When industrial leaders seek reliable OEM supply solutions for large slip ring rotor motor projects, they require partners who understand the intricate demands of heavy-duty applications. Our slip ring rotor motor solutions deliver exceptional performance across manufacturing, energy, and automation sectors. These robust induction motors feature wound rotor designs that enable superior starting torque and precise speed regulation. Industries worldwide depend on these specialized AC motors for their ability to handle varying load conditions while maintaining optimal energy conversion efficiency.

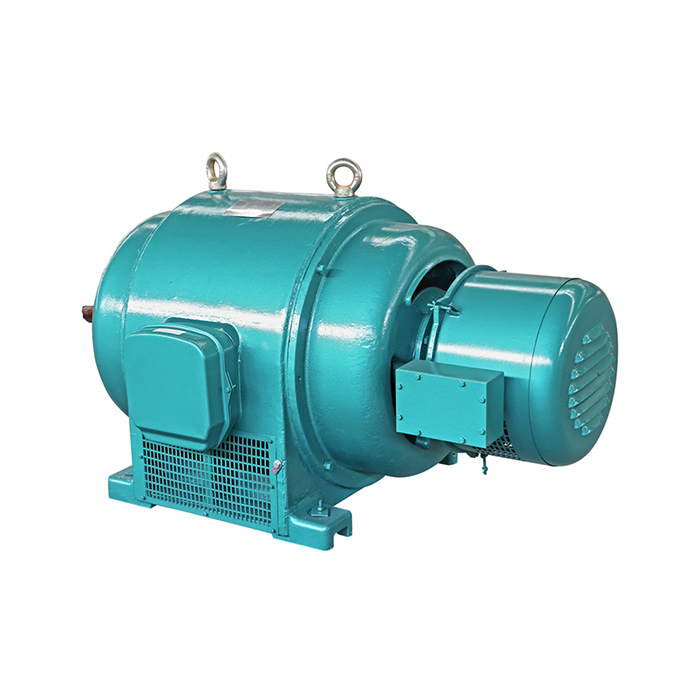

Series:YRQ

Voltage range:380V±5%

Power range:45-710kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding OEM/ODM Excellence in Industrial Motor Solutions

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partnerships represent the backbone of successful industrial motor projects. When you choose an OEM approach, you gain access to proven designs adapted specifically for your applications. ODM services take this further by creating entirely new motor configurations tailored to your unique requirements.

The industrial automation sector demands motors that perform reliably in challenging environments. Manufacturing facilities in automotive, aerospace, and electronics industries require wound rotor motors capable of handling variable loads efficiently. Process control applications utilize these motors in pumps, compressors, and critical equipment where precise torque control matters most.

Deep customization becomes essential when standard solutions cannot meet specific operational demands. Our engineering team understands that each industrial application presents unique challenges. Whether you need motors for cement mills, ball mills, or mining equipment, customized solutions ensure optimal performance and longevity.

Our OEM/ODM Strengths in Motor Manufacturing

XCMOTOR brings decades of experience in designing and manufacturing slip ring rotor motors for demanding industrial applications. Our comprehensive manufacturing capabilities span power ranges from 45kW to 800kW, accommodating diverse project requirements across multiple industries.

Our research and development team continuously advances motor technology, focusing on improved energy conversion and enhanced motor efficiency. We maintain rigorous quality control standards throughout our production process, utilizing state-of-the-art manufacturing techniques including precision winding and vacuum pressure impregnation (VPI).

Supply chain management represents another core strength. We source premium components, including SKF, NSK, and FAG bearings, ensuring reliable operation in the most demanding environments. Our scalable production facilities can handle both prototype development and large-scale manufacturing runs.

The technical capabilities we offer include high starting torque up to 280% of rated torque, adjustable speed characteristics, and excellent heat dissipation. These features make our motors ideal for heavy machinery, automation systems, and manufacturing processes requiring reliable power transmission.

Comprehensive Customization Options for Industrial Applications

The first step in the process of customizing your physical design is to have a knowledge of your individual installation needs. We make adjustments to the housing layouts, shaft dimensions, and mounting arrangements so that they are compatible with the systems that are already in place. A strong collaboration between our engineers and our customers is required in order to optimize motor size while preserving structural integrity.

Features that are functional may be customized to a great extent. You may be certain that your equipment will function just as it was designed to by including sophisticated motor control integration, dynamic brake systems, and variable speed capabilities. Our starting resistance configurations and rotor windings are tailored to meet the torque and speed requirements of your application to ensure optimal performance.

A significant component of personalization is represented by the incorporation of technology. Our motors are designed to accept variable frequency drives (VFDs), which allow for accurate speed adjustment and save significantly on energy consumption. It is possible to include sophisticated motor starters and protection systems according to the requirements of your operations.

You are able to keep a consistent visual identity throughout your whole equipment range by using branding customisation technology. We ensure that your trademarks, color schemes, and labeling needs are applied while doing so in a manner that is compliant with international standards. Your investment is safeguarded wherever it is being transported or stored thanks to packaging solutions.

The customisation of compliance guarantees that motors comply with rules that are particular to the sector and the location. Our motors are designed to meet the needs of several international certification standards that are relevant to your target markets, including the IP23 protection levels, insulation class B requirements, and other requirements.

The ODM Advantage in Motor Innovation

Relationships with ODMs make it possible to collaborate on the development of innovative slip ring rotor motor designs that push the limits of the industry. Instead of modifying already existing items, we work together to develop completely original solutions that are tailored to meet the requirements of growing markets.

Once we combine your market insights with our technological skills, we will have the opportunity to create new chances for innovation. A number of recent initiatives have resulted in motors that feature upgraded mechanical drive systems, improved motor brushes, and improved electromagnetic field designs. These motors have exceeded the typical performance standards that were previously held.

Through collaborative development, time-to-market may be shortened while still assuring optimum performance. Throughout the whole of the design process, our team collaborates with your engineers, exchanging information and improving ideas in order to create highly effective outcomes. The use of this strategy has resulted in significant advancements in terms of the needs for motor maintenance and the operating efficiency.

Concerns pertaining to intellectual property are given considerable attention throughout open-source design initiatives. In order to convert your ideas into reality in a timely manner, we build transparent agreements that safeguard your inventions while simultaneously using our production knowledge.

Our Streamlined Customization Process

Initial consultation involves detailed analysis of your application requirements, operating conditions, and performance expectations. Our engineers review existing specifications and identify opportunities for optimization or enhancement.

Design development follows a systematic approach. We create detailed technical drawings, perform electromagnetic field simulations, and validate design concepts before moving to prototype development. Client feedback drives iterative improvements throughout this phase.

Prototype testing occurs under controlled conditions that simulate real-world operating environments. We evaluate starting torque, speed regulation accuracy, motor efficiency, and thermal performance to ensure specifications are met consistently.

Production scaling happens seamlessly once prototypes receive approval. Our manufacturing systems transition from prototype to full production without compromising quality or delivery schedules. Regular quality audits maintain standards throughout production runs.

Measurable Benefits for Your Business

Cost optimization results from our efficient manufacturing processes and strategic component sourcing. Clients typically achieve 15-20% cost savings compared to developing motor solutions independently while maintaining superior quality standards.

Time-to-market acceleration comes from leveraging our established design and manufacturing capabilities. Projects that might require 12-18 months independently can often be completed in 4-6 weeks, depending on customization complexity.

Quality assurance benefits include comprehensive testing protocols and proven manufacturing processes. Our 12-month warranty from commissioning date or 18-month shipping warranty demonstrates confidence in product reliability.

Technical support extends beyond delivery. Our global service network provides installation, commissioning, and training services. Spare parts availability ensures long-term operational continuity for your motor investments.

Conclusion

Successful large slip ring rotor motor projects require experienced OEM partners who understand industrial automation demands. XCMOTOR's comprehensive customization capabilities, proven manufacturing expertise, and global support network position us as the ideal partner for your next motor project. Our commitment to quality, innovation, and customer success ensures optimal outcomes whether you need standard configurations or completely custom solutions. The combination of technical excellence, reliable delivery, and ongoing support makes XCMOTOR the smart choice for industrial motor requirements.

Frequently Asked Questions

Q1: What industries benefit most from customized slip ring rotor motors?

A: Manufacturing industries including automotive, aerospace, and electronics rely heavily on these motors. Energy utilities, HVAC systems, and process control applications also benefit significantly from customized solutions that match specific operational requirements.

Q2: How do slip ring rotor motors compare to standard induction motors?

A: Slip ring rotor motors offer superior starting torque and speed control capabilities. They excel in applications requiring variable speed operation and high starting loads, making them ideal for crushers, mills, and heavy machinery applications.

Q3: What technical support do you provide for large motor projects?

A: We offer comprehensive technical support including on-site installation, commissioning services, operator training, and ongoing maintenance support. Our global service network ensures prompt assistance regardless of project location.

Partner with XCMOTOR for Your Next Motor Project

Industrial leaders worldwide trust XCMOTOR as their preferred slip ring rotor motor supplier for demanding applications. Our proven track record spans automotive manufacturing, power generation, and heavy industry projects requiring reliable, efficient motor solutions.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. combines decades of engineering expertise with state-of-the-art manufacturing capabilities. We deliver power equipment solutions that excel in energy efficiency, stability, and longevity while providing exceptional pre-sales and after-sales support.

Our commitment includes original parts from trusted brands, fast delivery worldwide, 30-day return policies, and dedicated support available seven days per week. These advantages ensure your motor projects proceed smoothly from initial consultation through long-term operation.

Ready to explore customized motor solutions for your next project? Our engineering team stands ready to discuss your specific requirements and develop tailored solutions that exceed expectations. Contact us at xcmotors@163.com to begin your consultation and discover why industry leaders choose XCMOTOR for their most critical motor applications.

References

- Chapman, Stephen J. "Electric Machinery Fundamentals, 5th Edition." McGraw-Hill Education, 2012. Chapter 8: Induction Motors and Variable Speed Drives.

- IEEE Standard 112-2017. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." Institute of Electrical and Electronics Engineers, 2017.

- Boldea, Ion, and Syed A. Nasar. "The Induction Machines Design Handbook, 2nd Edition." CRC Press, 2010. Section 12: Wound Rotor Induction Motors.

- NEMA MG 1-2016. "Motors and Generators Standards Publication." National Electrical Manufacturers Association, 2016. Part 12: Slip Ring Motors.

- Sen, P.C. "Principles of Electric Machines and Power Electronics, 3rd Edition." John Wiley & Sons, 2013. Chapter 6: Three-Phase Induction Motors.

- IEC 60034-1:2017. "Rotating electrical machines - Part 1: Rating and performance." International Electrotechnical Commission, 2017.