In mechanical settings where combustible gases, vapors, or combustible cleaning agents are present, security remains a basic need. YBX5 explosion-proof motors play a crucial part in ensuring offices and faculty by successfully separating potential ignition sources produced amid engine operation. Outlined to contain sparkles, curves, and over the top warm, these engines essentially decrease the chance of fire or blast in perilous areas. This article looks at how ybx5 explosion-proof motors improve working environment security, back administrative compliance, and give dependable execution in demanding situations where standard electrical gear would pose unsatisfactory risks.

How YBX5 Explosion-Proof Motors Enhance Workplace Safety?

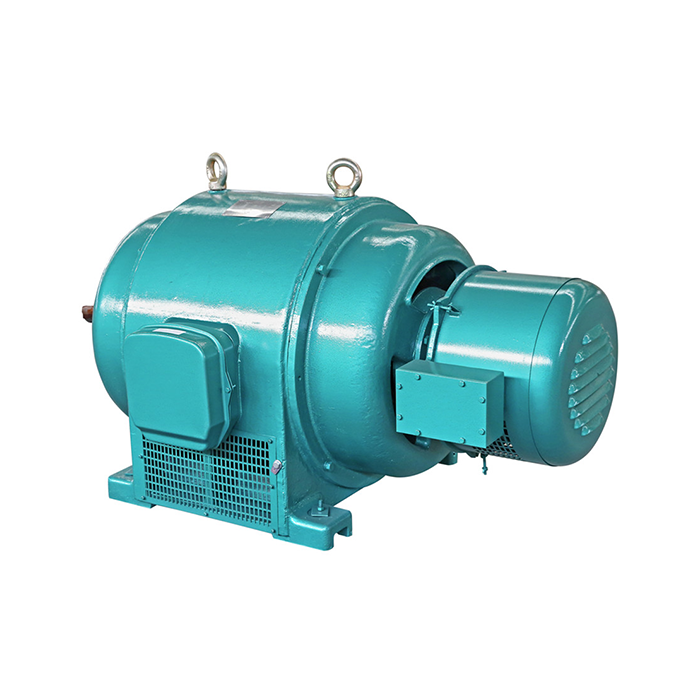

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What Are the Primary Ignition Sources in Industrial Settings and How Are They Contained?

Industrial situations frequently harbor different potential start sources that can lead to disastrous blasts if not legitimately overseen. Understanding these sources is pivotal for actualizing compelling security measures.

Electrical Sparks and Arcs

One of the most common ignition sources in industrial settings is electrical sparks and arcs. These can occur due to faulty wiring, loose connections, or equipment malfunction. YBX5 explosion-proof motors are designed to contain any internal sparks or arcs, preventing them from igniting the surrounding atmosphere.

Hot Surfaces

Equipment and apparatus can produce noteworthy warm amid operation, making hot surfaces that may light combustible substances. Explosion-proof engines like the YBX5 arrangement are developed with materials and plans that restrain surface temperatures, decreasing the chance of ignition.

Static Electricity

The buildup and release of inactive power can make flashes able of touching off combustible environments. YBX5 engines join establishing highlights and utilize materials that minimize inactive buildup, tending to this potential start source.

Mechanical Friction

Moving parts in industrial equipment can generate heat through friction, potentially creating an ignition source. The design of YBX5 explosion-proof motors includes features to minimize friction and contain any heat generated within safe limits.

The Role of Flameproof Enclosures and Pressure Relief Joints in Preventing Explosions

Flameproof enclosures and pressure relief joints are critical components in the design of YBX5 explosion-proof motors, working together to prevent the propagation of explosions and protect the surrounding environment.

Flameproof Enclosures: The First Line of Defense

Flameproof walled in areas serve as the essential boundary against blast engendering. These vigorous lodgings are planned to withstand inner blasts and avoid the transmission of flames or hot gases to the outside atmosphere.

Construction and Materials

YBX5 engine walls in areas are ordinarily developed from high-strength materials such as cast press or steel amalgams. These materials are chosen for their capacity to stand up to tall weights and temperatures related with inside explosions.

Flame Path Design

The walled-in areas highlight carefully designed fire ways – the holes and joints between diverse parts of the engine lodging. These ways are outlined to cool and extinguish any hot gasses getting away from an inner blast, anticipating them from touching off the outside atmosphere.

Pressure Relief Joints: Managing Internal Pressures

While flameproof walled in areas contain blasts, weight help joints play a significant part in overseeing the inside weights that construct up amid an blast event.

Controlled Venting

Pressure help joints are outlined to permit for controlled venting of blast weights. This anticipates the buildup of over the top inside weight that may possibly burst the engine enclosure.

Rapid Cooling Effect

As gasses pass through the weight alleviation joints, they experience fast extension and cooling. This handle assist diminishes the temperature of getting away gasses, minimizing the chance of outside ignition.

Synergy Between Enclosures and Relief Joints

The combination of flameproof walled in areas and weight help joints in YBX5 engines makes a comprehensive blast security framework. This collaboration guarantees that indeed if an inside blast happens, it remains contained and does not proliferate to the encompassing dangerous atmosphere.

Contributing to Overall Plant Safety Compliance and Risk Mitigation Strategies

Implementing YBX5 explosion-proof motors is a crucial component of comprehensive plant safety strategies, contributing significantly to regulatory compliance and risk mitigation efforts.

Meeting Regulatory Standards

YBX5 motors are designed and certified to meet stringent international and national safety standards for hazardous locations. This includes compliance with ATEX directives in Europe, NEC standards in North America, and IECEx certifications globally.

Risk Assessment and Hazard Analysis

The utilize of explosion-proof engines like the YBX5 arrangement is frequently a coordinate result of exhaustive hazard appraisals and danger examinations. These engines address particular distinguished dangers in regions where combustible substances are show, shaping a key portion of a facility's generally hazard moderation strategy.

Integration with Safety Systems

YBX5 motors can be coordinated with broader plant security frameworks, counting crisis shutdown methods, alarm systems, and checking hardware. This integration improves the by and large security framework of the facility.

Reducing the Potential for Catastrophic Failure and Protecting Personnel

The implementation of YBX5 explosion-proof motors significantly reduces the risk of catastrophic failures in hazardous environments, directly contributing to the protection of personnel and assets.

Containment of Potential Ignition Sources

By successfully containing potential start sources, YBX5 engines minimize the probability of blasts that seem lead to disastrous disappointments. This control is significant in anticipating chain responses that might result in broad harm and injuries.

Enhanced Durability and Reliability

The strong development of YBX5 engines not as it were gives blast assurance but too improves by and large solidness and unwavering quality. This diminishes the chance of unforeseen disappointments that may compromise security or disturb operations.

Protection of Personnel

The use of explosion-proof engines altogether improves the security of staff working in unsafe areas. By anticipating blasts and containing potential start sources, these engines make a more secure working environment, decreasing the chance of injuries or fatalities.

Implementing a Safety-First Culture with Reliable YBX5 Motor Infrastructure

Adopting YBX5 explosion-proof motors as part of a facility's infrastructure plays a crucial role in fostering a safety-first culture within an organization.

Visible Commitment to Safety

The investment in high-quality explosion-proof equipment like YBX5 motors demonstrates a tangible commitment to safety. This visible dedication can help reinforce the importance of safety practices among employees at all levels.

Training and Awareness

The implementation of YBX5 motors provides opportunities for enhanced safety training and awareness programs. Educating employees about the function and importance of explosion-proof equipment can lead to better overall safety consciousness.

Continuous Improvement

Regular maintenance and inspection of YBX5 motors can be integrated into broader safety improvement initiatives. This ongoing attention to safety equipment reinforces the importance of continuous vigilance and improvement in safety practices.

Conclusion

The execution of ybx5 explosion-proof motors is a basic step in improving working environment security in dangerous mechanical situations. These specialized engines successfully contain potential start sources, contribute to general plant security compliance, and play an imperative part in hazard relief techniques. By lessening the potential for disastrous disappointments and ensuring faculty, YBX5 engines offer assistance make a more secure work environment and cultivate a culture of security inside organizations.

As businesses proceed to prioritize security and administrative compliance, the use of explosion-proof hardware like YBX5 engines becomes progressively critical. Their integration into mechanical forms not only improves security but also contributes to operational unwavering quality and peace of mind for both bosses and workers working in unsafe locations.

FAQ

1. Q: What makes YBX5 motors explosion-proof?

A: YBX5 engines are planned with flameproof walled in areas and weight-alleviation joints that contain inside blasts and anticipate fire spreading to the outside climate. They are developed with materials that restrain surface temperatures and join highlights to minimize inactive power buildup.

2. Q: In which industries are YBX5 explosion-proof motors commonly used?

A: Ybx5 explosion-proof motors are commonly utilized in businesses where combustible gases, vapors, or liquids are displayed. This incorporates oil and gas, chemical handling, mining, pharmaceutical manufacturing, and certain regions of food and refreshment production.

3. Q: How often should YBX5 explosion-proof motors be inspected?

A: The review recurrence for ybx5 explosion-proof motors depends on the particular application and environment. By and large, visual assessments ought to be conducted routinely, with more comprehensive reviews and upkeep performed every year or as prescribed by the producer and pertinent industry standards.

Experience the Safety and Reliability of XCMOTOR's YBX5 Explosion-Proof Motors

At XCMOTOR, we understand the critical importance of safety in hazardous industrial environments. Our YBX5 explosion-proof motors are engineered to provide superior protection and reliability, ensuring your workplace remains safe and compliant. With our extensive experience and commitment to quality, we offer tailored solutions to meet your specific needs.

Don't compromise on safety. Choose XCMOTOR as your trusted YBX5 explosion-proof motor supplier. Contact us today at xcmotors@163.com to learn how our expertise can enhance your facility's safety infrastructure.

References

1. International Electrotechnical Commission. (2020). "IEC 60079: Explosive Atmospheres - Equipment Protection by Flameproof Enclosures."

2. National Fire Protection Association. (2021). "NFPA 70: National Electrical Code, Article 500: Hazardous (Classified) Locations."

3. European Committee for Electrotechnical Standardization. (2019). "EN 60079-1: Explosive Atmospheres - Equipment Protection by Flameproof Enclosures 'd'."

4. Occupational Safety and Health Administration. (2022). "Hazardous Locations - Classification of Hazardous Locations."

5. Institute of Electrical and Electronics Engineers. (2021). "IEEE 1349: Guide for the Application of Electric Motors in Class I, Division 2 and Class I, Zone 2 Hazardous (Classified) Locations."

6. American Petroleum Institute. (2020). "API RP 500: Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities."