The Benefits of Low Voltage Induction Motors for Small Systems

Small industrial systems need mechanical solutions that are safe, efficient, and cost-effective. For these uses, low voltage induction motors are the best option because they provide constant performance while keeping operations simple. Within 380V±5% power ranges, these electric motors work well, which makes them ideal for small manufacturing setups, process control systems, and automatic machinery. These three-phase motors are very flexible and can handle a wide range of industry needs thanks to their 45–800kW power range. Because of the way it is built, induction motor technology gives small devices reliable operation, less upkeep, and very high energy efficiency, all of which have a direct effect on running costs.

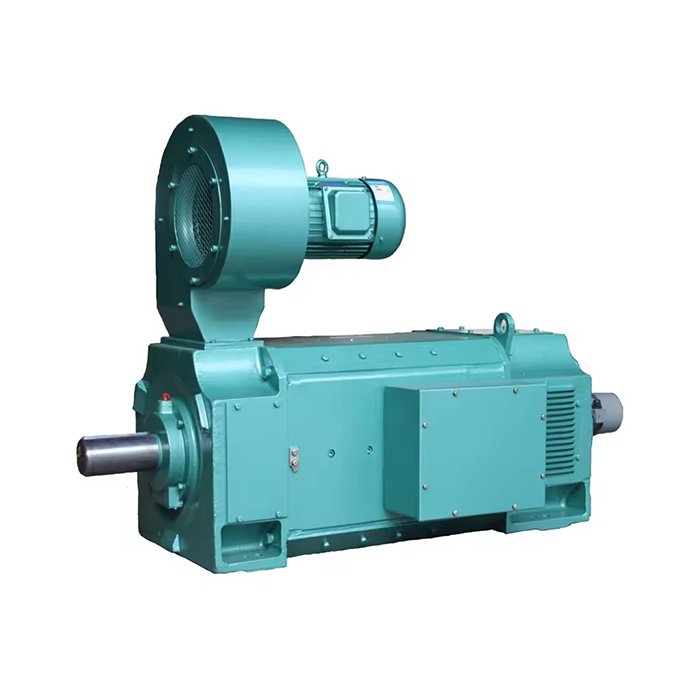

Series:YRQ

Voltage range:380V±5%

Power range:45-800kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Key Performance Parameters

Voltage and Frequency Compatibility

Maintaining compliance with typical industrial power supply networks is ensured by the operating voltage of 380V±5%. A frequency range of fifty to sixty hertz (Hz) or sixty hertz (Hz) is suitable for worldwide electrical standards and provides a wide range of flexibility.

Speed Control and Power Ratings

The capabilities of speed control span from 500 to 1500 revolutions per minute, in order to provide operational flexibility. Small to medium industrial applications are covered by power ratings ranging from 45 kW to 800 kW, which provides a wide range of potential solutions to meet a variety of requirements.

Protection Level and Environmental Suitability

These motors have a protection rating of IP23, which means that they are protective against solid particles that are bigger than 12.5 millimetres and water spray that falls within a range of 60 degrees. Higher levels of protection are not required in dry, dust-free indoor situations, which are perfect for this level.

Cooling and Insulation Efficiency

Maintaining appropriate operating temperatures without the need for elaborate cooling systems is the goal of the IC01 cooling technology, which makes advantage of natural air movement. It is possible for insulation class B to tolerate temperatures of up to 130 degrees Celsius, which guarantees its dependability even in the most demanding of circumstances.

Performance and Reliability

When put together, these technological requirements make motors that reliably operate in a variety of industrial settings by delivering consistent performance with very little complexity.

Core Benefits That Transform Small System Operations

Enhanced Operational Efficiency

By using the electromagnetic field that exists between the stator and the rotor, low voltage induction motors are able to provide improvements in operating efficiency. As a consequence of this contactless design, mechanical wear is reduced, which in turn results in fewer maintenance requirements.

Energy Optimization and Soft Starting

The design of the slip ring or squirrel cage rotor also contributes to the optimisation of energy use. By decreasing power demand spikes and increasing the lifetime of equipment, soft starting qualities safeguard the motor and the equipment from the effects of electrical stress.

Thermal Protection and Self-Safety

In order to prevent the motor from overheating, thermal safety elements are designed to have the motor shut down automatically when temperatures reach safe levels. It is essential for tiny systems to have this capacity of self-protection since continuous monitoring may not be possible in such systems.

Robust Durability and Vibration Resistance

The motor is able to handle industrial vibrations and environmental stressors thanks to the sturdy cast iron frame design, which also significantly improves its mechanical endurance. This ensures that the motor will last for a long time and work consistently.

Seamless Integration with Automation Systems

It is possible to combine motor control systems with current industrial automation platforms without any problems. Even when the circumstances of the power supply are variable, accurate operation and reliable performance are possible thanks to the availability of speed control choices and voltage regulation.

XCMOTOR's Advanced Low Voltage Solutions vs Standard Market Options

Premium Copper Components for Enhanced Efficiency

When compared to aluminium, the rotor and stator windings of the YRQ(JR) series motors manufactured by XCMOTOR are made of copper, which provides high electrical conductivity. As a result, the motor's operating life is extended, its efficiency is improved, and heat dissipation is enhanced.

Precision-Balanced Rotors for Vibration Reduction

The vibration problems that are often associated with ordinary motors are eliminated by the precision-balanced rotors that are included in our Low Voltage Induction Motor. By doing so, the operation becomes more smooth, the mechanical stress placed on linked equipment is minimized, and the lifetime of the system is increased.

High-Quality Bearing Options for Reliability

SKF, NSK, and FAG are just some of the well-known brands that XCMOTOR offers superior bearings and accessories. The motor's durability and performance are both improved by these high-quality bearings, which outlive typical components and reduce the regularity of maintenance intervals. Through customisation, bearings may be optimised and adapted to precisely meet the requirements of a given operating environment.

Versatile Mounting Configurations for Easy Installation

The foot-mounted, flange-mounted, and combined foot-flange mounting choices are just some of the mounting configurations that our three-phase slip ring induction motors are intended to support. This versatility makes installation easier with smaller systems that have a restricted amount of footprint.

Consistent Quality Through Advanced Manufacturing

Manufacturing processes that are at the cutting edge of technology guarantee a consistent and high-quality production throughout our whole line of motors. These motors provide dependable performance and durability for applications that are particularly demanding in the industrial sector.

Maximizing Performance Through Proper Implementation

Proper Alignment and Installation Practices

When it comes to minimising premature bearing failure and decreasing energy consumption, appropriate alignment between the motor and the equipment that is being driven is very necessary. To maintain a smooth performance and to extend the lifetime of the motor, proper installation is essential.

Environmental Considerations for Efficiency and Longevity

When it comes to motor efficiency and lifetime, the ambient temperature and ventilation are two factors that play a considerable impact. Monitoring environmental conditions and ensuring that there is sufficient ventilation are both helpful in maintaining good motor function.

Power Supply Quality and Voltage Regulation

The quality of the power source dictates the performance of the Low Voltage Induction Motor. Voltage variations that exceed the limit of ±5% might result in efficiency losses and overheating. Establishing a constant functioning and providing protection against electrical disruptions are both benefits of installing voltage regulating equipment.

Regular Maintenance for Reliability

Routine maintenance, such as bearing lubrication, checking connection tightness, and insulation testing, helps identify potential issues before they result in system downtime. Periodic cleaning of the IC01 cooling method ensures proper airflow around the motor.

Proper Motor Sizing for Optimal Efficiency

Avoid under-loading or overloading the motor to ensure optimal efficiency. Matching motor characteristics to application requirements maximizes energy consumption efficiency and ensures performance margins are met. Professional consultation helps in selecting the most suitable motor specifications for small system applications.

Essential Considerations for Optimal Operation

Environmental Factors Affecting Performance and Longevity

Operating temperatures between -20°C and +40°C are standard, but extreme temperature variations require special considerations. Humidity levels can affect insulation performance, making proper ventilation essential in humid environments.

Electrical Considerations for System Efficiency

Beyond basic voltage requirements, power factor correction may be needed in installations with multiple motors to optimize overall electrical system efficiency. In some cases, soft-start equipment is necessary to manage starting current limitations in installations with limited electrical capacity.

Load Characteristics and Motor Selection

The nature of the load—whether constant torque or variable torque—plays a critical role in motor selection. Understanding load profiles ensures motor efficiency is optimized and helps prevent operational issues that could affect system productivity.

Safety Protocols for Electrical and Mechanical Hazards

Safety measures should address both electrical and mechanical hazards. Proper grounding, lockout/tagout procedures, and emergency stop systems are essential to protect personnel and ensure compliance with safety regulations. Regular safety training keeps operators aware of hazards and proper procedures.

Conclusion

Low voltage induction motors provide small systems with reliable, efficient, and cost-effective mechanical power solutions. The combination of proven technology, robust construction, and operational simplicity makes these motors ideal for diverse industrial applications. XCMOTOR's commitment to quality components, precision manufacturing, and comprehensive customer support ensures optimal performance for your small system requirements. Investing in properly specified and maintained low voltage induction motors delivers long-term operational benefits that justify initial costs through reduced energy consumption, minimal maintenance demands, and exceptional reliability.

Frequently Asked Questions

Q1: What power range works best for small industrial systems?

A: Most small systems operate efficiently with motors in the 45-200kW range. This power level provides adequate capacity for typical applications like pumps, compressors, and conveyor systems while maintaining reasonable electrical infrastructure requirements. Higher power motors up to 800kW suit larger small systems or applications requiring significant mechanical output.

Q2: How does IP23 protection benefit small system installations?

A: IP23 protection offers optimal balance between environmental protection and cost-effectiveness for indoor applications. This rating prevents solid particles larger than 12.5mm from entering the motor while protecting against water spray from any direction up to 60 degrees. The open ventilation design provides 15-20% better heat dissipation than fully enclosed motors.

Q3: What maintenance requirements should small system operators expect?

A: Regular maintenance includes bearing lubrication every 3-6 months depending on operating conditions, quarterly electrical connection inspections, and annual insulation testing. The cast iron frame construction and quality bearings minimize maintenance demands compared to lighter-duty motors. Proper ventilation maintenance ensures optimal cooling performance throughout the motor's operational life.

Get Started with XCMOTOR's Reliable Low Voltage Motor Solutions

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. delivers comprehensive power equipment solutions tailored for small system applications. Our experienced team understands the unique challenges facing compact industrial operations and provides expert guidance for motor selection and implementation. As a trusted low voltage induction motor supplier, we offer original components from premium brands, ensuring reliable operation and extended service life. Our commitment includes fast delivery, 30-day return policies, and dedicated support seven days per week. Contact us at xcmotors@163.com to discuss your specific requirements and discover how our solutions can enhance your small system operations.

References

1. Chapman, Stephen J. "Electric Machinery Fundamentals, Fifth Edition." McGraw-Hill Education, 2012.

2. Fitzgerald, A.E., Charles Kingsley Jr., and Stephen D. Umans. "Electric Machinery, Sixth Edition." McGraw-Hill Higher Education, 2003.

3. Sen, P.C. "Principles of Electric Machines and Power Electronics, Third Edition." John Wiley & Sons, 2013.

4. IEEE Standards Association. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017.

5. Nasar, S.A. and L.E. Unnewehr. "Electromechanics and Electric Machines, Third Edition." John Wiley & Sons, 1993.

6. Boldea, Ion and Syed A. Nasar. "The Induction Machine Handbook." CRC Press, 2002.