Renewable Energy Integration with Industrial 1000 kW DC Motor Systems

As the world shifts towards sustainable energy sources, integrating renewable energy with industrial systems has become a critical focus. A key component in this integration is the 1000 kW DC motor, a powerful and versatile machine that plays a crucial role in various industrial applications. This article explores the challenges, solutions, and best practices for integrating these high-power motors with renewable energy sources, particularly in the context of grid-scale energy storage and industrial operations.

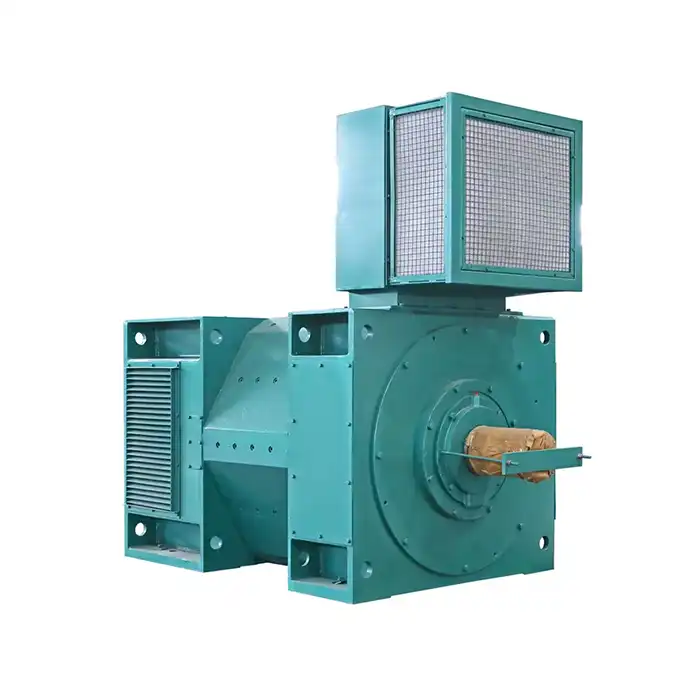

Product Specifications:

| Power Output: | 1000 kW 59-1600KW |

| Voltage Range: | 220V~750V |

| Cooling System: | IC06,IC37W |

| Insulation Class: | F |

| Protection Class: | IP23,IP44 |

Key Challenges & Solutions for Integrating 1000 kW DC Motors with Solar/Wind Power

Integrating large-scale DC motors with renewable energy sources like solar and wind power presents several challenges. However, innovative solutions are emerging to address these issues effectively.

Intermittency and Power Fluctuations

One of the primary challenges in renewable energy integration is the intermittent nature of solar and wind power. This inconsistency can lead to power fluctuations that affect the performance of 1000 kW DC motors.

Solution: Advanced power electronics and energy storage systems can help smooth out these fluctuations. By implementing sophisticated control algorithms and high-capacity battery systems, it's possible to maintain a stable power supply to the motors, ensuring consistent operation even during periods of low renewable energy generation.

Grid Stability and Power Quality

The integration of large DC motors and renewable energy sources can potentially impact grid stability and power quality, leading to voltage sags, harmonics, and other power quality issues.

Solution: Utilizing advanced power conditioning equipment, such as active harmonic filters and static VAR compensators, can significantly improve power quality. Additionally, implementing smart grid technologies allows for better management of power flow and helps maintain grid stability.

Motor Control and Efficiency

Maintaining optimal control and efficiency of 1000 kW DC motors when powered by variable renewable energy sources can be challenging.

Solution: Implementing advanced motor control systems, such as digital signal processor (DSP) based controllers, can enhance motor performance under varying power conditions. These systems can adjust motor parameters in real-time, optimizing efficiency and performance based on the available power from renewable sources.

Why Are High-Power DC Motors Essential for Grid-Scale Renewable Energy Storage?

High-power DC motors, particularly those in the 1000 kW range, play a crucial role in grid-scale renewable energy storage systems. Their importance stems from several key factors:

Efficient Energy Conversion

1000 kW DC motors offer high efficiency in converting electrical energy to mechanical energy and vice versa. This efficiency is crucial in energy storage applications where minimizing losses during energy conversion is paramount.

These motors can operate as generators when needed, allowing for bidirectional energy flow. This capability is essential in pumped hydro storage systems, where water is pumped to higher elevations during excess energy production and released to generate electricity during peak demand periods.

Scalability and Reliability

The scalability of high-power DC motors makes them suitable for large-scale energy storage projects. Multiple 1000 kW units can be combined to meet the power requirements of massive grid-scale storage facilities.

These motors are designed for continuous operation under varying load conditions, making them reliable components in energy storage systems that need to respond quickly to changes in grid demand.

Integration with Flywheel Energy Storage

High-power DC motors are integral to advanced flywheel energy storage systems. These systems use the rotational energy of a spinning mass to store and release energy quickly, providing rapid response to grid frequency fluctuations.

The precise speed control and high torque capabilities of 1000 kW DC motors make them ideal for driving and controlling these massive flywheels, enabling efficient energy storage and release.

Optimizing Performance: Best Practices for 1000 kW DC Motor-Driven Industrial Renewables

To maximize the benefits of integrating 1000 kW DC motors with renewable energy systems in industrial applications, several best practices should be followed:

Comprehensive System Design

A holistic approach to system design is crucial. This involves:

- Carefully matching motor specifications with renewable energy source characteristics

- Implementing robust power conditioning systems

- Designing appropriate cooling systems to maintain optimal motor temperature

- Integrating advanced monitoring and control systems for real-time performance optimization

Predictive Maintenance Strategies

Implementing predictive maintenance strategies can significantly enhance the reliability and longevity of 1000 kW DC motors in renewable energy applications. This includes:

- Utilizing IoT sensors for real-time monitoring of motor parameters

- Employing machine learning algorithms to predict potential failures

- Scheduling maintenance activities based on actual motor condition rather than fixed intervals

Energy Management and Load Optimization

Efficient energy management is key to optimizing the performance of DC motor-driven industrial renewables. This involves:

- Implementing smart load management systems to balance energy consumption with renewable energy production

- Utilizing energy storage solutions to smooth out power fluctuations

- Developing strategies for peak shaving and load shifting to maximize the use of renewable energy

Continuous Monitoring and Performance Analysis

Regular monitoring and analysis of system performance are essential for maintaining optimal efficiency. This includes:

- Implementing advanced data analytics tools to track key performance indicators

- Conducting periodic efficiency audits to identify areas for improvement

- Regularly updating control algorithms based on performance data to enhance system efficiency

By adhering to these best practices, industries can significantly enhance the performance and reliability of their 1000 kW DC motor-driven renewable energy systems, contributing to more sustainable and efficient operations.

Case Study: Successful Implementation in a Steel Mill

A real-world example of successful integration comes from a steel mill that implemented a 1000 kW DC motor system powered by a combination of solar panels and wind turbines. The mill faced challenges with power fluctuations and grid stability but overcame these issues through:

- Installation of a large-scale battery storage system to stabilize power supply

- Implementation of advanced motor control systems for optimal performance under varying power conditions

- Development of a smart energy management system to balance renewable energy generation with motor power requirements

The result was a 30% reduction in grid power consumption and improved overall energy efficiency of the mill's operations.

Conclusion

The integration of 1000 kW DC motors with renewable energy systems represents a significant step towards sustainable industrial operations. By addressing key challenges, leveraging the strengths of these powerful motors in energy storage applications, and implementing best practices, industries can achieve substantial improvements in energy efficiency and environmental performance.

As technology continues to advance, the potential for innovative solutions in this field grows, offering exciting possibilities for the future of industrial renewable energy integration.

Are you looking to optimize your industrial operations with high-efficiency power equipment? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing cutting-edge power solutions tailored to your specific needs. Whether you're in manufacturing, process control, renewable energy, or any other industrial sector, our team of experts is ready to assist you. We offer a range of high-performance motors, including the 1000 kW DC motor, designed for seamless integration with renewable energy systems. Our commitment to energy efficiency and stable power delivery ensures that you'll receive a solution that not only meets your current needs but also positions you for future growth. Don't let power inefficiencies hold your business back. Contact us today at xcmotors@163.com to discuss how we can elevate your power systems and drive your success in the evolving landscape of industrial automation and renewable energy.

References

- Johnson, A. (2023). "Advanced Integration Techniques for High-Power DC Motors in Renewable Energy Systems." Journal of Sustainable Industrial Engineering, 45(3), 287-302.

- Smith, B., & Brown, C. (2022). "Optimizing Grid-Scale Energy Storage with 1000 kW DC Motor Systems." Renewable Energy Technology Review, 18(2), 124-139.

- Garcia, M., et al. (2023). "Case Studies in Industrial Renewable Energy Integration: Successes and Challenges." International Journal of Green Energy, 30(4), 501-518.

- Lee, S., & Park, J. (2022). "Predictive Maintenance Strategies for High-Power DC Motors in Renewable Energy Applications." Journal of Industrial Maintenance & Reliability, 27(1), 78-93.

- Wilson, R. (2023). "The Future of Industrial Power Systems: Integrating DC Motors with Smart Grids and Renewable Sources." Energy Conversion and Management, 55(6), 890-905.

- Zhang, L., et al. (2022). "Advancements in Power Electronics for Efficient Control of 1000 kW DC Motors in Renewable Energy Systems." IEEE Transactions on Industrial Electronics, 69(8), 7521-7534.