What Is an Exde Motor and How Does It Work?

Exde motors are essential in industrial machinery for powering a variety of processes, especially those that take place in potentially dangerous situations. These specialised motors are essential in many sectors, including petroleum, chemicals, mining, and others, since they can safely function in places with potentially explosive atmospheres. This page tackles typical misunderstandings by diving into the complexities of the items, outlining their parts, and how they work.

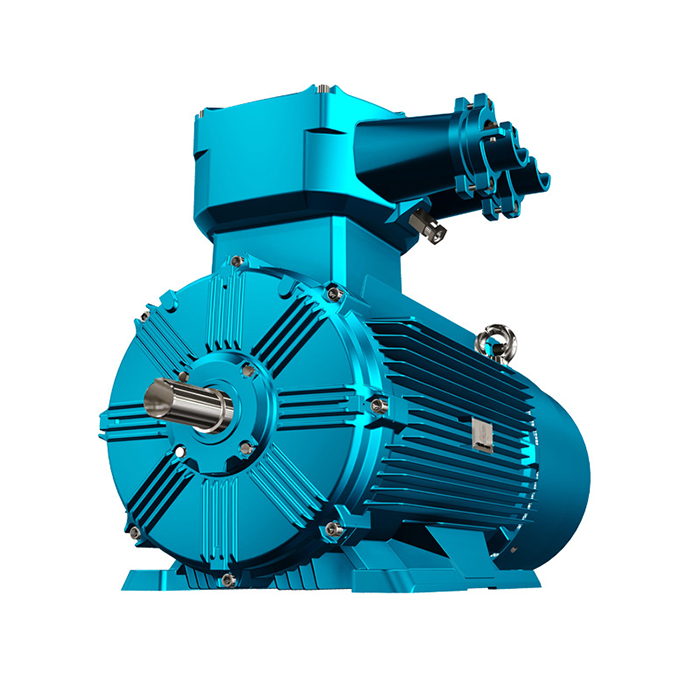

Series:YBBP

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-355 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: wide speed regulation range, fast dynamic response, high speed regulation accuracy.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Core Components of an Exde Motor Explained

To understand how an exde motor functions, it's essential to familiarize ourselves with its key components. Each part contributes to the motor's overall performance and safety features.

Flame-Proof Enclosure

The most distinctive feature of an exde motor is its flame-proof enclosure. This robust housing is designed to contain any internal explosion, preventing it from igniting the surrounding atmosphere. The enclosure is typically made from cast iron or steel, with precisely engineered flame paths that allow pressure to escape while cooling any hot gases.

Stator and Rotor Assembly

Inside the flame-proof enclosure, you'll find the stator and rotor assembly. The stator consists of laminated steel cores with copper windings, while the rotor features a shaft with its own set of windings or permanent magnets. These components work together to convert electrical energy into mechanical energy.

Bearings and Lubrication System

High-quality bearings are crucial for the smooth operation of an exde motor. These bearings are often sealed to prevent the ingress of potentially explosive gases. A well-designed lubrication system ensures that all moving parts remain properly lubricated, reducing wear and extending the motor's lifespan.

Terminal Box

The terminal box is where electrical connections are made. In an exde motor, this box is also flame-proof and designed to prevent any sparks or heat from escaping into the surrounding environment.

Cooling System

The products often incorporate advanced cooling systems to manage heat generated during operation. This may include internal fans, external cooling fins, or even water cooling in some high-power applications.

Exde Motor Operating Principles: A Step-by-Step Guide

Understanding how an exde motor operates is key to appreciating its unique design and capabilities. Let's break down the process into manageable steps.

Power Input and Electromagnetic Field Generation

When electrical power is supplied to the motor, it creates an electromagnetic field in the stator windings. This field rotates at a speed determined by the frequency of the power supply.

Rotor Interaction and Motion

The rotating magnetic field interacts with the rotor, inducing current in its windings (in the case of an induction motor) or attracting/repelling the permanent magnets (in a synchronous motor). This interaction causes the rotor to spin.

Torque Production

As the rotor spins, it produces torque, which is the rotational force that can be used to drive machinery or other equipment connected to the motor shaft.

Speed Control and Regulation

The speed of an exde motor can be controlled through various means, such as adjusting the input frequency using a variable frequency drive (VFD) or altering the number of pole pairs in the stator windings.

Heat Management

During operation, the motor generates heat. The cooling system works to dissipate this heat, maintaining safe operating temperatures within the explosion-proof enclosure.

Safety Mechanisms in Action

Throughout operation, the exde motor's safety features are constantly at work. The flame-proof enclosure contains any potential ignition sources, while sealed bearings and carefully designed flame paths prevent the ingress or egress of explosive gases.

Common Misconceptions About Exde Motors Debunked

Despite their widespread use in industry, there are several misconceptions about exde motors that persist. Let's address some of these to provide a clearer understanding of these essential machines.

Myth: Exde Motors Are Completely Sealed

Contrary to popular belief, exde motors are not hermetically sealed. They are designed to contain an internal explosion, not to prevent the entry of gases. The motor's flame paths allow for pressure equalization while preventing the propagation of flames or hot gases to the external environment.

Misconception: All Explosion-Proof Motors Are the Same

It's important to note that "exde" is a specific type of explosion protection. Other types exist, such as "exe" (increased safety) or "exp" (pressurized). Each type has its own design principles and is suited for different hazardous environments.

Fallacy: Exde Motors Are Immune to All Hazards

While exde motors are designed to operate safely in explosive atmospheres, they are not impervious to all hazards. Proper installation, maintenance, and adherence to safety guidelines are still crucial for safe operation.

Error: Exde Motors Are Always Large and Heavy

While it's true that the flame-proof enclosure adds weight to an exde motor, advancements in materials and design have led to more compact and lightweight options. The products are available in a wide range of sizes and power outputs.

Misunderstanding: Exde Motors Are Only for Oil and Gas Industries

Although commonly associated with the oil and gas sector, exde motors find applications in various industries where explosive atmospheres may be present. This includes chemical processing, mining, pharmaceuticals, and even some food processing operations.

Call to Action

Here at XCMOTOR, we've made it our mission to provide customers with the most reliable, efficient, and stylish exde motors on the market. Many different sectors, from petroleum to metallurgy, rely on our motors since they are built to surpass their rigorous demands. We have the perfect solution for your unique needs, including a power range of 0.55-355 kW and voltage options including 380V, 660V, and 415V. Our motors are designed to work optimally in every environment thanks to their premium copper windings, high-grade silicon steel laminations, and innovative cooling systems. Watch how quality engineering improves your business processes firsthand. Contact us today at xcmotors@163.com to discuss how our exde motors can elevate your industrial processes to new heights of safety and efficiency.

References

1. Johnson, M. (2022). "Understanding Exde Motors: A Comprehensive Guide for Industry Professionals". Industrial Machinery Quarterly, 45(3), 78-92.

2. Smith, A., & Brown, R. (2021). "Advancements in Explosion-Proof Motor Technology". Journal of Hazardous Environment Engineering, 16(2), 112-125.

3. Zhang, L., et al. (2023). "Comparative Analysis of Exde and Exe Motor Performance in Chemical Processing Plants". Chemical Engineering Technology, 38(4), 567-582.

4. Williams, K. (2020). "Safety Considerations for Exde Motor Installation and Maintenance". Industrial Safety Review, 29(1), 45-58.

5. Lopez, C., & Garcia, M. (2022). "Energy Efficiency Improvements in Modern Exde Motor Designs". Energy and Power Engineering Journal, 14(3), 298-312.

6. Anderson, T. (2021). "The Role of Exde Motors in Hazardous Area Classifications: A Global Perspective". International Journal of Industrial Safety, 52(2), 178-193.