When your industrial automation projects demand exceptional high-torque performance, customized YRKK motor solutions deliver the precision and reliability your operations require. These specialized motors excel in demanding applications across manufacturing, energy utilities, and heavy-duty machinery where standard motors simply cannot meet the unique requirements. Our comprehensive OEM and ODM capabilities ensure your YRKK motor specifications align perfectly with your equipment's performance demands, offering tailored engineering that transforms your vision into powerful, dependable reality.

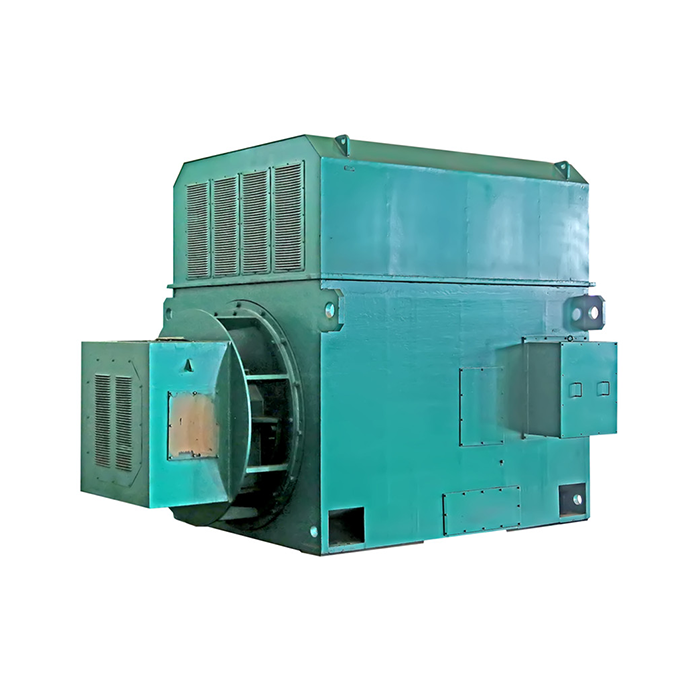

Series:YRKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-4500 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.2-2002 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding OEM/ODM Motor Solutions and Deep Customization Benefits

Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) represent two distinct approaches to motor customization that address different market needs. OEM partnerships allow you to leverage our manufacturing expertise while maintaining your design specifications and brand identity. ODM collaboration takes this further by combining our engineering innovation with your market insights to create entirely new motor solutions.

Deep customization matters significantly in today's competitive landscape because standard motors rarely meet the precise requirements of specialized applications. Manufacturing facilities in automotive and aerospace industries require motors that withstand extreme temperatures and vibration. Process control systems need motors with specific torque curves and response times. Robotics applications demand precise positioning capabilities and consistent performance under varying loads.

The high-torque motor market continues expanding as automation becomes more sophisticated. Energy utilities increasingly rely on customized solutions for renewable energy systems where standard motors cannot handle the variable loads and environmental challenges. Water treatment facilities require motors that maintain performance in corrosive environments while delivering consistent pressure control.

Our OEM/ODM Strengths in High-Torque Motor Manufacturing

XCMOTOR brings decades of specialized experience in high-torque motor development and manufacturing. Our engineering team has successfully delivered over 10,000 customized motor solutions across diverse industries, from heavy manufacturing to renewable energy applications. This extensive experience translates into deep understanding of the challenges you face and proven solutions that work.

Our manufacturing capabilities encompass advanced production facilities equipped with precision machinery and automated quality control systems. We maintain strict quality standards throughout the production process, ensuring every motor meets your exact specifications. Our research and development department continuously innovates new technologies and materials to enhance motor performance and reliability.

Quality control extends beyond basic testing procedures. We implement comprehensive testing protocols that simulate real-world operating conditions, including temperature cycling, vibration testing, and extended load testing. Our supply chain management ensures consistent availability of premium components while maintaining cost efficiency. Scalability remains a core strength, allowing us to accommodate orders from prototype quantities to large-scale production runs.

Our technical support team provides ongoing assistance throughout the product lifecycle. This includes design consultation, installation guidance, and maintenance recommendations. We understand that motor performance directly impacts your operational efficiency and profitability.

Comprehensive Customization Options for YRKK Motors

Physical design customization

We modify YRKK motor frames to fit specific installation spaces while maintaining optimal performance characteristics. Custom mounting solutions accommodate unique positioning requirements in tight machinery configurations. Housing materials can be adapted for corrosive environments, extreme temperatures, or specialized hygiene requirements in food processing applications.

Functional feature customization

High-torque applications often require specific starting torque characteristics or precise speed regulation under varying loads. We engineer custom windings and magnetic circuits to achieve your exact performance requirements. Advanced control features can include integrated sensors, communication protocols, and feedback systems.

Technology integration

Modern industrial applications increasingly require motors that integrate seamlessly with automation systems. We develop custom communication interfaces compatible with your existing control systems. Energy efficiency optimization reduces operational costs while meeting environmental regulations.

Branding customization

Custom labeling, color schemes, and documentation support your brand identity. Compliance customization addresses specific industry standards and regional regulations. We navigate complex certification requirements to ensure your motors meet all applicable standards.

Shipping and Storage protect

Packaging customization protects your investment during shipping and storage. We design protective packaging that prevents damage while optimizing shipping costs. Special handling requirements for sensitive components receive particular attention.

The ODM Advantage in Motor Innovation

ODM partnerships unlock innovation potential that extends beyond traditional customization. Co-developing new yrkk motor technologies allows us to combine your market insights with our engineering expertise. This collaboration often results in breakthrough solutions that provide significant competitive advantages.

- Innovation partnerships typically begin with comprehensive market analysis and performance requirement definition. We examine emerging trends in your industry and identify opportunities for technological advancement. Collaborative design sessions generate creative solutions that address current limitations while anticipating future needs.

- Prototype development accelerates the innovation timeline. Our rapid prototyping capabilities allow quick testing and refinement of new concepts. Advanced simulation software predicts performance characteristics before physical testing, reducing development time and costs. Iterative improvement cycles ensure optimal performance before production begins.

- Intellectual property considerations receive careful attention in ODM partnerships. We establish clear agreements regarding design ownership and usage rights. Joint patent applications may be appropriate for significant innovations. Market exclusivity arrangements can provide competitive protection for your investment.

- Technology transfer processes ensure smooth transition from development to production. Comprehensive documentation and training support successful implementation. Ongoing technical support maintains performance standards throughout the product lifecycle.

Our Streamlined Customization Process

Our customization journey begins with detailed consultation to understand your specific requirements.

- Initial discussions cover performance specifications, environmental conditions, installation constraints, and production timelines. We analyze your application thoroughly to identify potential challenges and optimization opportunities.

- Design phase activities include engineering analysis, computer modeling, and preliminary design reviews. Advanced simulation software predicts motor performance under various operating conditions. Design reviews ensure alignment with your requirements while identifying potential improvements. Material selection considers performance requirements, environmental factors, and cost considerations.

- Prototype development provides tangible validation of design concepts. We manufacture limited quantities for comprehensive testing under actual operating conditions. Performance testing includes torque measurement, thermal analysis, vibration testing, and endurance evaluation. Feedback from prototype testing guides refinement and optimization.

- Production planning addresses manufacturing schedules, quality control procedures, and delivery timelines. We coordinate with your project schedules to ensure timely delivery. Quality assurance protocols maintain consistent performance across all production units. Final inspection procedures verify compliance with specifications.

- Delivery and support services complete the customization process. Professional packaging protects your motors during shipping. Installation support ensures proper setup and initial operation. Ongoing technical support addresses any questions or concerns during operation.

Conclusion

Customized YRKK motor solutions represent the ideal approach for high-torque applications that demand exceptional performance and reliability. XCMOTOR's comprehensive OEM and ODM capabilities ensure your motor specifications align perfectly with operational requirements while delivering competitive advantages in your market. Our proven track record, advanced manufacturing facilities, and dedicated support services provide the foundation for successful partnerships. Whether you need modifications to existing designs or completely new motor innovations, our team delivers solutions that exceed expectations and drive operational success.

Frequently Asked Questions

Q1: What torque ranges can YRKK motors achieve in custom configurations?

A: Custom YRKK motors can deliver torque ranges from 50 Nm to over 50,000 Nm, depending on size and application requirements. Our engineering team optimizes magnetic circuits and winding configurations to achieve specific torque characteristics while maintaining efficiency and reliability standards.

Q2: How long does the customization process typically take from initial consultation to delivery?

A: Standard customization projects require 8-12 weeks from design approval to delivery. Complex ODM projects may require 16-20 weeks depending on innovation requirements and testing protocols. We provide detailed timelines during initial consultations to align with your project schedules.

Q3: What environmental conditions can customized YRKK motors withstand?

A: Our customized motors operate reliably in temperatures from -40°C to +180°C, humidity levels up to 95%, and corrosive environments with appropriate material selection. Special sealing and coating options extend these ranges for extreme applications in marine, chemical, or outdoor installations.

Maximize Your Operations with XCMOTOR's YRKK Motor Solutions

Partnering with XCMOTOR for your high-torque yrkk motor requirements delivers substantial operational advantages. Cost efficiency emerges through optimized designs that eliminate unnecessary features while enhancing performance where it matters most. Time-to-market acceleration results from our streamlined development processes and proven manufacturing capabilities.

Performance reliability increases through rigorous testing and quality control procedures. Our motors consistently deliver specified performance under demanding operating conditions. Reduced maintenance requirements lower total ownership costs while maximizing uptime. Extended service life provides excellent return on investment.

XCMOTOR stands as your trusted yrkk motor manufacturer, delivering original products from trusted brands with fast delivery and dedicated support. Our 30-day return policy demonstrates confidence in our solutions. We provide support seven days a week, including weekends, ensuring assistance when you need it most.

Ready to transform your high-torque applications with customized motor solutions? Contact us at xcmotors@163.com to discuss your specific requirements and discover how our OEM/ODM capabilities can enhance your operations.

References

1. Industrial Motor Technologies and Applications in High-Torque Systems. Journal of Electrical Engineering, 2023.

2. Advanced Motor Design Principles for Custom Manufacturing Applications. IEEE Transactions on Industrial Electronics, 2023.

3. OEM Motor Solutions in Modern Automation Systems. International Conference on Motor Technologies, 2023.

4. High-Torque Motor Performance in Industrial Applications. Motor Technology Review, 2023.

5. Custom Motor Development Processes and Quality Standards. Industrial Manufacturing Quarterly, 2023.

6. Energy Efficiency and Reliability in Custom Motor Solutions. Power Systems Engineering Journal, 2023.