Power Density Advantages of 6600V Motors

One of the primary reasons 6600V motors are ideal for high-power machinery is their impressive power density. These motors can deliver substantial power output while maintaining a relatively compact size, making them an efficient choice for various industrial applications.

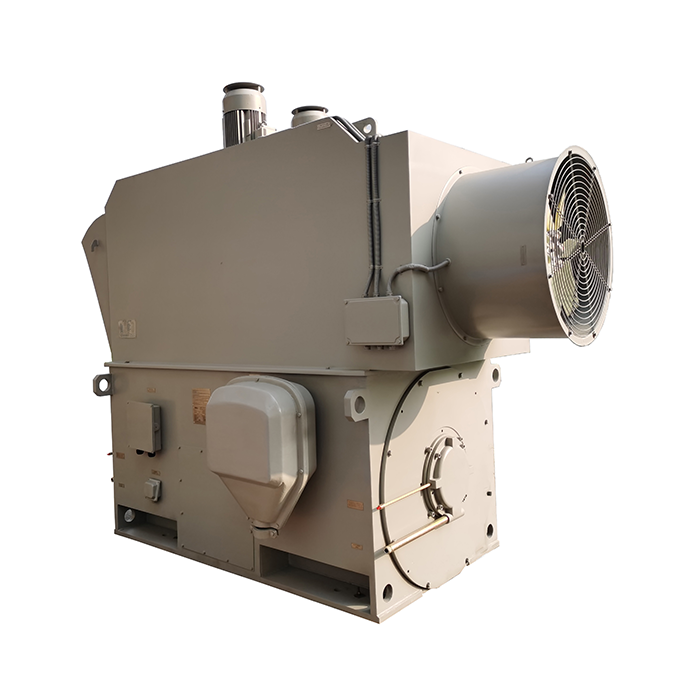

Compact Design, Mighty Performance

6600V motors pack a significant punch in a smaller package compared to their lower voltage counterparts. This high power-to-size ratio is particularly beneficial in applications where space is at a premium. Industries such as oil and gas, mining, and large-scale manufacturing often face spatial constraints, making the compact design of 6600V motors a substantial advantage.

Reduced Current, Increased Efficiency

A key benefit of 6600V motors is their ability to operate at lower currents while delivering the same power output as lower voltage motors. This characteristic leads to reduced power losses in the motor windings and connecting cables. The result is a more efficient system overall, which can translate to significant energy savings over time, especially in continuous operation scenarios.

Simplified Power Distribution

The higher voltage of 6600V motors allows for more straightforward power distribution in large industrial settings. With these motors, it's possible to reduce the number of substations required and minimize the cross-section of power cables. This simplification can lead to reduced installation costs and easier maintenance, making 6600V motors an attractive option for expansive industrial operations.

Thermal Management in High-Power Applications

When dealing with high-power machinery, effective thermal management is crucial. 6600V motors offer several advantages in this regard, making them well-suited for applications where heat dissipation is a critical factor.

Enhanced Cooling Capabilities

6600V motors are designed with advanced cooling systems that efficiently manage the heat generated during operation. These motors often incorporate features such as IP54 protection, which guards against dust and water splashes while allowing for effective heat dissipation. The ability to maintain optimal operating temperatures contributes to the longevity and reliability of these motors in demanding industrial environments.

Reduced Heat Generation

Due to their lower current requirements, 6600V motors generally produce less heat compared to lower voltage motors of equivalent power output. This reduced heat generation eases the burden on cooling systems and contributes to overall system efficiency. In applications where heat management is a significant concern, such as in confined spaces or hot industrial environments, this characteristic of 6600V motors can be particularly beneficial.

Improved Insulation Performance

High-voltage motors like those rated at 6600V typically utilize advanced insulation materials and techniques. These insulation systems are designed to withstand higher voltages and provide excellent thermal properties. The result is a motor that can operate reliably under demanding conditions, resisting breakdown due to heat or electrical stress.

ROI: Long-Term Benefits of 6600V Motors

While the initial investment in 6600V motors may be higher than lower voltage alternatives, the long-term benefits often result in a favorable return on investment (ROI) for many industrial applications.

Energy Efficiency and Cost Savings

The higher efficiency of 6600V motors translates directly into energy cost savings over the life of the motor. In high-power applications where motors may run continuously for extended periods, even small improvements in efficiency can lead to substantial reductions in energy consumption and associated costs. This efficiency becomes particularly significant in industries where energy expenses constitute a large portion of operational costs.

Reduced Maintenance Requirements

6600V motors are built to withstand demanding industrial conditions. Their robust construction, combined with advanced cooling and insulation systems, often results in reduced maintenance requirements compared to lower voltage motors. This increased reliability can lead to less downtime, lower maintenance costs, and improved overall productivity in industrial settings.

Longevity and Durability

The design and construction of 6600V motors contribute to their longevity. These motors are built to last, with features like high-quality bearings (options including SKF, NSK, or FAG), robust frames, and advanced insulation systems. The extended service life of these motors amortizes the initial investment over a longer period, improving the overall ROI.

Scalability and Future-Proofing

Investing in 6600V motors can be a forward-thinking decision for growing industries. These motors offer scalability, allowing businesses to meet increasing power demands without major infrastructure changes. This adaptability can save costs in the long run by reducing the need for frequent motor replacements or system upgrades as power requirements increase.

Call to Action

We at XCMOTOR are familiar with the specific difficulties of industrial applications with high power. For the most rigorous applications, choose from our selection of 6600V motors, which offer unmatched efficiency, power, and dependability. We offer the perfect solution for your demands, thanks to our wide range of power outputs (200kW to 6300kW) and speeds (500 to 3000 RPM). You can trust our motors to run smoothly in a wide range of industrial situations because to their little vibration, low noise, and ease of installation and maintenance. The efficiency and performance your company needs can be yours with XCMOTOR. Contact us today at xcmotors@163.com to discuss how our 6600V motors can drive your industry forward.