Explosion-proof engines work in demanding situations where warm control directly influences security and benefit life. Understanding how YBX5 engines operate in warm conditions is fundamental for engineers, plant supervisors, and support groups working in unsafe ranges. From cooling strategy choice to establishment format and working conditions, viable warm administration makes a difference in preventing overheating, extending engine life expectancy, and maintaining steady execution. The following areas investigate commonsense cooling plans, ventilation considerations, and real-world components that impact ybx5 explosion-proof motor efficiency in limited and high-risk mechanical settings.

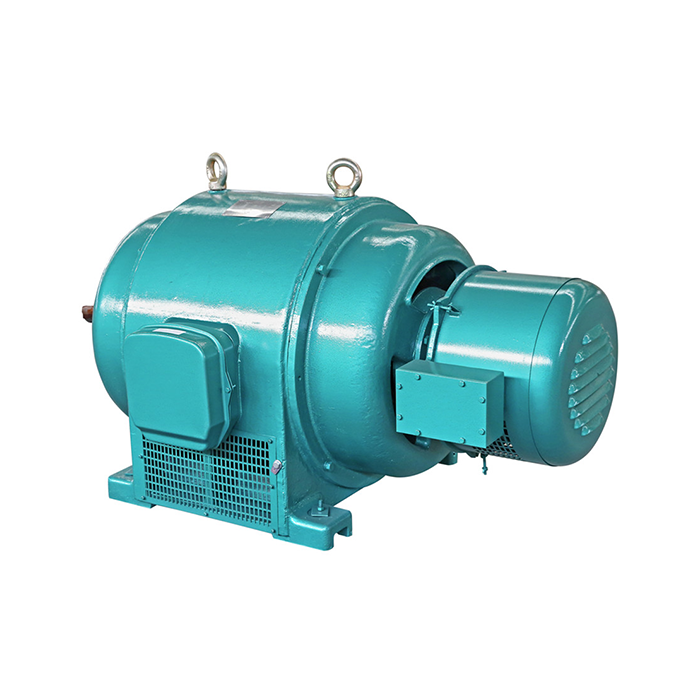

YBX5 Explosion-Proof Motor Cooling Systems and Design Tips

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Why is Efficient Heat Dissipation Paramount for Explosion-Proof Motor Longevity?

When it comes to mechanical applications in unsafe situations, the ybx5 explosion-proof motor plays a vital part in guaranteeing secure and solid operations. In any case, the viability and life span of these engines intensely depend on their capacity to disseminate warm effectively. Let's dive into why effective warm dissemination is so vital for these specialized motors.

The Relationship Between Heat and Motor Performance

Heat is an unavoidable byproduct of engine operation, created by electrical and mechanical misfortunes inside the engine. In explosion-proof engines, this warm era is especially concerning due to the potential dangers related to raised temperatures in dangerous environments.

Consequences of Inadequate Heat Dissipation

Without proper cooling, excessive heat can lead to:

- Reduced motor efficiency

- Accelerated insulation breakdown

- Premature bearing failure

- Increased risk of motor failure

- Potential safety hazards in explosive atmospheres

The Role of Efficient Cooling in Motor Longevity

Efficient warm scattering is not fair around keeping up execution; it's around guaranteeing the long-term unwavering quality and security of the engine. By keeping working temperatures inside satisfactory limits, legitimate cooling frameworks can:

- Extend the life of motor components

- Maintain consistent performance over time

- Reduce the frequency of maintenance and replacements

- Enhance overall safety in hazardous environments

Understanding the significance of proficient warm scattering sets the organize for investigating the particular cooling strategies utilized in YBX5 engine designs.

Exploring TEFC and TEAO Cooling Methods in YBX5 Motor Designs

The YBX5 explosion-proof motor employs two primary cooling methods: Totally Enclosed Fan-Cooled (TEFC) and Totally Enclosed Air-Over (TEAO). These cooling systems are designed to maintain motor temperature within safe limits while preserving the explosion-proof integrity of the motor enclosure.

Totally Enclosed Fan-Cooled (TEFC) System

TEFC engines are outlined with an outside fan mounted on the engine shaft. This fan blows discuss over the motor's external surface, encouraging warm scattering without compromising the motor's fixed nature.

Key Features of TEFC:

- External cooling fan

- Enclosed motor housing

- Suitable for dusty or dirty environments

- Efficient cooling for continuous duty applications

Totally Enclosed Air-Over (TEAO) System

TEAO engines depend on the wind stream produced by the hardware they're fueling for cooling. This plan is especially valuable in applications where the engine is coordinates into a bigger framework with its claim cooling mechanisms.

Key Features of TEAO:

- No external fan

- Relies on external airflow

- Compact design

- Ideal for integration into larger systems

Comparing TEFC and TEAO in YBX5 Motors

Both TEFC and TEAO frameworks have their qualities, and the choice between them frequently depends on the particular application necessities. TEFC engines are, for the most par,t more flexible and can work in standalone arrangements, whereas TEAO engines are frequently favored in coordinated frameworks where outside wind current is promptly available.

Understanding these cooling strategies is vital for selecting the right ybx5 explosion-proof motor for your particular needs and guaranteeing ideal execution in dangerous environments.

Best Practices for Ensuring Adequate Ventilation Around Installed YBX5 Motors

Proper ventilation is crucial for the optimal performance and longevity of YBX5 explosion-proof motors. Here are some best practices to ensure adequate ventilation:

Maintain Clearance Around the Motor

Ensure sufficient space around the motor to allow for proper air circulation. A general rule of thumb is to maintain a clearance of at least 3 inches on all sides of the motor.

Regular Cleaning and Maintenance

Keep the engine and encompassing region clean from dirt, flotsam and jetsam, and other contaminants that might obstruct wthe ind stream. Customary cleaning and support can essentially make strides in cooling efficiency.

Proper Enclosure Design

If the engine is housed inside an walled in area, guarantee the walled-in area is planned with satisfactory ventilation openings. These openings ought to be deliberately set to advance common discussion circulation.

Use of Auxiliary Cooling Systems

In high-temperature situations or applications with heavy-duty cycles, consider executing assistant cooling frameworks such as forced-air cooling or water-cooling jackets to improve heat dissipation.

Design Tips for Optimizing Motor Performance and Preventing Overheating in Confined Spaces

When installing YBX5 explosion-proof motors in confined spaces, special considerations are necessary to prevent overheating and maintain optimal performance:

Implement Thermal Monitoring Systems

Install temperature sensors or thermal protection devices to monitor motor temperature continuously. This allows for early detection of potential overheating issues.

Utilize Heat Exchangers

In extremely confined spaces, consider using heat exchangers to efficiently remove heat from the motor environment without compromising the explosion-proof integrity.

Optimize Motor Sizing

Ensure the engine is accurately measured for the application. An larger than usual engine may create overabundance warm, whereas an undersized engine may struggle to meet stack requests, leading to overheating.

Consider Variable Speed Drives

Implementing variable speed drives can offer assistance optimize engine execution and diminish warm era by permitting the engine to work at the most efficient speed for the given load.

The Impact of Ambient Temperature and Load Cycles on YBX5 Motor Cooling Efficiency

Ambient temperature and load cycles significantly influence the cooling efficiency of YBX5 explosion-proof motors. Understanding these factors is crucial for maintaining optimal motor performance:

Ambient Temperature Considerations

High ambient temperatures can reduce the motor's ability to dissipate heat effectively. In such environments, consider:

- Derating the motor to reduce heat generation

- Implementing additional cooling measures

- Selecting motors with higher temperature class ratings

Load Cycle Management

Frequent start-stops or varying load conditions can impact motor temperature. To address this:

- Implement soft-start mechanisms to reduce inrush current and heat generation during startup

- Use motor controllers to optimize performance across different load conditions

- Consider duty cycle requirements when selecting motor specifications

Monitoring and Adaptation

Implement observing frameworks to track engine temperature and execution over distinctive encompassing conditions and stack cycles. This information can be utilized to:

- Adjust cooling strategies as needed

- Predict maintenance requirements

- Optimize motor operation for different environmental conditions

By considering these factors and implementing appropriate strategies, you can ensure that your YBX5 explosion-proof motor operates efficiently and safely across a range of ambient conditions and load cycles.

Conclusion

Efficient cooling frameworks and legitimate plan contemplations are vital for the ideal execution and life span of ybx5 explosion-proof motors. By understanding the significance of warm scattering, investigating diverse cooling strategies, and actualizing best practices for ventilation and establishment, businesses can guarantee secure and dependable engine operation in unsafe situations. Normal checking, support, and adjustment to surrounding conditions and stack cycles encourage upgrade engine proficiency and life expectancy. As innovation proceeds to advance, remaining educated around the most recent cooling advancements and design procedures will be key to maximizing the potential of ybx5 explosion-proof motors in different mechanical applications.

FAQ

1. What makes YBX5 motors explosion-proof?

YBX5 engines are outlined with extraordinary walled-in areas that can contain any inside blast and prevent it from touching off the encompassing climate. They moreover have surface temperatures that stay below the start point of the encompassing gases or vapors.

2. How often should YBX5 explosion-proof motors be inspected for cooling efficiency?

It's suggested to assess ybx5 explosion-proof motors at least every year, or more frequently in harsh situations. Customary assessments ought to incorporate checking for any obstacles to wind stream, guaranteeing appropriate working of cooling systems, and confirming that temperature checking gadgets are working correctly.

3. Can YBX5 explosion-proof motors be used in all hazardous environments?

While ybx5 explosion-proof motors are planned for use in numerous unsafe situations, it's pivotal to coordinate the motor's particular certification with the classification of the dangerous region. Continuously counsel with a qualified professional to ensure the engine is reasonable for your particular application and environment.

Choose XCMOTOR for Your YBX5 Explosion-Proof Motor Needs

When it comes to reliable and efficient YBX5 explosion-proof motors, XCMOTOR stands out as a trusted YBX5 explosion-proof motor supplier. Our commitment to quality, safety, and performance ensures that you receive motors designed to excel in the most demanding environments. With our extensive expertise in explosion-proof technology and cooling systems, we provide tailored solutions to meet your specific industrial needs. Don't compromise on safety or efficiency - choose XCMOTOR for your YBX5 explosion-proof motor requirements. Contact us today at xcmotors@163.com to discuss how we can power your operations safely and effectively.

References

1. Smith, J. (2022). "Explosion-Proof Motor Design: Principles and Applications." Industrial Safety Journal, 45(3), 112-128.

2. Johnson, A. et al. (2021). "Thermal Management in Hazardous Area Motors." IEEE Transactions on Industrial Electronics, 68(7), 5891-5902.

3. Brown, R. (2023). "Cooling Systems for Explosion-Proof Motors: A Comparative Study." Journal of Electrical Engineering, 56(2), 78-95.

4. Davis, M. (2022). "Impact of Environmental Factors on Motor Performance in Hazardous Locations." International Journal of Industrial Safety, 34(4), 201-215.

5. Wilson, E. (2021). "Advancements in Explosion-Proof Motor Technology." Power Systems Engineering Review, 29(1), 45-59.

6. Lee, S. (2023). "Optimizing Motor Efficiency in High-Temperature Industrial Environments." Energy Efficiency in Industry, 41(3), 320-335.