Selecting a 2500 kW motor for your high-voltage AC generator represents a strategic decision that balances substantial power output with operational reliability. This motor rating delivers exceptional performance across demanding industrial applications while maintaining manageable maintenance requirements and energy consumption patterns. The 2500 kW configuration offers optimal torque characteristics and voltage compatibility, making it particularly suitable for power generation facilities, heavy manufacturing operations, and large-scale infrastructure projects that require consistent, high-capacity electrical output.

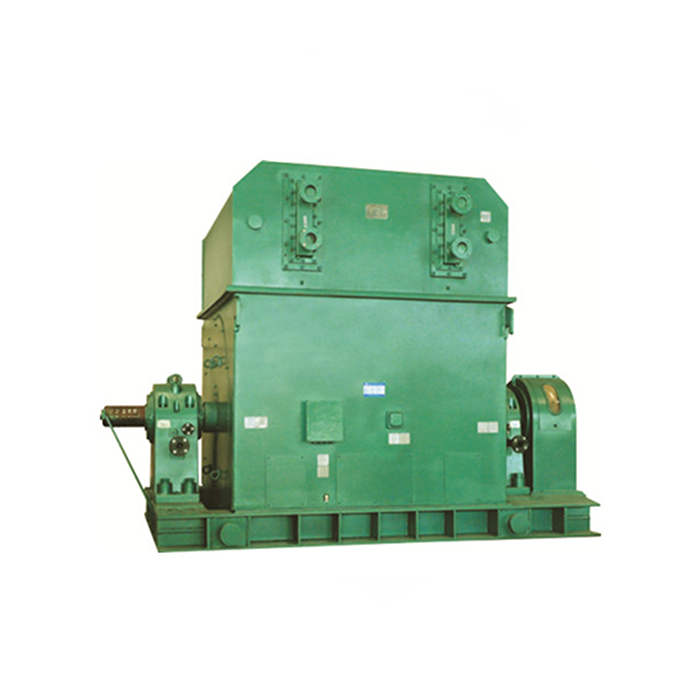

Series:YKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Technical Advantages of a 2500 kW Motor

The building brilliance behind high-capacity engines gets to be apparent when analyzing their center specialized determinations and operational capabilities. These engines coordinated progressed plan standards that address the complex requests of mechanical control generation.

Modern engine innovation joins advanced cooling frameworks that oversee warm loads successfully. The IC611 cooling strategy utilized in professional-grade engines guarantees ideal temperature control amid ceaseless operation. This cooling approach combines inner discuss circulation with outside warm scattering, keeping up component judgment indeed beneath supported high-load conditions.

Here are the fundamental technical advantages that distinguish these motors in industrial applications:

- Robust Construction Design: The durable cast frame provides exceptional structural integrity and superior heat dissipation capabilities. This construction method ensures the motor withstands harsh industrial environments while maintaining optimal performance levels throughout extended operational cycles.

- Advanced Rotor Technology: Precision-engineered rotor systems deliver smooth, vibration-free operation even when handling substantial mechanical loads. The balanced rotor design minimizes operational noise and extends component lifespan significantly.

- Superior Insulation Protection: Vacuum pressure impregnation techniques create robust electrical insulation that protects internal components from environmental factors and electrical stress, ensuring reliable performance in demanding conditions.

- Dynamic Balancing Systems: Meticulous balancing procedures eliminate operational vibrations, resulting in quieter performance and reduced mechanical wear on connected equipment and supporting structures.

These specialized developments translate specifically into decreased support costs and improved operational unwavering quality. The combination of progressed materials and accurate fabrication forms enables engines able of convey reliable execution over different mechanical segments, from control era to heavy fabricating applications.

Comparing 2500 kW Motors with Other Power Ratings

Understanding the performance characteristics and application suitability of different motor ratings helps engineers make informed equipment selection decisions. The mid-range positioning of this 2500 kw motor rating offers distinct advantages over both smaller and larger alternatives.

When assessing engine alternatives, the 2500 kW rating illustrates predominant flexibility compared to lower-capacity units whereas dodging the complexity and framework necessities related with bigger frameworks. This rating gives adequate control for significant mechanical applications without requiring broad office alterations or specialized taking care of equipment.

The voltage compatibility run traversing from 3000V to 11000V (±5%) obliges differing electrical framework arrangements commonly found in mechanical offices. This adaptability disposes of the require for broad electrical framework adjustments when coordination modern engine frameworks into existing operations.

Synchronous engine arrangements inside this control extend offer exact speed control and amazing control figure characteristics, making them perfect for applications requiring steady operational parameters. The capacity to keep up steady execution over shifting stack conditions guarantees solid generator operation in any case of request fluctuations.

Manufacturing measures compliance, counting JB/T 12730 and JB/T 12729 details, ensures steady quality and execution characteristics. These measures address basic perspectives of engine plan, development, and testing strategies that straightforwardly affect operational unwavering quality and safety.

Application Scenarios and Industry Use Cases

The flexibility of high-capacity engines amplifies over numerous mechanical divisions, each displaying one of a kind operational prerequisites and execution desires. Understanding these applications makes a difference recognize ideal engine setups for particular operational needs.

Power Generation and Core Infrastructure

Power generation facilities represent the primary application domain where these motors excel, such as a critical 2500 kw motor driving a boiler feed pump. Whether supporting coal-fired plants, natural gas facilities, or renewable energy installations, the consistent power output and reliable operation make them essential components in electrical generation systems. This sector demands uninterrupted performance, where motor durability directly impacts grid stability and operational continuity.

Demanding Manufacturing and Processing

Manufacturing and heavy process industries benefit significantly from the robust performance characteristics of these motors. Automotive and aerospace manufacturers depend on their precision for assembly and machining, while chemical plants and refineries rely on them for pumps and compressors that must operate continuously. A 2500 kw motor in these settings is often tasked with driving large-scale mixers or critical compressor trains, where failure can halt entire production lines, underscoring the need for extreme reliability.

Specialized Heavy-Duty Applications

The adaptability of these motor systems is further demonstrated in specialized heavy-duty sectors. In mining, they power extraction machinery under extreme loads, while water treatment facilities use them for high-volume pumping networks. Transportation infrastructure, including ports and railways, utilizes such motors for cargo handling and conveyance. In each case, customizing a 2500 kw motor with premium bearings and components ensures optimal performance in harsh conditions while maintaining essential serviceability and parts availability for minimal downtime.

Procurement Guidance for 2500 kW Motors

Successful engine acquisition requires cautious assessment of specialized determinations, provider capabilities, and long-term operational contemplations. The complexity of mechanical engine frameworks requires careful appraisal of numerous components beyond the introductory buy price.

Protection lesson evaluations essentially affect engine life span and support requirements. IP54 security gives satisfactory shielding against clean entrance and water spray, making it appropriate for most mechanical situations. This security level equates natural resistance with openness for scheduled upkeep procedures.

Voltage extend compatibility must be adjusted with the existing electrical foundation to avoid exorbitant framework adjustments. Engines planned to work over different voltage levels give establishment adaptability and future versatility as office necessities evolve.

Quality confirmation conventions during manufacturing directly impact long-term unwavering quality and execution consistency. Comprehensive testing methods that mimic real-world working conditions offer assistance distinguish potential issues some time recently hardware arrangement, decreasing the chance of unexpected failures and exorbitant downtime.

Delivery timelines and establishment bolster administrations play vital parts in extend planning and execution. Dependable providers give clear conveyance plans, comprehensive establishment documentation, and specialized bolster all through the commissioning process.

Conclusion

The selection of a 2500 kW motor for high-voltage AC generator applications represents a balanced approach to industrial power requirements. These motors deliver substantial power output while maintaining manageable operational and maintenance demands. The combination of advanced engineering, robust construction, and comprehensive support services ensures reliable performance across diverse industrial applications. When evaluating motor options, consider technical specifications, application requirements, and long-term operational costs to make informed procurement decisions that support sustained industrial productivity and operational excellence.

Frequently Asked Questions

Q1: What maintenance intervals are recommended for 2500 kW motors?

A: Standard support plans regularly incorporate month to month visual reviews, quarterly oil checks, and yearly comprehensive examinations. The particular support prerequisites depend on working conditions, obligation cycles, and natural components. Engines working in clean, controlled situations may amplify support interims, whereas those in cruel conditions require more visit attention.

Q2: How does the IP54 protection rating affect motor placement and installation?

A: IP54 security permits establishment in most mechanical situations where clean and moisture levels remain direct. This rating ensures against restricted tidy entrance and water shower from any direction, making it appropriate for indoor establishments and secured open air applications. Appropriate ventilation and waste containment remain critical for ideal performance.

Q3: What cooling requirements must be considered for continuous operation?

A: Nonstop operation requires satisfactory surrounding discuss circulation and temperature control inside the motor's indicated working extend. The IC611 cooling strategy gives successful warm dissemination, but establishment areas ought to guarantee unhindered discuss stream around the engine lodging. Natural temperatures ought to stay inside producer determinations to anticipate warm stress.

XCMOTOR - Your Trusted High-Performance Motor Solution Partner

XCMOTOR delivers industrial-grade motors with advanced engineering, rigorous testing, and reliable performance, supported by strong customer service for diverse power generation and manufacturing applications. As a dedicated 2500 kw motor supplier, we understand the critical importance of reliable power transmission in industrial operations. Our motor systems feature low noise and vibration characteristics that contribute to improved workplace environments while extending equipment lifespan through reduced mechanical stress.

Customers get comprehensive support beyond equipment delivery. To maximize motor performance throughout its lifecycle, we give clear installation instructions, maintenance advice, and fast technical help. Also, our diverse bearing replacement solutions fulfill customer and operational demands. Contact us at xcmotors@163.com to discuss your specific motor requirements and receive detailed technical specifications tailored to your application needs. Our experienced engineering team stands ready to provide comprehensive consultation services that help optimize your power generation systems.