When you need reliable high power motor solutions for demanding industrial operations, our OEM 4000 kW motors deliver exceptional performance across diverse applications. These industrial motors provide the robust power output essential for heavy-duty manufacturing, power generation, and process control systems. Our electric motor designs incorporate advanced engineering principles that ensure optimal motor efficiency while maintaining dependable operation in challenging environments. Whether you're powering large compressors, driving massive pumps, or operating critical manufacturing equipment, these motors offer the customization flexibility that modern industries demand.

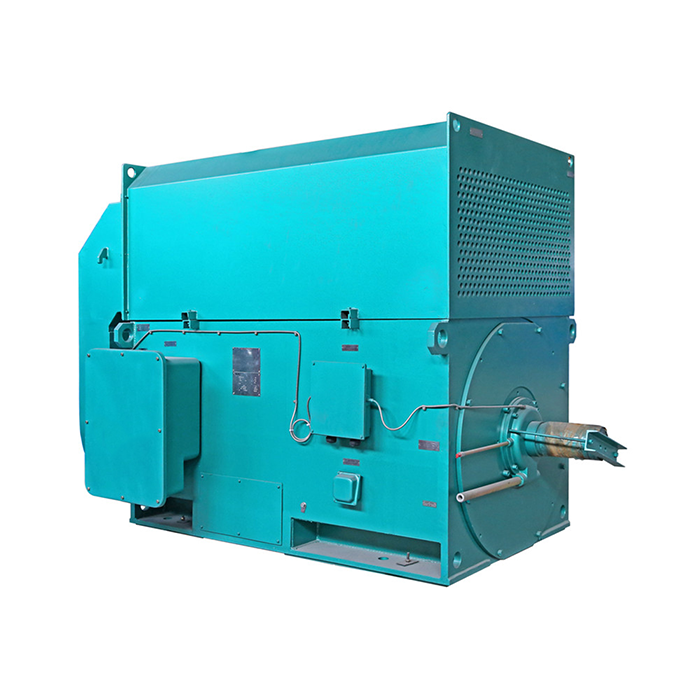

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding OEM/ODM Manufacturing for High-Power Electric Motors

OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) represent two distinct approaches to motor manufacturing that address different market needs. OEM manufacturing involves producing motors according to your exact specifications and designs, while ODM services include complete design development alongside manufacturing capabilities.

Deep customization matters significantly in the high power motor industry because standard solutions rarely meet the precise requirements of specialized applications. Each industrial setting presents unique challenges regarding motor torque requirements, environmental conditions, and operational parameters. Manufacturing facilities in automotive production lines require different motor characteristics compared to water treatment plants or mining operations.

The complexity of modern industrial automation demands motors that integrate seamlessly with existing systems while providing reliable performance under varying load conditions. Custom motor solutions, like 4000 kW motors, enable precise matching of power rating, speed control requirements, and protection specifications to your operational needs.

Our OEM/ODM Strengths in High-Power Motor Manufacturing

We have experience developing and producing industrial motors from 200-3150 kW for high-voltage applications from 3.3 kV to 11 kV systems. Our manufacturing skills include motor design, precise component manufacture, and strict quality control.

Our research and development team develops motor efficiency solutions including cooling systems and motor winding. Dynamic balancing and thermal protection integration are part of our quality control measures throughout manufacturing.

Supply chain management is a strength, with partnerships allowing variable bearing selection from SKF, NSK, and FAG depending on your needs. Our scalable production facilities support prototype and mass production.

The facility follows JB/T 12730 and 12729 standards to ensure quality throughout all manufacturing batches. Advanced testing equipment checks motor performance before delivery.

Manufacturing Excellence

Our precision die-casting processes create robust cast iron frames that withstand demanding operational environments. Vacuum pressure impregnation (VPI) techniques enhance motor insulation integrity, extending service life while reducing maintenance requirements.

Dynamic balancing procedures minimize motor vibration levels, contributing to smoother operation and reduced wear on connected equipment. Each motor undergoes comprehensive testing protocols that verify performance specifications before shipment.

Comprehensive Customization Options for Industrial Applications

Physical design customization includes frame, mounting, and environmental protection ratings. We meet dimensions requirements while retaining structural integrity and thermal management.

Variable frequency drive compatibility, motor control integration, and bespoke motor starter may be customized for your operations. Whether you require strong starting torque for crushers or smooth acceleration for precise manufacturing equipment, torque profiles may be customized.

Technology integration includes improved cooling, temperature monitoring, and protective systems. Place PT100 temperature sensors strategically throughout motor windings and bearing assemblies to monitor thermal conditions.

Motor look, nameplate specs, color schemes, and identifying systems may be customized with branding. We meet regional electrical standards and certification criteria throughout markets. Packaging protects motors during delivery and meets handling standards.

Voltage and Power Customization

Our voltage range flexibility spans 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%, and 11000V±5%, enabling integration with diverse electrical systems. Power output customization within our 200-3150 kW range allows precise matching to your load requirements.

Motor speed control options accommodate applications requiring variable speed operation or fixed-speed performance. Energy consumption optimization reduces operational costs while maintaining required performance levels.

The ODM Advantage in Motor Development

ODM services enable collaborative development of entirely new motor solutions tailored to emerging application requirements. This approach proves particularly valuable when existing motor designs cannot adequately address specific operational challenges.

Co-developing new 4000 kw motor solutions involves comprehensive analysis of your application requirements, environmental conditions, and performance expectations. Our engineering team works closely with your technical staff to identify optimal motor design parameters.

The development process includes detailed motor load analysis, thermal modeling, and vibration studies to ensure optimal performance characteristics. Prototype development and testing validate design concepts before committing to production tooling.

Innovation opportunities emerge through ODM partnerships, potentially creating competitive advantages through proprietary motor designs. Intellectual property arrangements protect your investment in custom motor development while ensuring manufacturing exclusivity.

Collaborative Design Process

Initial consultation identifies specific application requirements and operational constraints. Our technical team evaluates existing system parameters and proposes motor design modifications that optimize overall system performance.

Design iteration involves multiple review cycles, incorporating feedback from your engineering team and operational staff. This collaborative approach ensures final motor designs meet both technical specifications and practical implementation requirements.

Our Customization Process

The customizing process starts with application study of your power needs, ambient circumstances, and integration limits. Application-specific motor characteristics are determined via technical consultation.

Design development optimizes motor performance using your requirements and our technical experience. We give technical drawings and specifications for evaluation before manufacture.

Prototypes provide controlled performance testing. Motor efficiency, noise, vibration, and thermal performance are tested against requirements.

Manufacturing is efficient and quality is maintained using production planning. Progress updates keep you informed throughout manufacture.

Quality assurance involves testing motors, confirming performance characteristics, and checking specifications. Delivery coordination guarantees motors arrive on schedule for your project.

Timeline and Communication

Project timelines vary based on customization complexity, typically ranging from initial consultation through delivery. Regular communication maintains project visibility and enables prompt resolution of any technical questions.

Documentation packages include detailed technical specifications, installation guidelines, and maintenance recommendations specific to your custom motor design.

Benefits to You

Custom motor solutions provide precise performance matching to your operational requirements, eliminating compromise associated with standard motor selections. Optimized motor design reduces energy consumption while enhancing reliability and extending service life.

Competitive advantages emerge through proprietary motor designs that address specific application challenges more effectively than generic solutions. Manufacturing partnerships ensure consistent supply availability and technical support throughout motor service life.

Cost optimization occurs through efficient motor design that reduces installation complexity and ongoing maintenance requirements. Long-term partnerships provide access to ongoing technical support and future design improvements.

Quality assurance through our established manufacturing processes ensures consistent performance across multiple motor units. Compliance with international standards facilitates global deployment of your equipment.

Long-term Value

Reduced operational costs result from optimized motor efficiency and extended service intervals. Technical support availability ensures prompt resolution of any operational questions or maintenance requirements.

Future scalability enables increased production volumes as your business grows, leveraging established motor designs and manufacturing processes.

Conclusion

Custom 4000 kW motor solutions represent a strategic investment in operational excellence, providing precisely matched performance characteristics that standard motors cannot deliver. Our OEM/ODM capabilities enable complete customization of motor design, from basic specifications to advanced features that address unique application challenges.

The combination of advanced manufacturing processes, comprehensive customization options, and dedicated technical support creates lasting value for your operations. Whether you need immediate motor solutions or long-term development partnerships, our expertise ensures optimal results that enhance productivity while reducing operational costs.

Your success depends on reliable, efficient motor performance that meets exact operational requirements. Partner with us to discover how custom motor solutions can transform your industrial operations and provide competitive advantages in your market.

Frequently Asked Questions

Q1: What voltage ranges can be accommodated in custom 4000 kW motor designs?

A: Our custom motors accommodate voltage ranges from 3000V±5% up to 11000V±5%, including standard configurations at 3300V, 6000V, 6600V, and 10000V. Each motor can be designed to match your specific electrical system requirements while maintaining optimal performance characteristics.

Q2: How long does the custom motor development process typically take?

A: Development timelines vary based on customization complexity, ranging from 8-16 weeks for standard modifications to 20-24 weeks for completely new designs. We provide detailed project schedules during initial consultation and maintain regular communication throughout the development process.

Q3: What quality standards and certifications do your motors meet?

A: All motors comply with JB/T 12730 and JB/T 12729 standards, with additional certifications available based on your regional requirements. Our quality control processes include comprehensive testing protocols that verify performance specifications before delivery.

Partner with XCMOTOR for Your Custom 4000 kW Motor Solutions

Ready to explore how our OEM/ODM capabilities can address your specific high power motor requirements? XCMOTOR combines advanced manufacturing expertise with comprehensive customization options to deliver motor solutions that exceed performance expectations.

Our experienced engineering team stands ready to analyze your application requirements and propose optimal motor designs. Whether you need a reliable 4000 kw motor supplier for ongoing projects or custom motor development for specialized applications, we provide the technical expertise and manufacturing capabilities you need.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. delivers original parts from trusted brands, fast delivery services, and dedicated support including weekend availability. Our 30-day return policy demonstrates confidence in motor quality and performance. Don't settle for standard solutions when custom motor design can optimize your operational performance. Our team eagerly awaits the opportunity to discuss your specific requirements and demonstrate how our customization capabilities create competitive advantages for your business.

Take the next step toward optimal motor performance by reaching out to our technical team. We're committed to providing power equipment solutions with high energy efficiency, low energy consumption, and stable power delivery. Contact us at xcmotors@163.com to begin your custom motor development project today.

References

- Industrial Motor Systems Energy Efficiency Guidelines, International Electrotechnical Commission Technical Report 60034-30, 2021 Edition

- High Voltage Motor Design and Application Principles, IEEE Standard 841-2021: Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled Motors

- Electric Motor Efficiency Standards in Industrial Applications, NEMA Standards Publication MG 1-2021: Motors and Generators

- Custom Motor Manufacturing Best Practices, International Organization for Standardization, ISO 12100:2020 Safety of Machinery Guidelines

- Power Generation Equipment Motor Requirements, American National Standards Institute, ANSI C50.41-2021: Polyphase Induction Motors for Power Generating Stations

- Industrial Automation Motor Control Systems, IEC 61800 Series: Adjustable Speed Electrical Power Drive Systems Standards, 2021 Consolidated Edition