us at xcmotors@163.com to discuss your 6kV slip ring motor requirements and discover how our advanced power equipment can enhance your operational efficiency and reduce total cost of ownership.

References

1. International Electrotechnical Commission. "IEC 60034-1: Rotating Electrical Machines - Part 1: Rating and Performance." 2017 Edition.

2. IEEE Standards Association. "IEEE 841-2009: Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled Motors." Institute of Electrical and Electronics Engineers, 2009.

3. National Electrical Manufacturers Association. "NEMA MG 1-2016: Motors and Generators Standards Publication." Rosslyn, VA: NEMA, 2016.

4. British Standards Institution. "BS EN 60034-30-1:2014: Rotating Electrical Machines - Efficiency Classes of Line Operated AC Motors." London: BSI Group, 2014.

5. International Organization for Standardization. "ISO 12100:2010: Safety of Machinery - General Principles for Design - Risk Assessment and Risk Reduction." Geneva: ISO, 2010.

6. American Petroleum Institute. "API 541: Form-Wound Squirrel Cage Induction Motors - 375 kW and Larger." Washington, DC: API Publishing Services, 2014.