How IP23 Motors Perform in Dusty and Wet Environments?

Safety standards are important to know when working with electricity in a tough workplace setting. Motor IP23 units guard against dust particles larger than 12.5 mm and water splashes from up to 60 degrees above vertical. They keep the right amount of air flow to get rid of heat and work well in fairly hard conditions. Higher-rated motors can keep out more dust than IP23 motors, but IP23 motors work great in controlled indoor settings where basic safety is enough to get the job done without losing cooling efficiency.

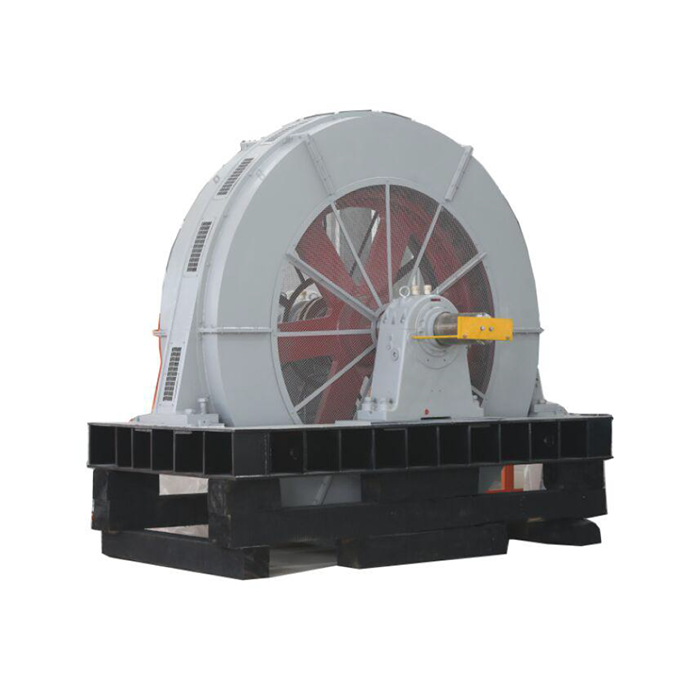

Series:Y

Voltage range: 380V±5%

Power range: 55~355 kW

Protection level:IP23

Application: This series of motors can be used to drive various machinery. Such as ventilators, compressors, water pumps, crushers, cutting machine tools and other equipment, and can be used as prime movers in coal mines, machinery industries, power plants and various industrial and mining enterprises.

Advantage: This series of motors has the advantages of high efficiency, energy saving, low noise, small vibration, light weight, reliable performance, and convenient installation and maintenance.

Certificate: The motor complies with JB5271-91

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding IP23 Protection Standards

Overview of IP23 Rating

The IP23 rating defines the environmental protection level for motors in industrial applications, specifying the types of challenges these motors can safely withstand.

Solid Object Protection (IP2X)

The "IP2X" component protects against solid foreign objects larger than 12.5mm in diameter, such as workshop debris, tools, and larger dust particles. However, finer dust can still penetrate the motor housing.

Water Protection (IPX3)

The "IPX3" component provides splash protection from water spray at angles up to 60 degrees from vertical. This level is suitable for accidental water exposure, such as during cleaning or light moisture in the environment.

Heat Dissipation Advantage

IP23 motors offer better heat dissipation compared to fully enclosed designs. The open ventilation structure allows for 15-20% better cooling, preventing heat retention while still providing adequate environmental protection.

Core Applications Where IP23 Motors Excel

Ventilation Systems in Manufacturing Plants

Motor IP23 is used in manufacturing facilities to keep work areas ventilated. They can handle some dust and wetness from humidity control. Automobile companies use them to ventilate paint booths. The splash-proof design keeps overspray from happening, and the better heat reduction makes sure they work reliably during continuous operation cycles.

Compressor Operations in Processing Industries

Compressed air systems in food processing plants use IP23 motors to power pneumatic equipment's fans while also being resistant to dust and able to handle washdowns. As long as they are exposed to processing leftovers and cleaning chemicals within the safety limits, these motors can reliably power compressors in chemical plants.

Water Pumping Systems

Municipal water treatment plants use IP23 motors for pumping tasks because they are durable and protect against splashes in wet places. These motors are used in industrial cooling systems for circulation pumps. Electrical safety features keep the pumps dry, and the cooling design keeps them from getting too hot during long operations.

Material Handling Equipment

IP23 motors are used in warehouses to move things reliably on conveyor lines. The dust resistance can handle dust from packaging materials and goods while keeping the machine running smoothly. Debris can't damage the motor's internal parts because of the motor case.

The proper safety that these motors provide is good for packaging machines. The longevity makes sure that the performance stays the same even when it's exposed to cardboard dust and glue particles, which are common in packing settings.

Machine Tool Applications

Motor IP23 units are used for a variety of tasks in precision industrial tools. Cutting tools, grinding machines, and other machines that need to work reliably are powered by these motors. The motor safety keeps metal bits and cutting fluids from getting into the motor and affecting its accuracy.

Woodworking facilities use these motors extensively due to their ability to handle sawdust and wood particles larger than 12.5mm. The water splash proof design protects against cleaning operations while the enhanced ventilation prevents overheating from continuous use.

HVAC Systems in Commercial Buildings

Commercial heating, ventilation, and air conditioning systems rely heavily on IP23-rated motors. These units power air handling equipment throughout office buildings, schools, and retail facilities. The environmental protection ensures reliable operation despite varying indoor conditions.

The motor efficiency characteristics reduce energy consumption while providing consistent climate control. Building operators appreciate the reduced maintenance requirements and extended service life these motors provide in demanding commercial applications.

Power Generation Support Equipment

Electrical power plants use Motor IP23 units for auxiliary equipment operations. These motors power cooling fans, fuel handling systems, and other support equipment critical to power generation. The safety compliance features ensure reliable operation in industrial power environments.

Renewable energy installations incorporate these motors in various support systems. Wind farms use them for tower ventilation and equipment cooling, while solar installations rely on them for tracking system operations.

Performance Characteristics in Challenging Environments

Dusty Conditions and Cooling Efficiency

Motor IP23 units are designed to perform in dusty environments, with a 2X protection level that blocks larger particles while allowing smaller dust to circulate through the motor housing. This design prioritizes cooling efficiency over complete dust exclusion.

Maintenance in Dusty Environments

In dusty conditions, regular maintenance is crucial to prevent the buildup of fine particles on motor windings. The open ventilation design simplifies cleaning procedures compared to fully sealed motors, making upkeep more manageable.

Wet Environment Performance

While these motors can handle incidental water exposure, they require protection from direct water spray outside the 60-degree vertical range. The motor's insulation system is resistant to moisture damage within the specified protection parameters.

Temperature Management and Heat Dissipation

Compared to fully enclosed designs, IP23 motors offer significantly better temperature management. Enhanced heat dissipation prevents thermal stress on motor components, extending their service life in demanding applications. This cooling advantage often outweighs the reduced environmental protection in controlled industrial settings.

Installation and Maintenance Considerations

Installing IP23 motors correctly protects them from the environment by keeping them away from high-pressure water spray and making sure they can drain properly. Enough space for air is necessary for heat to escape. Maintenance plans should take into account the environment, with dusty places needing more cleaning. The IP23 motors' open form makes maintenance easier. When bearings are out in the open, they need to be oiled and inspected on a regular basis to keep them running smoothly and reduce friction.

Comparing IP23 with Other Protection Ratings

Protection Level Comparison

The environmental protection provided by IP23 motors is acceptable, but the dust and water resistance provided by IP54 motors is exceptional. On the other hand, IP54 motors are more expensive and decrease the efficiency with which they cool the motor.

Mechanical Robustness

Due to the fact that they are constructed to an industrial standard, IP23 motors often surpass expectations in terms of their mechanical resilience. Despite the fact that environmental protection is only modest, the structural integrity is perfect for applications that need severe mechanical work.

Energy Efficiency

The energy efficiency of IP23 motors is exceptional in situations that are suited for their use. The exceptional cooling properties that they possess lower operating temperatures, which in turn improves electrical efficiency and extends the lifespan of components.

Cost-Performance Analysis

IP23 motors offer significant cost advantages in the right applications, providing adequate protection at a lower price compared to higher-rated alternatives. This makes them a great choice for facilities looking for effective performance without premium costs.

Safety and Compliance Aspects

Electrical Safety Standards

IP23 motors are designed to comply with electrical safety regulations, which guarantees the protection of workers while guaranteeing that they continue to function reliably in situations of mild exposure.

Installation Codes and Protection Requirements

Installation codes often specify minimum protection standards for various industrial applications. IP23 motors meet these requirements, offering enhanced cooling and operational advantages in many scenarios.

Worker Safety Considerations

Proper training is essential to ensure that personnel understand the limitations of IP23 protection. Workers must be aware of the motor’s operating conditions and maintenance procedures for safe operation.

Documentation for Safety Compliance

Facilities must maintain documentation that identifies protection ratings and operational limits. Records must demonstrate the proper application of Motor IP23 within their design parameters for safety compliance.

Troubleshooting Common Issues

Environmental Protection Failures

Failures occur when IP23 motors are exposed beyond their design limits. Early recognition of these conditions helps prevent extensive damage and ensures continued operational reliability.

Moisture-Related Problems

Moisture can cause insulation resistance changes and bearing contamination. Regular testing helps identify these issues before they lead to operational failures.

Dust Accumulation

In high-particulate environments, dust buildup can gradually affect performance. Establishing cleaning schedules based on actual operating conditions helps prevent degradation.

Overheating Issues

Overheating may be caused by blocked ventilation or excessive environmental loads. Identifying and addressing the root causes ensures optimal motor performance and prevents premature failure.

Economic Benefits of IP23 Motor Selection

IP23 motors offer cost advantages with their initial affordability, providing necessary protection without the premium cost of higher-rated alternatives. Operating costs are reduced through improved cooling and lower maintenance needs. Their superior thermal management often results in longer service life, ensuring a good return on investment. Standardized parts and widespread usage make replacement and maintenance supplies readily available, lowering long-term ownership costs.

Conclusion

Motor IP23 units provide balanced environmental protection that suits many industrial applications. These motors offer adequate dust and water resistance while maintaining superior cooling capabilities compared to fully enclosed alternatives. The key to successful implementation lies in matching motor capabilities with actual environmental conditions. When properly applied, IP23 motors deliver reliable performance, reduced operating costs, and simplified maintenance procedures. Understanding their limitations and advantages enables facilities to make informed decisions that optimize both protection and performance for their specific operational requirements.

Frequently Asked Questions

1. Can IP23 Motors Handle Fine Dust Environments?

Motor IP23 units provide limited protection against fine dust particles. The 2X rating blocks objects larger than 12.5mm but allows smaller particles to enter the motor housing. Regular cleaning becomes necessary in environments with significant fine dust concentrations.

2. What Water Exposure Can IP23 Motors Withstand?

These motors handle water spray from angles up to 60 degrees from vertical. Direct high-pressure washing or immersion exceeds the protection capabilities and may cause damage. Incidental splashing from cleaning operations typically poses no problems.

3. How Often Should IP23 Motors Receive Maintenance?

Maintenance frequency depends on environmental conditions and operating demands. Generally, quarterly inspections suffice for moderate environments, while monthly checks benefit motors in challenging conditions. The open design simplifies inspection and cleaning procedures.

4. Do IP23 Motors Work in Outdoor Applications?

Outdoor use requires careful consideration of weather protection. These motors need shelter from direct precipitation and extreme weather conditions. Covered outdoor installations may work successfully with proper environmental controls.

5. Can IP23 Motors Replace Higher-Rated Units?

Replacement depends on specific application requirements and environmental conditions. IP23 motors may substitute for higher-rated units where environmental challenges fall within their protection capabilities and improved cooling provides operational benefits.

6. What Temperature Ranges Can IP23 Motors Handle?

Operating temperature ranges vary by specific motor design and manufacturer specifications. Generally, these motors handle standard industrial temperature ranges effectively due to their superior cooling characteristics compared to enclosed designs.

Partner with XCMOTOR for Your Industrial Motor Needs

Ready to optimize your industrial operations with reliable Motor IP23 solutions? XCMOTOR specializes in providing high-quality three phase slip ring induction motors designed for demanding industrial environments. Our experienced team understands the unique challenges your facility faces and can recommend the perfect Motor IP23 supplier solution. Contact our dedicated support team at xcmotors@163.com to discuss your specific requirements and discover how our premium motor solutions can enhance your operational efficiency while reducing long-term costs.

References

1. International Electrotechnical Commission. "Degrees of Protection Provided by Enclosures (IP Code)." IEC 60529 Standard for Electrical Equipment Protection Classifications.

2. National Electrical Manufacturers Association. "Motors and Generators: Application Guide for Three-Phase Induction Motors." NEMA MG 1 Standards Publication.

3. Institute of Electrical and Electronics Engineers. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112 Motor Testing Guidelines.

4. American Society of Heating, Refrigerating and Air-Conditioning Engineers. "Industrial Ventilation Motor Selection and Environmental Protection Standards." ASHRAE Applications Handbook.

5. International Organization for Standardization. "Rotating Electrical Machines: Classification of Degrees of Protection Provided by Enclosures." ISO 20653 Protection Standards.

6. Electrical Apparatus Service Association. "Recommended Practice for Motor Protection in Industrial Environments." EASA Technical Manual for Motor Applications.