Guide to 4000 kW Motor Specifications

When it comes to controlling large-scale mechanical applications, 4000 kw motors play a pivotal part. These high-capacity engines are fundamental for driving overwhelming apparatus, controlling expansive pumps, and supporting different mechanical forms. In this comprehensive document, we'll investigate the key determinations and considerations for 4000 kw motors, making a difference you make educated choices for your power-intensive applications.

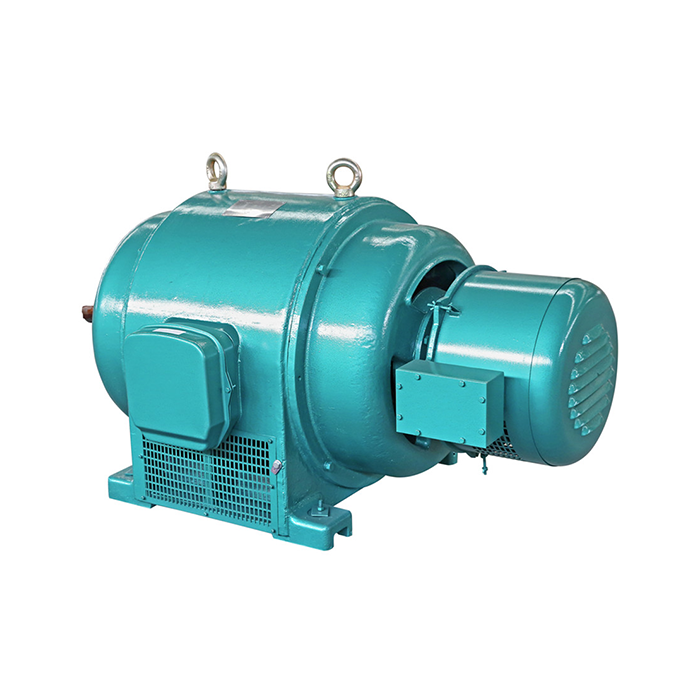

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What Are the Key Electrical and Mechanical Parameters of a 4000 kW Motor?

Understanding the electrical and mechanical parameters of a 4000 kW motor is crucial for selecting the right motor for your application. These parameters define the motor's performance characteristics and operational limits.

Electrical Parameters

The primary electrical parameters of a 4000 kW motor include:

- Voltage: Ordinarily extending from 3.3 kV to 13.8 kV for engines of this size

- Current: The appraised current draw, which changes based on voltage and control factor

- Frequency: Ordinarily 50 Hz or 60 Hz, depending on the region

- Power Calculate: Ordinarily extending from 0.85 to 0.95 for huge motors

- Efficiency: Frequently surpassing 96% for cutting edge high-efficiency motors

Mechanical Parameters

Key mechanical parameters include:

- Speed: Regularly extending from 1000 to 3600 RPM, depending on the post configuration

- Torque: The appraised torque yield, which is contrarily corresponding to speed

- Frame Measure: Decides the physical measurements and mounting options

- Weight: Can surpass 20 tons for engines of this capacity

- Cooling Strategy: Frequently utilizing constrained discuss or water cooling systems

These parameters work together to characterize the motor's general execution and appropriateness for particular applications. For example, a 4000 kw motor working at 3000 RPM will have distinctive torque characteristics compared to one running at 1500 RPM, in spite of having the same control rating.

Decoding Voltage Ratings, Frequency, and Efficiency Classes (IE3/IE4) for 4000 kW Motors

When selecting a 4000 kW motor, understanding voltage ratings, frequency, and efficiency classes is essential for ensuring optimal performance and energy savings.

Voltage Ratings

4000 kW motors are typically available in medium voltage ranges:

- 3.3 kV

- 6.6 kV

- 11 kV

- 13.8 kV

The choice of voltage rating depends on your facility's electrical foundation and the particular application necessities. Higher voltage evaluations by and large, permit for lower current draw, decreasing cable measure necessities and control losses.

Frequency

Most industrial 4000 kW motors operate at either:

- 50 Hz (common in Europe, Asia, and Africa)

- 60 Hz (standard in North America and parts of South America)

The operating frequency affects the motor's speed and torque characteristics. For instance, a 4-pole motor will run at approximately 1500 RPM at 50 Hz and 1800 RPM at 60 Hz.

Efficiency Classes

Energy effectiveness is a basic thought for expansive engines. The Universal Electrotechnical Commission (IEC) characterizes effectiveness classes for electric motors:

- IE3 (Premium Efficiency)

- IE4 (Super Premium Efficiency)

For 4000 kw motors, the contrast between IE3 and IE4 productivity levels can result in noteworthy vitality reserve funds over the motor's lifetime. Whereas IE4 engines may have a higher starting efficiency, they frequently give a superior return on speculation through decreased energy consumption.

When assessing productivity, it's vital to consider the motor's obligation cycle and stack profile. A engine working ceaselessly at full stack will advantage more from higher effectiveness evaluations compared to one that runs irregularly or at fractional loads.

Essential Frame Sizes, Mounting Options, and Enclosure Types (IP, IC) Explained

The physical characteristics of a 4000 kW motor are just as important as its electrical specifications. Understanding frame sizes, mounting options, and enclosure types is crucial for ensuring proper installation and operation.

Frame Sizes

Frame sizes for 4000 kW motors are typically custom-designed due to their large capacity. However, they often follow IEC standards for consistency. Common frame designations might include:

- IEC 800

- IEC 900

- IEC 1000

The outline measure decides the motor's physical measurements, shaft stature, and mounting gap designs. It's basic to guarantee compatibility with your existing gear and establishment space.

Mounting Options

Large motors like 4000 kW units often use specific mounting configurations:

- Horizontal Foot Mounted (IM B3)

- Vertical Flange Mounted (IM V1)

- Horizontal Flange Mounted (IM B5)

The choice of mounting choice depends on the application necessities and accessible space. Appropriate arrangement and secure mounting are basic for anticipating vibration issues and guaranteeing long-term reliability.

Enclosure Types

Enclosure types are defined by IP (Ingress Protection) and IC (International Cooling) codes:

- IP55: Dust-protected and protected against water jets

- IP56: Dust-protected and protected against powerful water jets

- IC411: Totally enclosed fan-cooled (TEFC)

- IC81W: Totally enclosed water-cooled (TEWC)

The choice of a walled-in area sort depends on the working environment and cooling requirements. For occasion, a engine working in a dusty environment might require an IP56 rating, whereas an engine in a clean, temperature-controlled room may utilize an IP55 enclosure.

Understanding Starting Torque, Speed Range, and Power Factor in High-Power Motor Selection

Selecting the right 4000 kw motor includes cautious thought of beginning torque, speed range, and control figure. These variables altogether affect the motor's execution and compatibility with your application.

Starting Torque

Starting torque is significant for applications that require a tall introductory drive to overcome idleness. For 4000 kw motors, normal beginning torque characteristics include:

- Direct-on-line (DOL) starting: 0.6 to 1.5 times rated torque

- Star-delta starting: Reduced starting torque, typically 0.3 to 0.5 times rated torque

- Soft starter: Adjustable starting torque, usually 0.2 to 0.7 times rated torque

The choice of beginning strategy depends on your application's prerequisites and the capabilities of your control supply framework. Tall beginning torque can cause mechanical stretch and voltage plunges, so it's basic to adjust beginning execution with framework constraints.

Speed Range

While many 4000 kW motors operate at fixed speeds, some applications require variable speed operation. Speed range considerations include:

- Base speed: Typically 1000, 1500, or 3000 RPM for 50 Hz systems

- Variable speed range: Often 10:1 or 20:1 for variable frequency drive (VFD) applications

- Constant torque range: Usually up to base speed

- Constant power range: Above base speed, where torque decreases as speed increases

Understanding your application's speed requirements is crucial for selecting the right motor and drive system combination.

Power Factor

Power calculation is a measure of how productively an engine employments electrical control. For 4000 kW motors:

- Typical power factor range: 0.85 to 0.95 at full load

- Impact on system efficiency: Higher power factor reduces reactive power demand

- Correction methods: Power factor correction capacitors or active front end drives

A higher control figure decreases electrical framework misfortunes and may offer assistance in dodging utility punishments for moo control figure. When selecting an engine, consider its control figure characteristics and any essential rectification measures.

How to Read and Interpret a 4000 kW Motor Datasheet for Your Application?

Interpreting a datasheet for a 4000 kw motor requires a careful understanding of different specialized parameters. Here's a direct to offer assistance you explore through the key information:

Basic Motor Information

- Power Rating: Confirm it's 4000 kW

- Voltage: Check if it matches your system voltage

- Frequency: Verify compatibility with your power supply (50 Hz or 60 Hz)

- Speed: Note the rated speed and any speed range information

- Frame Size: Ensure it fits your installation requirements

Performance Data

- Efficiency: See for IE3 or IE4 appraisals and particular effectiveness values at distinctive stack points

- Power Calculate: Check the control calculation at full and halfway loads

- Current: Note the full stack current and beginning current

- Torque: Look at the beginning, breakdown, and full-stack torque values

Thermal and Environmental Specifications

- Insulation Course: As a rule, Course F or H for huge motors

- Temperature Rise: Ought to be inside the limits of the separator class

- Ambient Temperature: Confirm it matches your working environment

- Altitude: Check if any derating is fundamental for high-altitude installations

When translating the datasheet, consider how each parameter adjusts with your particular application prerequisites. Pay extraordinary consideration to any comments or extra data that may give setting for the recorded specifications.

Conclusion

Selecting the right 4000 kw motor for your application requires a exhaustive understanding of electrical and mechanical parameters, voltage evaluations, effectiveness classes, outline sizes, mounting choices, walled-in area sorts, beginning torque, speed extend, and control calculate. By carefully considering these components and precisely deciphering engine datasheets, you can guarantee ideal execution, vitality productivity, and unwavering quality in your high-power mechanical applications.

Remember that whereas this direct gives a comprehensive outline, each application has special necessities. It's continuously fitting to counsel with engine specialists or producers to guarantee the best choice for your particular needs.

FAQ

1. Q: What are the main advantages of using a 4000 kW motor in industrial applications?

A: 4000 kw motors offer tall control yield for large-scale mechanical forms, great proficiency for vitality reserve funds, and vigorous development for long-term unwavering quality. They are perfect for applications requiring steady tall control, such as huge pumps, compressors, and overwhelming machinery.

2. Q: How does the efficiency of a 4000 kW motor compare to smaller motors?

A: By and large, 4000 kw motors have higher effectiveness evaluations compared to smaller engines. They frequently accomplish productivity levels of 96% or higher, particularly when appraised as IE3 or IE4. This tall effectiveness translates to noteworthy vitality investment funds over the motor's lifetime, especially in continuous operation scenarios.

3. Q: What are the key maintenance considerations for a 4000 kW motor?

A: Upkeep of 4000 kw motors ordinarily includes customary reviews of bearings, windings, and cooling systems. Vibration checking, arrangement checks, and grease are significant. Due to their measure and complexity, these engines regularly require specialized support strategies and may advantage from prescient support methods to guarantee ideal execution and longevity.

Expert Solutions for Your 4000 kW Motor Needs

At XCMOTOR, we specialize in giving high-quality, productive 4000 kw motors custom-fitted to your particular mechanical necessities. Our group of experienced engineers is devoted to making a difference. You select the ideal engine for your application, guaranteeing ideal execution and vitality savings. With our comprehensive range of 4000 kw motors and customization choices, we can meet the most demanding specifications.

Don't let motor selection challenges hinder your project's success. Contact XCMOTOR today at xcmotors@163.com to discuss your 4000 kW motor needs. As a leading 4000 kW motor supplier, we're committed to powering your success with reliable, efficient, and innovative motor solutions.

References

1. International Electrotechnical Commission. (2021). "IEC 60034-30-1: Rotating electrical machines - Part 30-1: Efficiency classes of line operated AC motors."

2. IEEE Industry Applications Society. (2019). "IEEE 841: Standard for Petroleum and Chemical Industry—Premium-Efficiency, Severe-Duty, Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors."

3. Almeida, A., et al. (2020). "Motor Systems for Energy Efficiency and Decarbonization." European Copper Institute.

4. Benhaddadi, M., et al. (2018). "Electric Motors for Energy Efficiency: Design and Applications." Wiley-IEEE Press.

5. U.S. Department of Energy. (2022). "Improving Motor and Drive System Performance: A Sourcebook for Industry."

6. European Committee of Manufacturers of Electrical Machines and Power Electronics. (2021). "Guide to the Selection and Application of Large AC Motors."

7. International Energy Agency. (2023). "Energy Efficiency in Electric Motor-Driven Systems: Policy Guidelines and Best Practices."