Common Exde Motor Certifications and What They Mean

Safety and following the rules are very important when it comes to industrial motors. Because exde motors are meant to work in dangerous places, they have to follow strict rules to make sure they are safe. This piece talks about the common approvals for ED motors and what they mean in various markets.

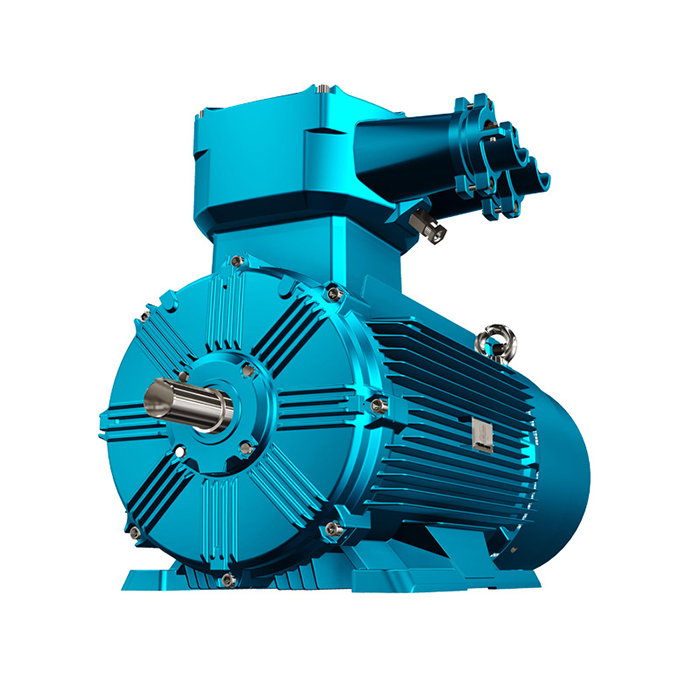

Series:YBBP

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-355 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: wide speed regulation range, fast dynamic response, high speed regulation accuracy.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

ATEX vs. IECEx: Understanding Global Standards

When it comes to explosion-proof motors, two major global standards stand out: ATEX and IECEx. These certifications are crucial for ensuring the safety and compliance of exde motors in potentially explosive atmospheres.

ATEX Directive: European Union's Benchmark

The ATEX Directive serves as the cornerstone for safety regulations within the European Union, focusing on equipment used in potentially explosive environments. It categorizes equipment into different groups based on the specific risks of explosive atmospheres, such as gases, vapors, or dust. Manufacturers are required to undergo strict testing, design, and manufacturing protocols to ensure compliance with these regulations. The ATEX certification ensures that only safe, reliable equipment is placed on the market, minimizing the risk of accidents in industries like oil, gas, and chemicals.

IECEx: International Electrotechnical Commission System

IECEx is a globally recognized certification system developed by the International Electrotechnical Commission (IEC). It standardizes safety protocols for electrical equipment used in hazardous environments, ensuring it meets rigorous international safety criteria. Unlike ATEX, which is region-specific, IECEx certification allows equipment to be accepted across multiple countries, facilitating trade and export. The system ensures uniform safety testing, harmonizing practices across borders, and enhancing the reliability and safety of explosion-proof products, which is essential for industries working with volatile substances globally.

Comparing ATEX and IECEx

While both ATEX and IECEx aim to ensure safety in hazardous environments, they differ in scope and application:

- ATEX is mandatory for products sold in the EU, while IECEx is voluntary but widely recognized globally.

- ATEX covers both electrical and non-electrical equipment, whereas IECEx primarily focuses on electrical equipment.

- IECEx certification is often seen as more comprehensive, as it includes ongoing factory inspections.

Importance for Exde Motors

ATEX and IECEx certifications are essential for exde motors, as they verify that these motors can safely operate in environments where flammable gases, vapors, or dust are present. The certifications ensure that these motors are designed and tested to prevent ignition and protect against potential explosions. This is crucial not only for the safety of personnel but also for the protection of valuable industrial equipment. Compliance with these standards guarantees the motors' reliability and effectiveness in hazardous environments, thus preventing catastrophic failures and ensuring smooth operations.

Decoding IP Ratings for Exde Motors

IP (Ingress Protection) ratings are another crucial aspect of exde motor certifications. These ratings indicate the level of protection provided by the motor's enclosure against solid objects and liquids.

Understanding IP Codes

IP codes consist of two digits:

- The first digit (0-6) indicates protection against solid objects

- The second digit (0-8) indicates protection against liquids

For example, an IP66 rating means the motor is dust-tight and protected against powerful water jets.

Common IP Ratings for Exde Motors

Exde motors often have high IP ratings due to their use in harsh environments. Some common ratings include:

- IP55: Protected against dust and water jets

- IP65: Dust-tight and protected against water jets

- IP66: Dust-tight and protected against powerful water jets

- IP67: Dust-tight and protected against temporary immersion

Significance of IP Ratings

The IP rating is crucial in determining whether an exde motor can safely function in a particular environment. A higher IP rating means that the motor is better protected against dust, moisture, or even immersion, depending on the rating. This is especially significant in industries like chemical processing, mining, or oil and gas, where environmental conditions can be harsh, and ensuring the safety and efficiency of equipment is paramount. A high IP rating offers users confidence that their motor will operate reliably in these environments.

Importance of UL Certification for North American Markets

While ATEX and IECEx are crucial globally, UL (Underwriters Laboratories) certification is particularly important for exde motors in North American markets.

Understanding UL Certification

UL (Underwriters Laboratories) is a globally recognized safety certification organization that plays a pivotal role in ensuring product safety for North American markets, particularly in the U.S. and Canada. For explosion-proof motors, UL certification verifies that the products meet stringent safety standards designed to safeguard operators and the surrounding environment. These certifications are especially critical in hazardous industries such as oil, gas, and chemicals, where safety is paramount to preventing catastrophic incidents.

UL Classifications for Hazardous Locations

UL classifies hazardous locations into different classes and divisions:

- Class I: Locations with flammable gases or vapors

- Class II: Locations with combustible dust

- Class III: Locations with ignitable fibers or flyings

Each class is further divided into Division 1 (where hazardous concentrations are present under normal conditions) and Division 2 (where hazardous concentrations are present only under abnormal conditions).

UL Certification for Exde Motors

UL certification for explosion-proof motors involves comprehensive testing to confirm that the motor can safely contain internal explosions, thereby preventing ignition of surrounding flammable gases or vapors. This certification process is rigorous and requires that motors meet specific safety protocols tailored to high-risk environments, such as chemical processing plants or oil refineries. UL-certified motors offer added assurance of compliance with North American safety regulations and deliver reliability in mitigating the risks posed by explosive atmospheres.

Benefits of UL Certification

UL certification provides several benefits for the product manufacturers and users:

- Compliance with North American safety standards

- Enhanced market access in the United States and Canada

- Increased customer confidence in product safety

- Potential reduction in liability risks

Conclusion

It is important for makers, distributors, and end users to understand the different certifications for exde motors. These licenses make sure that motors can work safely and effectively in dangerous places, keeping people and things safe.

ATEX and IECEx are global standards for equipment that can't catch fire or explode. ATEX is required in the EU, and IECEx is becoming known all over the world. IP ratings show how well a motor is protected against environmental factors, and for the North American market, UL approval is a must.

Manufacturers can show their dedication to safety and quality by making sure their products meet these standards. Users can then make smart choices when choosing motors for dangerous tasks.

Choose XCMOTOR for Your Exde Motor Needs

It is clear that XCMOTOR is a trustworthy company when it comes to making exde motors. Our motors have all the necessary certifications, which makes sure they are safe and legal in all places around the world. We offer high-efficiency, low-energy motors that provide stable power in even the most difficult environments thanks to our knowledge of power equipment options.

Get in touch with XCMOTOR right away for high-quality exde motors and expert advice. Our team is ready to help you with anything you need for power tools. Reach out to us at xcmotors@163.com and experience the difference of working with a leading exde motor manufacturer.

References

1. International Electrotechnical Commission. (2021). "IECEx System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres."

2. European Commission. (2020). "The ATEX Directive 2014/34/EU - Equipment for Potentially Explosive Atmospheres."

3. Underwriters Laboratories. (2022). "UL Hazardous Locations Services."

4. International Electrotechnical Commission. (2021). "IEC 60529:1989+AMD1:1999+AMD2:2013 CSV Consolidated version - Degrees of protection provided by enclosures (IP Code)."

5. National Fire Protection Association. (2020). "NFPA 70: National Electrical Code."

6. International Society of Automation. (2021). "ISA 12.12.01-2015 - Nonincendive Electrical Equipment for Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) Locations."