Slip ring rotor motors represent essential equipment in paper and pulp mill operations, providing the robust power solutions needed for demanding industrial processes. These specialized motors excel in applications requiring high starting torque, variable speed control, and reliable performance under heavy load conditions. Paper and pulp mills rely on these motors to drive critical machinery including refiners, digesters, conveyors, and various processing equipment. The unique design of wound rotor motors allows operators to adjust starting characteristics and speed control through external resistance, making them particularly valuable in mill environments where precise control and dependable operation directly impact production efficiency and product quality.

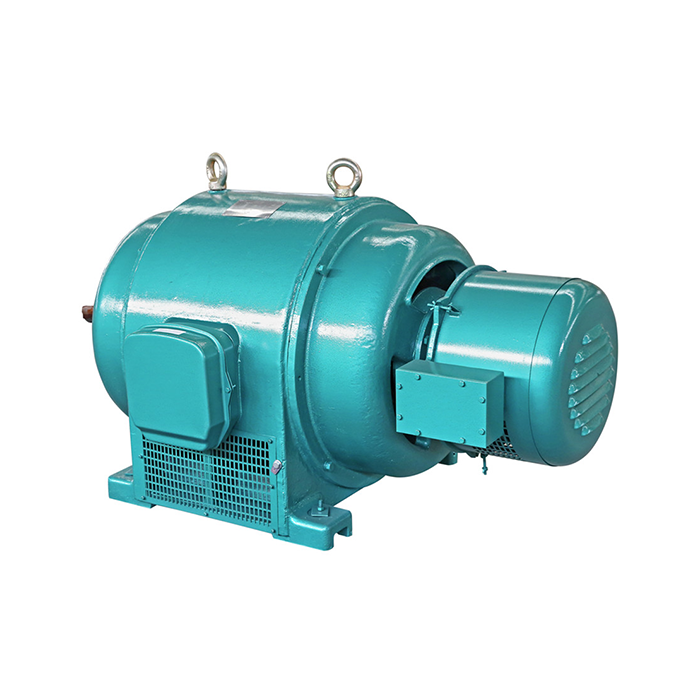

Series:YRQ

Voltage range:380V±5%

Power range:45-710kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Slip Ring Rotor Motors in Paper and Pulp Mills

The paper and mash industry requests engines that can withstand cruel working conditions whereas conveying reliable execution over different applications. Wound rotor engines meet these necessities through their specialized development and operational characteristics that set them separated from standard acceptance motors.

Basic Construction and Working Principle of Slip Ring Rotor Motors

These engines utilize slip–ring–connected rotor windings with outside resistance for controlled startup and speed control, lessening inrush current, conveying tall torque, and empowering effective speeding up, making them perfect for paper process applications.

Key Advantages in Paper and Pulp Industry Applications

Paper and mash plants advantage essentially from the operational preferences these engines give. The capacity to produce tall beginning torque, up to 280% of evaluated torque, demonstrates basic for overwhelming apparatus startup in process environments.

Here are the core advantages these motors deliver in mill operations:

- Superior starting characteristics: The external resistance control allows smooth startup of heavy machinery such as digesters and refiners without causing electrical system disruption, while maintaining torque levels necessary to overcome initial load resistance.

- Variable speed operation: Mills can adjust processing speeds to match production requirements, optimizing fiber processing quality and energy consumption while maintaining precise control over critical manufacturing parameters.

- Reduced mechanical stress: Gradual acceleration capabilities minimize shock loads on connected machinery, extending equipment life and reducing maintenance requirements across the production line.

- Overload tolerance: Enhanced capacity to handle temporary overload conditions common in mill operations, particularly during material feeding variations or process adjustments.

These advantages translate directly into improved operational reliability and production consistency, addressing the demanding requirements of modern paper manufacturing facilities.

Typical Applications within Paper and Pulp Mills

These motors support key paper mill operations—from wood chippers and pulp refiners to machine drives and conveyors—delivering variable speed, high torque control, and smooth starting to maintain product quality and operational reliability.

Comparing Slip Ring Rotor Motors with Other Motor Types for Paper and Pulp Mills

Selecting fitting engine innovation requires understanding how distinctive engine sorts perform beneath particular process working conditions. Each engine innovation offers unmistakable focal points and confinements that influence their appropriateness for different paper process applications.

Slip Ring Rotor Motor vs Squirrel Cage Motor: Which Is Better for Heavy Loads?

Squirrel cage motors require added controls for heavy load starts, while slip ring rotor motor technology offers built-in torque control and adjustable speed without electronics, making it advantageous for demanding mill applications despite higher maintenance needs.

Slip Ring Rotor Motor vs Induction and Synchronous Motors

Induction and synchronous engines need outside resistance control or require complex frameworks, while wound rotor innovation superior underpins visit begins and variable speed needs, complementing constant-speed synchronous applications inside paper and mash mills.

When to Choose Slip Ring Rotor Motors over Brushless and Permanent Magnet Motors

Brushless and permanent magnet motors deliver efficiency and precision but come with higher costs and complexity. Slip ring rotor motor solutions remain cost-effective for high-torque starts, basic speed control, and harsh mill environments.

Enhancing Operational Efficiency and Reliability of Slip Ring Rotor Motors

Maximizing engine execution and benefit of life requires executing comprehensive support methodologies custom fitted to process working conditions. Appropriate upkeep has a significant effect on engine reliability and operational costs.

Maintenance Best Practices for Prolonged Motor Life

Regular review plans ought to center on basic wear components, including brushes, slip rings, and heading. Brush condition requires to month-to-month assessment, with substitution suggested when brush length comes to least details. Slip ring surfaces require normal cleaning to keep up legitimate electrical contact and avoid excessive wear.

Lubrication change based on bearing sort and working conditions. Our YRQ arrangement engines oblige SKF, NSK, and FAG heading concurring to client necessities, with each bearing producer giving particular oil suggestions. Appropriate grease intervals and amounts avoid untimely bearing disappointment and decrease support costs.

Winding cover checking through schedule testing makes a difference in distinguishing potential issues some time recently they cause engine disappointment. Separator resistance estimations and vibration examination give early caution of developing issues, permitting arranged support or maybe than crisis repairs.

Common Troubleshooting Scenarios Specific to Pulp and Paper Mill Conditions

Mill situations display one-of-a-kind challenges, including cleanliness, dampness, and chemical presentation that influence engine execution. Brush starting regularly demonstrates defilement, disgraceful brush review, or slip ring surface issues. Customary cleaning and appropriate brush determination based on working conditions minimize these issues.

Overheating issues often as possible result from blocked ventilation, bearing issues, or excessive encompassing temperatures. Our engines highlight IC01 cooling strategies outlined for mechanical situations, but legitimate ventilation clearances remain basic for satisfactory warm dissipation.

Vibration issues may show bearing wear, rotor imbalance, or mechanical misalignment. Early discovery through scheduled vibration checking anticipates disastrous disappointments and diminishes repair costs.

Optimizing Motor Efficiency for Cost Savings and Environmental Compliance

Energy management strategies focus on matching motor operation to actual load requirements. Proper resistance adjustment during operation maintains optimal efficiency while providing necessary speed control. Regular power monitoring identifies opportunities for operational improvements and energy savings.

Our motors operate within voltage ranges of 380V±5% and power ranges from 45-800kW, providing flexibility for various mill applications while maintaining efficiency standards. Proper motor sizing ensures optimal efficiency across the expected load range, preventing oversized installations that waste energy.

Procurement Considerations: Sourcing Slip Ring Rotor Motors for Paper and Pulp Mills

Successful motor procurement requires understanding technical specifications, supplier capabilities, and long-term support requirements. Mills must evaluate multiple factors beyond initial purchase price to ensure optimal total cost of ownership.

Key Specifications and Customization Options to Consider

Match power, voltage, and protection levels to mill environments, with customization enhancing durability and performance for slip ring rotor motor applications requiring specific installation adaptations.

Leading Global Suppliers and Brand Comparisons

Evaluate supplier capabilities, certifications, and service networks to ensure reliable slip ring rotor motor performance, reduced downtime, and consistent technical support over long-term operation.

Purchase Process, Pricing, Lead Time, and Delivery Logistics

Plan early to manage lead times, consider total ownership cost beyond price, and leverage volume purchasing for optimized specifications and contractual benefits.

Case Studies and Future Prospects in Paper and Pulp Industry

Real-world applications demonstrate the practical benefits wound rotor motors provide in paper mill environments, while emerging technologies offer additional optimization opportunities.

Successful Slip Ring Rotor Motor Implementations in Major Mills

Upgraded slip ring rotor motor systems improved production consistency, reduced maintenance, and minimized mechanical stress during startups in critical refiner and conveyor applications.

Emerging Trends: Integration with Automation and Digital Monitoring

Automation integration enables real-time monitoring, predictive maintenance, and operational optimization, reducing downtime and improving energy management.

Future Developments: Advancements in Motor Design for Paper and Pulp Applications

Enhanced materials, improved cooling, and intelligent controls increase motor durability, efficiency, and adaptability for evolving paper mill requirements.

Company Introduction & Product Service Information

Shaanxi Qihe Xicheng Electromechanical Gear Co., Ltd. specializes in giving comprehensive control hardware arrangements for overwhelming mechanical applications, including paper and mash plants. Our ability includes engine choice, customization, and progressing specialized back to guarantee ideal execution in demanding process environments.

Our YRQ arrangement engines highlight strong development, particularly outlined for mechanical applications, with control ranges from 45-800kW and voltage alternatives of 380V and 660V. These engines give the tall beginning torque and speed control capabilities basic for paper process applications, supported by comprehensive specialized support and worldwide conveyance capabilities.

We offer total customization capabilities including bearing details (SKF, NSK, FAG), electrical arrangements, and natural assurance levels to coordinate particular process requirements. Our commitment expands past item conveyance to incorporate installation support, commissioning help, and continuous technical support to maximize engine execution and extend life.

Conclusion

Slip ring rotor motors continue serving as essential equipment in paper and pulp mill operations, providing the robust performance and control capabilities these demanding applications require. Their ability to deliver high starting torque, variable speed control, and reliable operation under heavy loads makes them particularly valuable for critical mill processes, including refiners, conveyors, and processing equipment.

Successful usage requires careful consideration of engine determinations, support hones, and provider determination to guarantee ideal execution and benefit life. As plants progress, receiving progressive observing and control advances, wound rotor engines remain significant through their compatibility with advanced computerization frameworks,s whereas keeping up their characteristic operational advantages.

Frequently Asked Questions

Q1: What are the main advantages of using slip ring rotor motors in paper and pulp mills?

A: These engines give tall beginning torque up to 280% of evaluated torque, amazing speed control capabilities, and solid operation beneath overwhelming load conditions. They offer smooth beginning characteristics that anticipate electrical framework disturbance and mechanical push on associated gear, while giving the variable speed control essential for optimizing paper generation processes.

Q2: How often should slip ring rotor motors be maintained in industrial applications?

A: Brush assessment ought to happen month to month, with substitution when brush length comes to least details. Slip ring cleaning and bearing grease take after producer proposals, regularly each 3-6 months depending on working conditions. Normal separator testing and vibration checking give early caution of potential problems.

Q3: Can slip ring rotor motors be customized for specific pulp and paper mill processes?

A: Yes, our engines suit different customizations counting bearing details (SKF, NSK, FAG choices), voltage appraisals (380V, 660V), control ranges (45-800kW), and natural security levels. Electrical associations, mounting arrangements, and cooling strategies can be altered to coordinate particular process prerequisites and working conditions.

Partner with XCMOTOR for Reliable Slip Ring Rotor Motor Solutions

XCMOTOR manufactures motors for paper and pulp mills that meet strict criteria. Our industrial motor application expertise assures you obtain equipment that matches your precise requirements and performs well over time. As a trusted slip ring rotor motor supplier, we provide comprehensive support from initial specification through installation and ongoing maintenance. Our YRQ series motors feature advanced manufacturing processes including precision winding and vacuum pressure impregnation for enhanced durability and performance. With power ranges from 45-800kW and customizable features including premium bearing options, our motors adapt to your specific application requirements.

Ready to optimize your mill operations with reliable motor solutions? Visit motorxc.com for detailed specifications and application guidance, or contact us at xcmotors@163.com to discuss your specific requirements with our technical specialists.

References

1. Chapman, Stephen J. "Electric Machinery Fundamentals." McGraw-Hill Education, 2012.

2. Fitzgerald, A.E., Charles Kingsley Jr., and Stephen D. Umans. "Electric Machinery." McGraw-Hill Science/Engineering/Math, 2003.

3. Sen, P.C. "Principles of Electric Machines and Power Electronics." John Wiley & Sons, 2013.

4. Nasar, S.A. and L.E. Unnewehr. "Electromechanics and Electric Machines." John Wiley & Sons, 1983.

5. Wildi, Theodore. "Electrical Machines, Drives and Power Systems." Pearson Education, 2005.

6. Chapman, Stephen J. "Electric Machinery and Power System Fundamentals." McGraw-Hill Education, 2002.