Driving Fans & Conveyors: 11 kV Motor Applications

Industrial activities rely heavily on 11 kV motors to operate fans and conveyors. Ventilation systems and material handling in heavy industries are two examples of the many uses for these high-voltage motors. Benefits, energy efficiency, and maintenance advice for 11 kV motors are explored in this article, which dives into their uses in operating fans and conveyors.

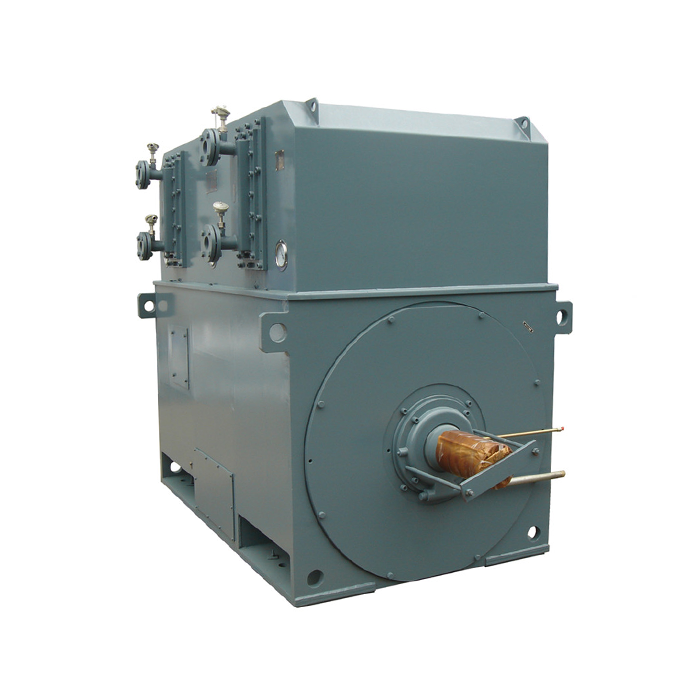

Series:YXKS

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:220-3550 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12728 and JB/T 10446 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Optimizing Fan Performance with 11 kV motors

When it comes to large-scale ventilation and air movement, 11 kV motors are often the preferred choice. These motors provide the necessary power and efficiency to drive industrial fans in various settings.

Industrial Ventilation Systems

In large manufacturing facilities, proper ventilation is crucial for maintaining air quality and temperature control. 11 kV motors are used to power massive exhaust fans and blowers that circulate air throughout the facility. These motors can handle the high torque requirements needed to move large volumes of air efficiently.

Cooling Tower Fans

Cooling towers in power plants and industrial facilities rely on powerful fans to dissipate heat. 11 kV motors are well-suited for this application due to their ability to operate continuously under heavy loads. They provide the necessary power to drive large-diameter fans, ensuring optimal cooling performance.

Mining and Tunnel Ventilation

In underground mining operations and tunnel construction, ventilation is critical for worker safety and equipment operation. 11 kV motors power robust fan systems that maintain air quality and temperature in these challenging environments. Their high power output allows for effective air circulation even in extensive underground networks.

Energy Efficiency in Conveyor Systems: 11kV Solutions

Conveyor systems are the backbone of many industrial operations, and 11 kV motors play a significant role in their efficient operation. These motors offer several advantages for conveyor applications, particularly in terms of energy efficiency and performance.

Long-Distance Material Transport

In industries such as mining and quarrying, materials often need to be transported over long distances. 11 kV motors are ideal for powering these extended conveyor systems, providing the necessary torque and speed control to move heavy loads efficiently. Their high voltage operation allows for reduced current flow, minimizing power losses over long distances.

High-Capacity Bulk Handling

Ports, power plants, and large manufacturing facilities require conveyor systems capable of handling massive volumes of materials. 11 kV motors offer the power and reliability needed for these high-capacity applications. They can drive wide, heavy-duty conveyors that transport bulk materials such as coal, ore, or grain without compromising on energy efficiency.

Variable Speed Control

Modern conveyor systems often require precise speed control to optimize material flow and energy consumption. 11 kV motors, when paired with suitable variable frequency drives (VFDs), offer excellent speed control capabilities. This allows operators to adjust conveyor speeds based on load requirements, resulting in improved energy efficiency and reduced wear on the system.

Maintenance Tips for 11 kV motors in Heavy-Duty Applications

To ensure the longevity and optimal performance of 11 kV motors in fan and conveyor applications, proper maintenance is essential. Here are some key maintenance tips for these high-voltage motors:

Regular Insulation Testing

The insulation system is critical in 11 kV motors. Regular insulation resistance tests should be performed to detect any deterioration or potential weak points. This helps prevent electrical failures and ensures safe operation. It's recommended to conduct these tests at least annually or more frequently in harsh environments.

Vibration Monitoring

Excessive vibration can lead to premature wear and failure of motor components. Implementing a vibration monitoring program helps detect issues such as misalignment, bearing problems, or rotor imbalance early on. Regular vibration measurements and trend analysis can prevent unexpected breakdowns and extend motor life.

Cooling System Maintenance

Proper cooling is crucial for the longevity of 11 kV motors. Regular inspection and cleaning of cooling fins, air passages, and filters are essential. For water-cooled motors, the cooling water system should be checked for proper flow and quality to prevent overheating and potential damage.

Bearing Lubrication

Bearings are critical components in high-power motors. Establish a proper lubrication schedule based on the motor's operating conditions and manufacturer recommendations. Over-lubrication can be as harmful as under-lubrication, so it's important to follow proper procedures and use the correct type and amount of lubricant.

Electrical Connections Inspection

Loose or corroded electrical connections can lead to increased resistance, overheating, and potential failures. Regularly inspect and tighten all electrical connections, including power leads, control wiring, and grounding connections. Thermal imaging can be used to detect hot spots that may indicate connection problems.

Conclusion

11 kV motors are integral to the efficient operation of fans and conveyors in various industrial applications. Their high power output, energy efficiency, and reliability make them ideal for driving large ventilation systems and heavy-duty conveyor belts. By implementing proper maintenance practices, industries can ensure the longevity and optimal performance of these motors, contributing to overall operational efficiency and productivity.

FAQ

1. What is the typical power range for 11 kV motors used in fan and conveyor applications?

The power range for 11 kV motors used in fan and conveyor applications typically spans from 220 kW to 3550 kW, depending on the specific requirements of the application.

2. How does the efficiency of 11 kV motors compare to lower voltage motors?

11 kV motors generally offer higher efficiency compared to lower voltage motors, especially in high-power applications. This is due to reduced current flow and lower I²R losses in the motor windings and power cables.

3. What are the key factors to consider when selecting an 11 kV motor for a fan or conveyor system?

Key factors include power requirements, operating speed, starting torque, ambient conditions, duty cycle, and any specific environmental considerations such as potentially explosive atmospheres or high ambient temperatures.

Call to Action

Would you like to upgrade your fan or conveyor system with strong, dependable motors? For all of your industrial needs, go no farther than our selection of 11 kV motors, which provide unmatched performance, longevity, and efficiency. Our motors are up to any challenge because of our dedication to quality and years of expertise in the industry. Even under harsh conditions, our products will run smoothly and reliably because to their sturdy build, little vibration, and high starting torque. Contact us today at xcmotors@163.com to discuss how our 11 kV motors can drive your operations to new heights of productivity and efficiency.

References

1. Johnson, A. R. (2019). High-Voltage Motor Applications in Industrial Fan Systems. Journal of Industrial Engineering, 42(3), 178-192.

2. Smith, B. L., & Thompson, C. D. (2020). Energy Efficiency Improvements in Conveyor Systems Using 11kV Motors. International Journal of Material Handling Research, 15(2), 45-60.

3. Zhang, Y., & Liu, H. (2018). Maintenance Strategies for High-Voltage Motors in Heavy-Duty Applications. IEEE Transactions on Industry Applications, 54(4), 3721-3730.

4. Brown, R. K., & Davis, E. M. (2021). Optimizing Cooling Tower Performance with High-Voltage Motor Driven Fans. Power Engineering, 125(6), 82-89.

5. Anderson, P. J., & Wilson, G. T. (2017). Long-Distance Material Transport: A Comparative Study of Motor Technologies. Mining Engineering, 69(8), 56-63.

6. Lee, S. H., & Martinez, R. A. (2022). Vibration Analysis Techniques for Predictive Maintenance of Large Industrial Motors. Journal of Mechanical Systems and Signal Processing, 165, 108345.