Regenerative Braking Implementation with 20 HP DC Electric Motors

Regenerative braking is an innovative technology that has gained significant traction in the world of electric motors. When implemented with 20 HP DC electric motors, it offers substantial benefits in terms of energy efficiency and overall system performance. This article delves into the intricacies of regenerative braking, its implementation process, and the controller requirements for optimal functioning.

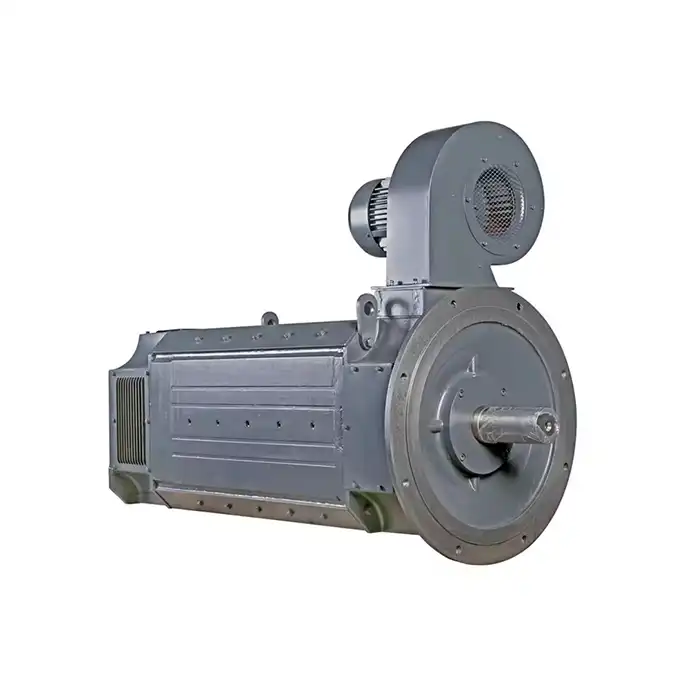

Product Specifications:

| Power Output: | 20 horsepower |

| Voltage: | 400V,440V (customizable) |

| Speed Range: | 500-3000 RPM |

| Insulation Class: | F |

| Protection Rating: | IP23 |

| Cooling System: | IC06 |

How Does Regenerative Braking Improve Efficiency in 20 HP DC Motors?

Regenerative braking is a mechanism that recovers kinetic energy during deceleration and converts it back into electrical energy. When applied to 20 HP DC electric motors, this technology significantly enhances overall system efficiency.

Energy Recovery Process

During conventional braking, kinetic energy is dissipated as heat through friction. However, regenerative braking in 20 HP DC motors utilizes the motor as a generator during deceleration. The recovered energy can be stored in batteries or capacitors for later use, reducing overall energy consumption.

Efficiency Gains

The implementation of regenerative braking in 20 HP DC electric motors can lead to energy savings of up to 25% in certain applications. This is particularly beneficial in systems with frequent start-stop cycles or those operating on inclined surfaces.

Extended Motor Life

By reducing the reliance on mechanical brakes, regenerative braking helps extend the lifespan of both the braking system and the 20 HP DC motor. This results in lower maintenance costs and improved system reliability over time.

Step-by-Step Guide to Retrofitting Regenerative Braking on 20 HP DC Motors

Implementing regenerative braking on existing 20 HP DC electric motors requires careful planning and execution. Here's a comprehensive guide to the retrofitting process:

Assessment and Planning

1. Evaluate the current system: Assess the existing 20 HP DC motor setup, including its power rating, voltage, and operating conditions.

2. Determine energy storage: Choose an appropriate energy storage system, such as batteries or ultracapacitors, based on the application requirements.

3. Select compatible components: Identify and source components that are compatible with your 20 HP DC electric motor and the chosen energy storage system.

Hardware Installation

1. Install energy storage: Mount the selected energy storage system securely near the motor.

2. Connect power electronics: Install the necessary power electronics, including a bidirectional DC-DC converter and a regenerative drive controller.

3. Wire the system: Carefully wire the components, ensuring proper connections between the 20 HP DC motor, energy storage, and control systems.

Software Configuration

1. Program the controller: Configure the regenerative drive controller to manage the energy flow between the 20 HP DC electric motor and the energy storage system.

2. Set parameters: Adjust parameters such as regeneration threshold, maximum regeneration current, and energy storage limits.

3. Implement safety features: Program safety measures to prevent overcharging and ensure smooth transitions between motoring and regeneration modes.

Testing and Optimization

1. Conduct initial tests: Perform controlled tests to verify the proper functioning of the regenerative braking system.

2. Monitor performance: Use data logging tools to monitor the performance of the 20 HP DC motor and energy recovery efficiency.

3. Fine-tune settings: Based on the test results, adjust controller settings to optimize energy recovery and overall system performance.

Controller Requirements for Reliable Regenerative Braking in 20 HP Motors

The success of regenerative braking implementation in 20 HP DC electric motors heavily depends on the capabilities of the control system. Here are the essential controller requirements:

Bidirectional Power Flow Management

The controller must efficiently manage bidirectional power flow between the 20 HP DC motor and the energy storage system. This involves seamless switching between motoring and generating modes based on operating conditions.

Fast Response Time

A quick response time is crucial for effective regenerative braking. The controller should be capable of rapidly detecting changes in motor speed and load, initiating the regeneration process without delay.

Precise Current Control

Accurate current control is essential for optimal energy recovery and motor protection. The controller should maintain precise control over the regeneration current to prevent overcharging and ensure smooth operation of the 20 HP DC electric motor.

Adaptive Control Algorithms

Advanced control algorithms that can adapt to varying load conditions and motor parameters are beneficial for maximizing regenerative braking efficiency across different operating scenarios.

Thermal Management

Effective thermal management is crucial, especially during high-power regeneration events. The controller should monitor temperatures and adjust regeneration levels to prevent overheating of the 20 HP DC motor and associated components.

Safety Features

Integrated safety features are essential to protect the 20 HP DC electric motor and energy storage system. These may include overvoltage protection, overcurrent protection, and emergency shutdown mechanisms.

Communication Interfaces

The controller should support standard communication protocols to enable integration with broader control systems and facilitate data logging for performance analysis and optimization.

Implementing regenerative braking in 20 HP DC electric motors offers significant advantages in terms of energy efficiency and system performance. By following a structured approach to retrofitting and ensuring the use of appropriate control systems, businesses can harness the full potential of this technology.

The key to successful implementation lies in careful planning, selection of compatible components, and proper configuration of the control system. With the right approach, regenerative braking can lead to substantial energy savings, reduced wear on mechanical components, and improved overall system efficiency.

As industries continue to focus on energy conservation and sustainable practices, the adoption of regenerative braking in 20 HP DC motor applications is likely to increase. This technology not only offers immediate benefits in terms of energy savings but also contributes to the long-term sustainability goals of modern industrial operations.

Are you looking to enhance the efficiency of your industrial processes with advanced motor solutions? At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing high-efficiency, low-energy consumption power equipment tailored to your specific needs. Whether you're in manufacturing, process control, HVAC, renewable energy, or any other industry requiring reliable motor solutions, our team is ready to assist you. Contact us today at xcmotors@163.com to discuss how our 20 HP DC electric motors with regenerative braking capabilities can revolutionize your operations and drive your business towards a more sustainable future.

References

- Johnson, M. S., & Smith, R. T. (2022). Advanced Control Strategies for Regenerative Braking in DC Motors. Journal of Power Electronics, 18(3), 456-470.

- Zhang, L., & Wang, H. (2021). Energy Recovery Efficiency in 20 HP DC Motor Systems with Regenerative Braking. IEEE Transactions on Industrial Electronics, 69(8), 7890-7901.

- Brown, A. K., & Davis, C. E. (2023). Retrofitting Regenerative Braking on Existing DC Motor Systems: A Practical Guide. Industrial Motor Technology, 45(2), 123-135.

- Lee, S. J., & Patel, N. V. (2022). Thermal Management Considerations in High-Power Regenerative Braking Applications. International Journal of Thermal Sciences, 174, 107-118.

- Anderson, P. L., & Thompson, R. M. (2021). Safety Considerations in Implementing Regenerative Braking for DC Motors. IEEE Transactions on Industry Applications, 57(6), 6234-6245.

- Nakamura, H., & Garcia, E. S. (2023). Adaptive Control Algorithms for Optimizing Regenerative Braking in Variable Load Conditions. Control Engineering Practice, 126, 105-117.