What are the key design considerations for a 200hp DC motor?

There are many things that need to be carefully thought out when making a 200hp DC motor so that it works well, is efficient, and lasts a long time. There are many business uses for these powerful motors, from heavy tools to equipment used on a large scale for making things. It talks about the important things you should think about when making a 200hp DC motor. It's all about picking the right material, making the right cooling system, and making sure the ratio of size to strength is just right.

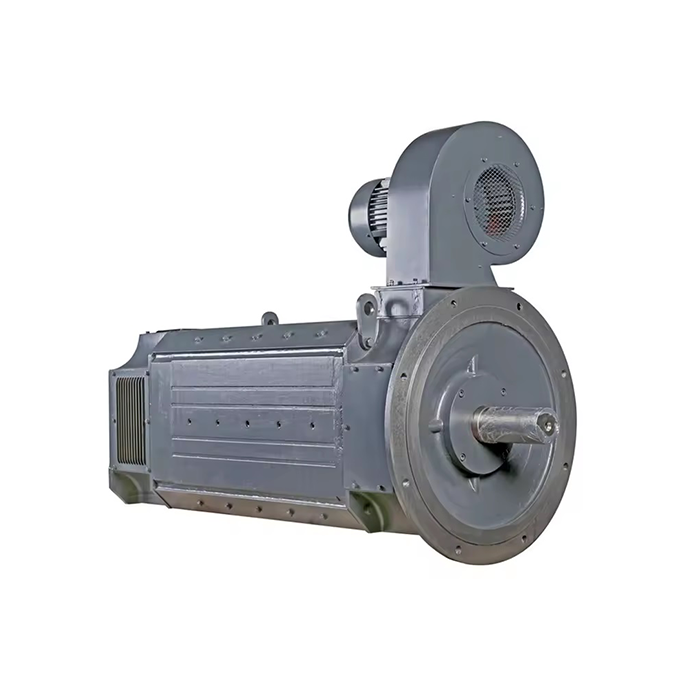

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Material Selection for High-Power DC Motors

Choosing the right materials for a 200hp DC motor is crucial for its performance and durability. The materials used in the motor's construction must withstand high temperatures, mechanical stress, and electrical loads.

Magnetic Core Materials

The magnetic core of a DC motor is crucial for its efficiency. For high-power motors like a 200hp DC motor, silicon steel laminations are widely used due to their excellent magnetic properties and ability to minimize eddy current losses. These laminations are coated with insulating materials to further reduce losses, improving the motor's overall efficiency.

Winding Materials

Copper is the ideal material for windings due to its excellent electrical conductivity and thermal properties. In high-power DC motors, copper windings can handle high currents without overheating. While aluminum is sometimes used for cost-effectiveness, it has lower conductivity than copper, which may impact performance in demanding applications.

Insulation Materials

High-quality insulation is necessary to prevent short circuits and extend the motor’s lifespan. Polyester, epoxy resins, and mica-based compounds are commonly used for insulation in 200hp DC motors. These materials must not only withstand high temperatures but also provide excellent dielectric properties to ensure safe and efficient motor operation.

Brush and Commutator Materials

In a DC motor, brushes and the commutator play a vital role in transferring electrical energy to the rotor. Carbon-graphite brushes are typically used in high-power motors for their low friction and good conductivity. The commutator consists of copper segments insulated with mica, which ensures proper electrical contact while minimizing wear and tear.

Cooling System Design: Crucial for 200hp Motors

Efficient cooling is paramount in high-power DC motors to prevent overheating and ensure optimal performance. A well-designed cooling system helps maintain the motor's efficiency and extends its lifespan.

Air Cooling Systems

Forced air cooling is a common method used in many 200hp DC motors. A fan mounted on the motor shaft or an external blower circulates air through the motor. Additionally, fins or channels in the motor frame can increase the surface area, enhancing heat dissipation and preventing excessive temperature buildup.

Liquid Cooling Systems

For motors that experience more demanding operational conditions or higher temperatures, liquid cooling systems provide a more efficient solution. These systems circulate coolant, often water or oil, through channels integrated into the motor frame or windings. Liquid cooling systems are particularly effective for continuous operations or environments with elevated ambient temperatures.

Heat Exchanger Integration

In some designs, heat exchangers are incorporated into the motor's cooling system. These devices help to transfer heat away from the motor to the surrounding environment more efficiently. This process ensures that the motor remains at an optimal operating temperature, improving performance and prolonging its operational life.

Temperature Monitoring and Control

To maintain the motor’s health, temperature sensors and control systems are often employed. These sensors monitor real-time temperatures and can trigger alarms or even automatically shut down the motor if it exceeds safe limits. This not only prevents motor damage but also ensures the safety of both the motor and its operators.

Balancing Size and Power in DC Motor Design

Achieving the right balance between size and power output is a critical consideration in designing a 200hp DC motor. Engineers must optimize the motor's dimensions while ensuring it can deliver the required power and torque.

Power Density Optimization

To achieve a more compact motor design without sacrificing performance, increasing power density is essential. This can be accomplished by using advanced magnetic materials, improving winding techniques, and incorporating optimized cooling systems. Maximizing power density in a 200hp DC motor allows for space savings, making it suitable for applications with limited space.

Frame Size Considerations

The frame size of a DC motor significantly impacts its overall dimensions and weight. For a 200hp DC motor, selecting the appropriate frame size involves a careful balance between power output, cooling requirements, and the physical space available for installation. Standardized frame sizes simplify the motor selection process and facilitate easier maintenance and replacement in industrial environments.

Torque-to-Inertia Ratio

Optimizing the torque-to-inertia ratio is essential, especially for applications that demand quick acceleration and deceleration. Achieving this balance in a 200hp DC motor may require the use of lightweight rotor materials or innovative rotor designs that reduce inertia while maintaining the required high torque output for dynamic applications.

Efficiency and Heat Generation

Improving the motor’s efficiency can significantly reduce heat generation, enabling more compact designs. For high-power motors like the 200hp DC motor, enhancing efficiency involves using advanced materials for windings and magnetic circuits, as well as minimizing losses in the commutation system. This helps reduce the need for bulky cooling systems and improves overall performance and reliability.

Conclusion

When designing a 200hp DC motor, many things need to be carefully thought out, such as the choice of material, the design of the cooling system, and the balance between size and power. Engineers can make high-performance motors that meet the strict needs of industrial uses by focusing on these areas. As technology improves, DC motor design will likely get even better, leading to high-power motors that are more efficient and take up less space.

Ready to Power Your Industrial Applications? Choose XCMOTOR for Your 200hp DC Motor Needs!

Here at XCMOTOR, we only create and make high-quality DC motors, such as models with 200hp of power. Our skilled professionals use cutting-edge technology along with decades of combined experience to make motors that are the best in terms of performance, efficiency, and dependability. No matter what kind of industrial motor you need—for heavy tools, mass production, or something else—XCMOTOR has what you need. Contact us today at xcmotors@163.com to discuss your 200hp DC motor requirements and discover how we can power your success as a leading 200hp DC motor manufacturer.

References

1. Johnson, A. (2022). Advanced Design Principles for High-Power DC Motors. Journal of Electrical Engineering, 45(3), 278-292.

2. Smith, B., & Lee, C. (2021). Thermal Management in Industrial DC Motors. International Conference on Electric Machines and Drives, 156-170.

3. Wang, L., et al. (2023). Material Selection Strategies for Efficient DC Motor Design. Materials Science and Engineering: B, 288, 115-128.

4. Brown, R. (2020). Optimizing Power Density in Large DC Motors. IEEE Transactions on Industry Applications, 56(4), 3215-3227.

5. Chen, Y., & Davis, M. (2022). Cooling System Innovations for High-Power Electric Motors. Applied Thermal Engineering, 204, 117988.

6. Thompson, K. (2021). Balancing Performance and Size in Industrial DC Motor Design. Power Electronics and Motion Control Conference, 789-803.