When choosing the right 4000 kW motor for generator systems, you need to carefully look at performance specs, operational needs, and variables that affect long-term dependability. These powerful motors are very important in power plants, factories, and other industrial settings where constant performance has a direct effect on production. Knowing about voltage compatibility, protective ratings, and application-specific needs makes ensuring that systems work well together and run well in a wide range of industrial settings.

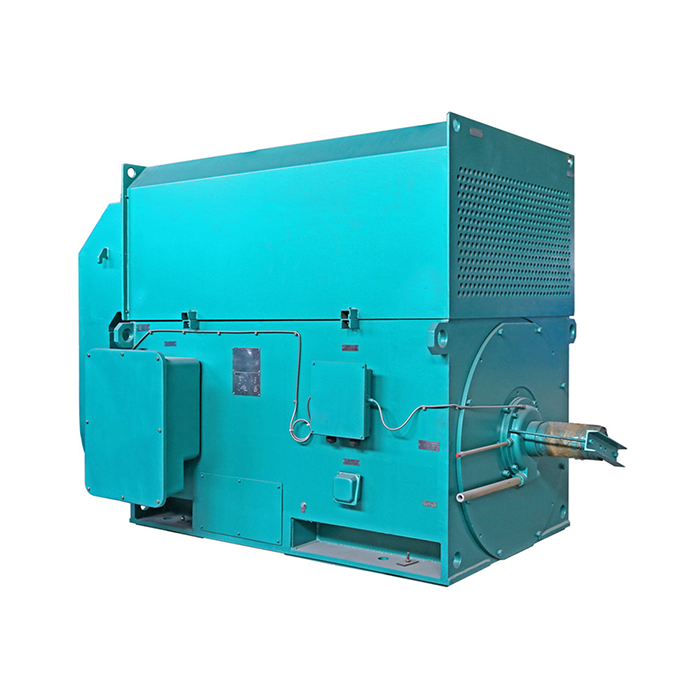

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Learning the Basics of 4000 kW Motors

High-capacity motors in the 4000 kW series are advanced technical solutions suited for tough industrial uses. These motors usually work with voltages between 3000V and 11000V, and they have very strict tolerance levels of ±5% to make sure they work well in all kinds of grid circumstances.

There are a few important things that make up the basic design of these motors. The operating speeds vary from 500 to 3000 RPM, which makes them suitable for a wide variety of uses, from heavy-duty crushers to high-speed compressors. The IP54 protection grade keeps dust and water from getting in, so these motors may be used in tough industrial settings.

These strong motors are used in a lot of important places, such water pumps in cities, big compressors in factories, crushers in mines, and cutting machine tools in heavy industries. These motors may also be used in transportation machines, where dependability and regular power supply are still highly important.

The construction includes tough cast iron frames that make it very strong and durable, even in tough working situations. Precision-balanced rotors make sure that the system runs smoothly with no vibration, which improves overall performance and reduces wear and tear on the parts during long periods of use.

Evaluating 4000 kW Motor Performance

Performance evaluation requires comprehensive analysis of multiple operational metrics that directly impact both immediate functionality and long-term operational costs. Starting characteristics play a crucial role, with typical starting currents ranging from 5-7 times the rated current and starting torque delivering 60-80% of rated torque capacity.

Here are the core performance advantages of 4000 kW motors:

- High Energy Efficiency Design: Advanced winding techniques and precision manufacturing processes maximize energy conversion while minimizing losses, resulting in reduced operational costs and improved environmental sustainability across industrial applications.

- Low Noise Operation: Engineered noise levels below 85 dB(A) ensure compliance with workplace safety standards while maintaining comfortable working environments in industrial facilities.

- Minimal Vibration: Precision-balanced rotor assemblies and high-quality bearings significantly reduce mechanical vibration, extending equipment lifespan and reducing maintenance requirements.

- Extended Service Life: Robust construction materials and advanced cooling systems contribute to extended operational periods between major maintenance intervals.

These performance characteristics effectively address critical production challenges including energy consumption optimization, workplace noise management, and equipment reliability requirements. The integration of PT100 temperature sensors in stator windings and bearings provides real-time thermal monitoring, preventing overheating conditions that could compromise motor integrity.

Selecting the Best 4000 kW Motor for Your Needs

When selecting a motor, it is necessary to do a thorough analysis of the operating needs, environmental circumstances, and long-term performance expectations.

- Maintaining compliance with industry standards, such as JB/T 12730 and JB/T 12729, guarantees both dependability and interoperability with pre-existing industrial systems.

- When it comes to long-term dependability and maintenance needs, bearing selection is a crucial decision point that must be taken into consideration. Standard dependability is provided by anti-friction bearings, while choices for SKF, NSK, and FAG bearings give additional performance characteristics depending on the needs of a particular application and the preferences of the client.

- Choosing an insulation class between F and H ratings is contingent on the temperature needs of the operation as well as the circumstances of the surrounding environment. Class F insulation can withstand temperatures up to 155 degrees Celsius, while Class H insulation can withstand temperatures up to 180 degrees Celsius in more challenging thermal settings.

- The most advanced cooling systems are able to keep operating temperatures at acceptable levels even when faced with difficult situations. The advanced thermal management system prevents the system from overheating while also guaranteeing that it maintains a constant performance regardless of the load circumstances or the ambient temperature.

Maintenance and Longevity of 4000 kW Motors

Strategies for preventative maintenance have a considerable influence on the lifetime of 4000 kW motors and the dependability of their operations.

- Assessment of the bearing condition, verification of the thermal monitoring system, and evaluation of the functioning of the cooling system should all be included in the routine inspection schedules.

- An important factor that contributes significantly to long-term dependability is the manufacturing process. The precision die-casting of components guarantees both the structural integrity and the dimensional correctness of the components.

- It is possible to achieve higher insulation performance by combining advanced winding methods with vacuum pressure impregnation (VPI), which allows the insulation to endure operating stresses for prolonged periods of time.

- When rotor assemblies are dynamically balanced throughout the manufacturing process, vibration sources that might result in premature bearing wear or structural fatigue are eliminated.

- A comprehensive testing and quality control approach is used to validate performance characteristics prior to delivery. This ensures that motors satisfy the specifications that have been established on the installation side.

- Chores such as monitoring the lubrication system, inspecting the electrical connections, and cleaning the cooling system are examples of routine maintenance chores. Calibration of temperature sensors and evaluation of bearing condition should be carried out in accordance with the guidelines provided by the manufacturer in order to ensure that the motor continues to function at its highest level throughout its entire operating life.

XCMOTOR: Leading Provider of 4000 kW Motors

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. operates as XCMOTOR, delivering comprehensive power equipment solutions tailored to industrial requirements. Our commitment centers on providing high-energy motors with exceptional performance characteristics, low energy consumption, and stable power delivery across demanding applications.

Our product portfolio encompasses motors ranging from 200 to 3150 kW capacity, accommodating diverse industrial requirements from compact installations to large-scale power generation facilities. The comprehensive voltage range spanning 3000V to 11000V ensures compatibility with various electrical infrastructure configurations.

Quality assurance begins with component selection, utilizing only parts from trusted brands to ensure reliability and longevity. Our fast delivery service includes complimentary shipping for all products, reducing project timelines and installation costs. The 30-day return policy provides confidence in product selection, while dedicated support extends through weekends to address urgent operational requirements.

Technical expertise encompasses application engineering, installation guidance, and ongoing support throughout the motor's operational life. Our team addresses pre-sales consultations, technical specifications, and post-installation performance optimization to ensure customer satisfaction and operational success.

Conclusion

Selecting the optimal 4000 kW motor requires comprehensive evaluation of technical specifications, operational requirements, and long-term performance expectations. Understanding voltage compatibility, protection ratings, and application-specific features ensures successful system integration and reliable operation. XCMOTOR's commitment to quality, comprehensive support services, and proven track record in power equipment solutions makes us the ideal partner for your high-capacity motor requirements. Our expertise in industrial applications combined with superior product quality delivers the reliability and performance your operations demand.

Frequently Asked Questions

Q1: What voltage ranges are available for 4000 kW motors?

A: Our 4000 kW motors accommodate voltage ranges including 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%, and 11000V±5%. This comprehensive range ensures compatibility with various electrical infrastructure configurations across different industrial applications and regional power standards.

Q2: How do I determine the appropriate protection rating for my application?

A: The IP54 protection rating provides adequate defense against dust ingress and water splashing, suitable for most industrial environments. Consider environmental factors including moisture levels, dust concentration, and cleaning requirements when evaluating protection needs for your specific application.

Q3: What maintenance intervals are recommended for optimal performance?

A: Maintenance schedules depend on operational conditions and load factors. Generally, bearing lubrication should occur every 2000-4000 operating hours, while comprehensive inspections including thermal sensor calibration and electrical connection assessment should occur annually or per manufacturer specifications.

Partner with XCMOTOR for Your High-Capacity Motor Requirements

XCMOTOR stands as your reliable 4000 kW motor manufacturer, combining decades of engineering expertise with commitment to customer satisfaction. Our motors feature easy installation procedures, simplified maintenance requirements, and extended service life that reduces total cost of ownership across industrial applications.

Our comprehensive support includes technical consultation, application engineering, and post-installation optimization services. Whether you require motors for power generation facilities, manufacturing operations, or specialized industrial applications, our team provides customized solutions that meet precise operational requirements.

Ready to enhance your generator system performance with premium-quality motors? Our specialists stand ready to discuss your specific requirements and provide detailed technical recommendations. Contact us at xcmotors@163.com for immediate assistance to explore our 4000 kW motor product portfolio and technical specifications.