When searching for inverter duty induction motor authorized dealers, partnering with established Chinese manufacturers offers significant advantages in quality, cost-effectiveness, and technical innovation. These specialized motors, designed for variable-frequency drive applications, require precise engineering to withstand demanding industrial environments across the automotive, aerospace, HVAC, and energy sectors. Chinese manufacturers have evolved into global leaders, combining advanced manufacturing capabilities with competitive pricing structures that benefit industrial automation companies worldwide.

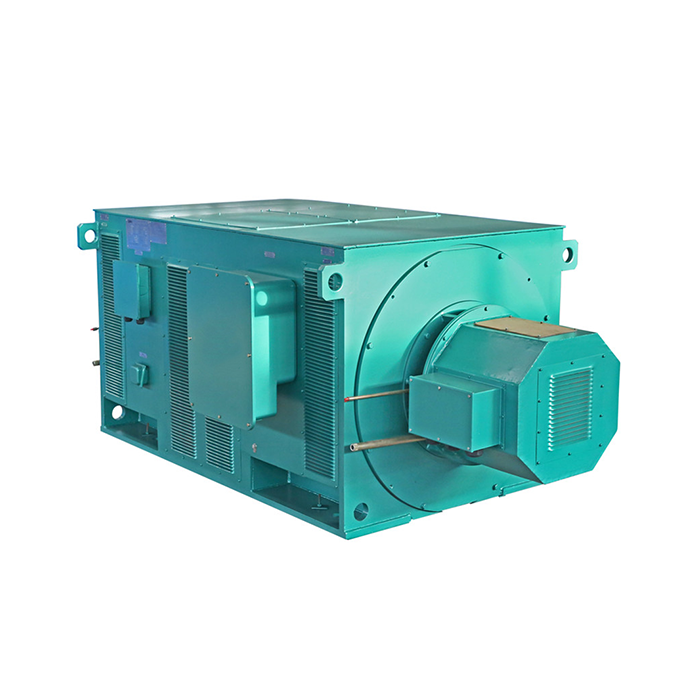

Series:YVFE3

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

China's Manufacturing Excellence in Inverter Duty Motor Production

Advanced Production Infrastructure

Chinese facilities use automated winding machines, precision die-casting, and vacuum pressure impregnation to ensure consistent quality and dimensional accuracy across large volumes for inverter duty induction motors applications.

Technical Innovation and R&D Capabilities

Dedicated R&D centers enhance insulation, cooling, and bearing protection, addressing variable speed challenges, thermal management, and electromagnetic interference for inverter duty induction motors.

Cost-Effective Manufacturing Scale

Efficient production, skilled workforce, and integrated supply chains enable competitive pricing from 0.75kW to 1000kW, making advanced inverter duty motors accessible for diverse industrial applications.

Essential Criteria for Selecting Reliable Manufacturers

Production Capacity Assessment

Evaluate manufacturers' capacity to reliably meet volume prerequisites. Offices with numerous generation lines guarantee supply versatility, diminished dangers, and versatility for differing applications, counting mechanical engines production.

Quality Management Systems

Inspect comprehensive quality control conventions, counting fabric review, get together confirmation, and last testing. Offices with reported frameworks and third-party reviews guarantee reliable item reliability.

Technical Support Capabilities

Assess progressing specialized help and customization administrations, counting direction on engine details, recurrence ranges, security, and integration with VFD systems.

Customer Service Infrastructure

Evaluate communication effectiveness, reaction times, and issue determination. Committed specialized client benefit groups improve collaboration over time zones and dialect barriers.

Financial Stability and Business Reputation

Review money related wellbeing, showcase notoriety, and client references. Steady producers give long-term unwavering quality, reliable benefit, and demonstrated execution in comparative mechanical applications.

Critical Certification Requirements for Industrial Applications

International Electrotechnical Commission Standards

Verify that engine plans comply with IEC measures for measurements, execution, and security necessities. These benchmarks guarantee compatibility with worldwide hardware and encourage worldwide arrangement over distinctive markets. Compliance illustrates the manufacturer's commitment to recognized designing hones and quality benchmarks.

ISO Quality Management Certification

ISO 9001:2015 certification demonstrates orderly quality administration forms all through the organization. This certification requires normal reviews and nonstop enhancement hones, giving certainty in reliable item quality and benefit conveyance. Audit certification scope and legitimacy to guarantee pertinence to engine fabricating operations.

Regional Market Compliance

Depending on your target markets, confirm fitting territorial certifications such as CE checking for European applications or UL postings for North American markets. These certifications illustrate compliance with particular security and execution necessities, encouraging advertise section and administrative endorsement processes.

Environmental and Safety Standards

Consider producers with RoHS compliance and natural administration certifications. These benchmarks reflect dependable fabricating hones and natural awareness, progressively vital for corporate maintainability activities and administrative compliance requirements.

Effective Sourcing Channels and Platform Strategies

Direct Manufacturer Engagement

Establish coordinate connections with producers to guarantee way better communication, estimating, and benefit quality. Coordinate engagement dispenses with middle person markups whereas giving get to to specialized skill and customization capabilities. Inquire about producer websites and contact specialized deals groups for point by point talks almost your particular requirements.

Trade Show Participation

Industry exchange appears give important openings to meet producers face-to-face, look at item tests, and examine specialized details. Major shows include driving producers exhibiting most recent advances and developments. These occasions encourage relationship building and empower comprehensive provider evaluation.

Professional Referrals and Industry Networks

Leverage industry contacts and proficient systems for producer suggestions. Colleagues with comparative applications can give important bits of knowledge almost provider execution, quality, and benefit levels. Industry affiliations regularly keep up provider catalogs and can encourage presentations to qualified manufacturers.

Online B2B Platforms

Established B2B stages interface buyers with confirmed producers, advertising introductory screening and communication assistance. Utilize these stages for preparatory investigation and starting contact, whereas conducting careful due diligence some sometimes then making last choice decisions.

Strategic Considerations for OEM and ODM Partnerships

Intellectual Property Protection

Establish agreements covering design ownership, confidentiality, and intellectual property rights. Document inverter duty induction motor specifications and performance criteria to prevent misunderstandings and protect proprietary designs throughout OEM and ODM collaborations.

Customization Capabilities

Evaluate manufacturer ability to modify standard designs, including winding configurations, bearings, and mounting. Assess engineering expertise and prior experience with similar inverter duty induction motor customization projects.

Development Timeline Management

Set realistic schedules for prototyping, testing, and production. Account for design iterations, approvals, and regular communication to address delays and ensure timeline adherence.

Long-term Partnership Planning

Consider capacity for ongoing collaboration, updates, technical support, and volume scaling. Establish performance metrics and service agreements to sustain quality and continuous improvement over time.

Effective MOQ and Pricing Negotiation Approaches

Understanding Minimum Order Requirements

Manufacturers set MOQs based on production efficiency, with standard products usually lower than customized solutions. Discuss flexibility, considering volume projections and potential long-term partnership opportunities.

Volume-Based Pricing Strategies

Negotiate tiered pricing rewarding larger orders and long-term commitments. Evaluate total costs including shipping, duties, and inventory, ensuring supply security and cost-effective procurement strategies.

Payment Terms and Financial Arrangements

Agree on terms balancing risk and cash flow, including letters of credit, milestones, and quality escrows. Address handling of quality issues, delays, and warranty claims.

Value-Added Services Integration

Include technical support, training, spare parts, and packaging customization. These services enhance supplier relationships and operational efficiency while reducing internal handling requirements.

Comprehensive Factory Audit and Quality Assurance Protocols

Production Facility Assessment

Conduct thorough evaluations of manufacturing facilities, including equipment condition, capacity utilization, and workflow organization. Examine material handling processes, storage conditions, and environmental controls. Assess the facility's ability to maintain consistent production quality and meet delivery commitments.

Quality Control System Verification

Review quality control procedures at each production stage, from incoming material inspection to final testing protocols. Examine test equipment calibration records, quality documentation systems, and corrective action processes. Verify statistical process control implementation and trending analysis capabilities.

Workforce Competency Evaluation

Assess workforce training programs, skill development initiatives, and retention rates. Skilled technicians and engineers directly impact product quality and consistency. Review training records, certification programs, and ongoing professional development activities.

Supplier Management Practices

Evaluate the manufacturer's approach to supplier selection, qualification, and ongoing management. Quality raw materials and components significantly impact final product performance. Review supplier audit programs, performance monitoring systems, and supply chain risk management practices.

Distinguishing Characteristics of Leading Suppliers

Digital Integration and Industry 4.0 Adoption

Leading manufacturers adopt IoT sensors, predictive maintenance, and data analytics for proactive quality control. Smart manufacturing capabilities support both industrial equipment production, enhancing process efficiency and consistency.

Sustainability and Environmental Responsibility

Suppliers implement energy-efficient processes, waste reduction, and responsible material sourcing, aligning with corporate sustainability goals and long-term cost efficiency.

Advanced Testing and Validation Capabilities

Top manufacturers invest in thermal, vibration, and electromagnetic testing to ensure reliability under demanding industrial conditions.

Global Service Network Development

International service networks provide local technical support, spare parts, and warranty services, improving responsiveness and reducing operational downtime for clients worldwide.

Conclusion

Selecting the right inverter duty induction motor manufacturer in China requires systematic evaluation of technical capabilities, quality systems, and service infrastructure. Successful partnerships depend on thorough due diligence, clear communication, and alignment of long-term objectives. The Chinese manufacturing sector offers compelling advantages in cost-effectiveness, technical innovation, and production scale, making it an attractive sourcing destination for industrial automation applications. Effective procurement prioritizes quality verification, certification compliance, and supplier assessment. Partnering with reliable manufacturers enhances product quality, reduces costs, and ensures technical support, improving operational efficiency and total cost of ownership.

Frequently Asked Questions

Q1: What distinguishes inverter duty motors from standard induction motors?

A: Inverter obligation engines highlight improved separator frameworks, fortified bearing security, and optimized cooling plans to handle variable recurrence drive operation. They withstand quick speeding up, deceleration, and temperature changes superior than standard engines, giving longer benefit life in VFD applications.

Q2: How can I verify a Chinese manufacturer's quality credentials?

A: Survey ISO certifications, conduct plant reviews, ask client references, and look at test reports. Confirm compliance with pertinent universal guidelines and survey quality control forms all through generation. Consider third-party assessment administrations for extra quality assurance.

Q3: What are typical lead times for custom inverter duty motor orders?

A: Standard items are regularly dispatch inside 2-4 weeks, whereas customized arrangements require 4-6 weeks depending on complexity. Components influencing lead time incorporate customization level, arrange amount, and current generation plans. Examine particular timeline prerequisites amid introductory negotiations.

Q4: How should I handle intellectual property protection when working with Chinese manufacturers?

A: Build up comprehensive non-disclosure assentions, record plan possession rights, and consider legitimate systems for IP security. Work with producers who illustrate regard for mental property rights and have built up approaches for securing client plans and specifications.

Partner with XCMOTOR for Superior Inverter Duty Motor Solutions

XCMOTOR stands ready to meet your industrial automation needs with premium inverter duty induction motor solutions engineered for exceptional performance and reliability. Our comprehensive product range covers power ratings from 0.75kW to 1000kW, featuring advanced thermal management systems, reinforced insulation, and superior bearing protection for demanding VFD applications. With ISO 9001:2015 certification and CE compliance, we ensure consistent quality while providing dedicated technical support for your specific requirements.

Our experienced engineering team collaborates with customers to optimize motor specifications for diverse industrial applications, from manufacturing automation to renewable energy systems. We maintain competitive pricing structures, flexible MOQ requirements, and rapid delivery capabilities to support your project timelines effectively. Contact us at xcmotors@163.com to discuss your inverter duty induction motor requirements and discover why leading companies choose XCMOTOR as their trusted supplier partner.

References

1. "Industrial Motor Market Analysis and Growth Projections 2024-2030" - International Energy Agency Industrial Equipment Division

2. "Variable Frequency Drive Applications in Industrial Automation" - Institute of Electrical and Electronics Engineers Motor Drive Systems Committee

3. "Quality Management Systems in Electric Motor Manufacturing" - International Organization for Standardization Technical Committee 2

4. "Inverter Duty Motor Design Guidelines and Best Practices" - National Electrical Manufacturers Association Motor and Generator Section

5. "Supply Chain Risk Management in Industrial Equipment Procurement" - American Production and Inventory Control Society Research Foundation

6. "Energy Efficiency Standards for Industrial Motor Applications" - International Electrotechnical Commission Technical Committee 2